Preparation technology and production line of high-purity tea polyphenol

A preparation process and technology of tea polyphenols, which is applied in the field of high-purity tea polyphenols preparation process and production line, can solve the problems of high caffeine content and difficult drug raw materials, and achieve the effects of less elution of impurities, short extraction time, and lower content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

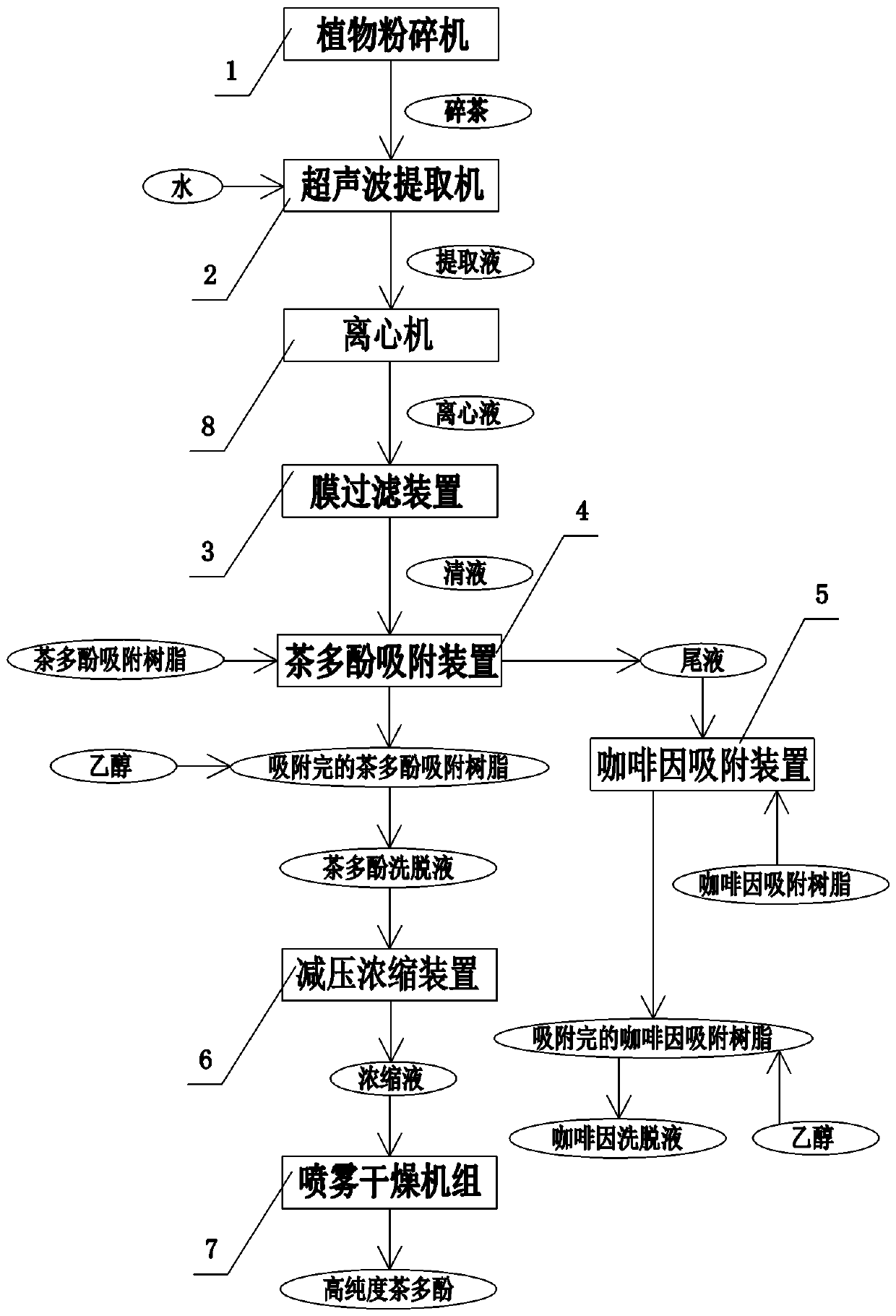

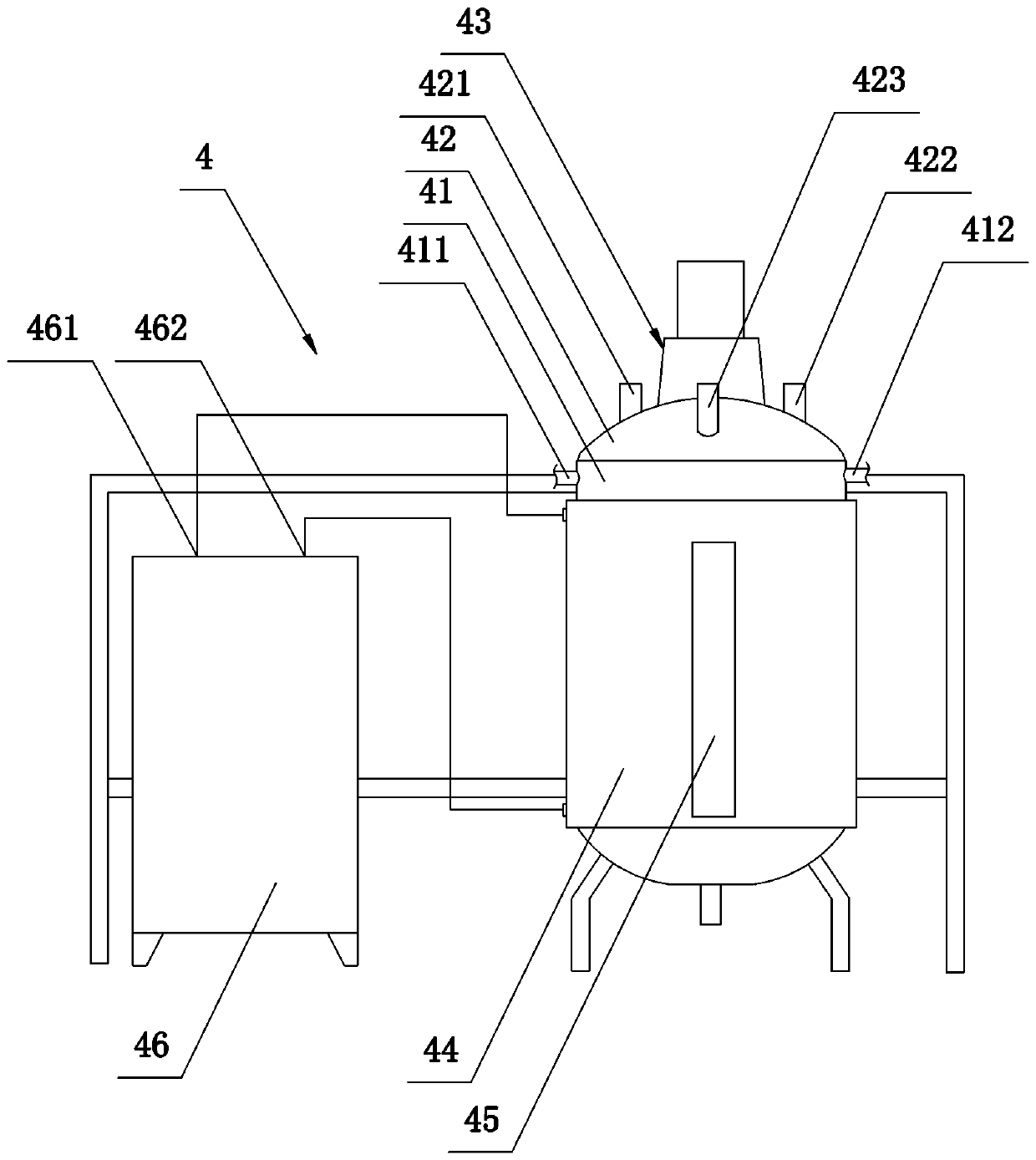

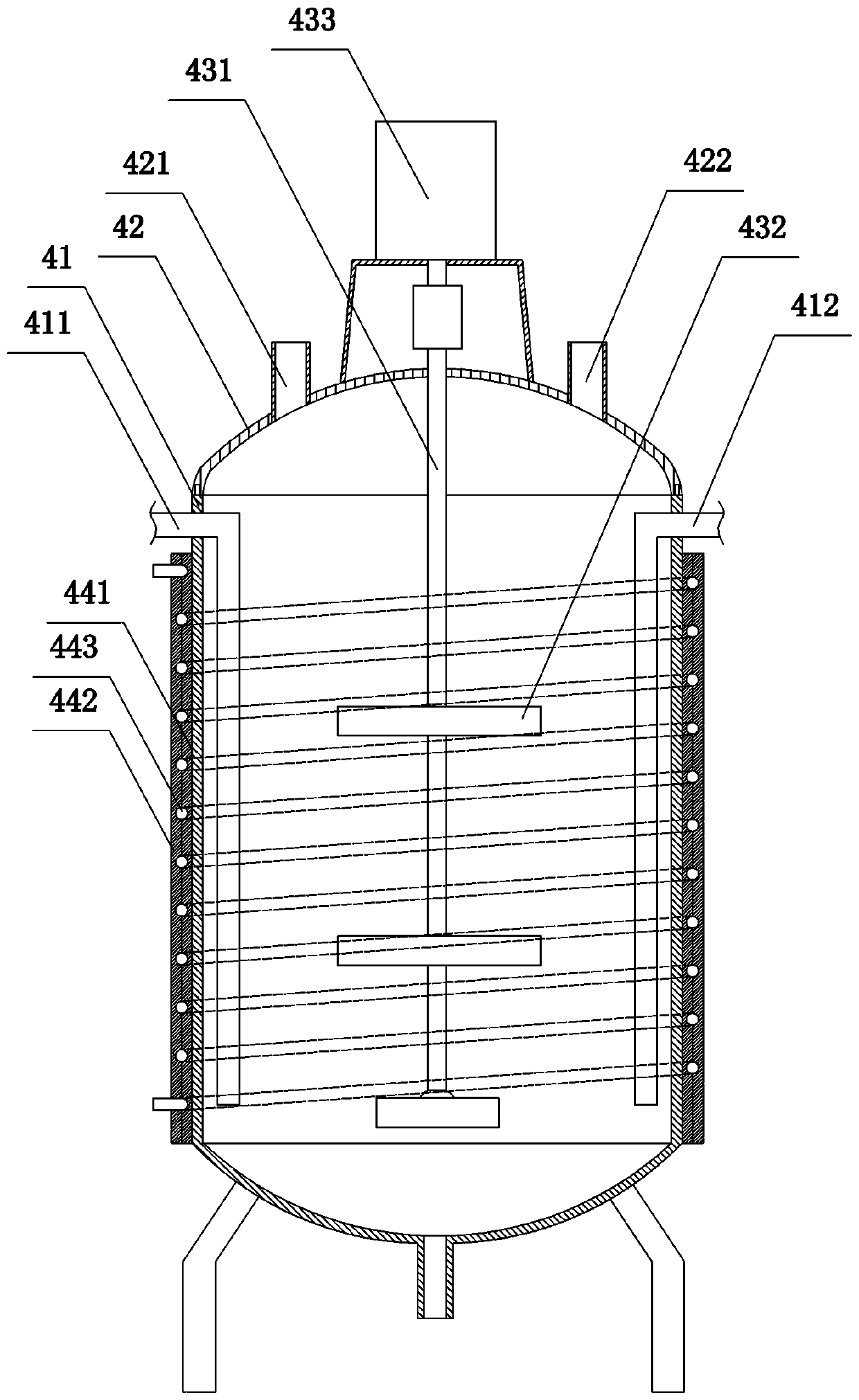

[0037] refer to figure 1 , figure 2 with image 3 . A preparation process of high-purity tea polyphenols, comprising the following steps:

[0038] 1) crushing: crushing the tea leaves to be processed by the plant crusher 1 to obtain crushed tea;

[0039] 2) Water extraction: put the crushed tea and water into the ultrasonic extractor 2 at a ratio of 1:20 for extraction to obtain an extract;

[0040] 3) centrifugation: transport the extract to a centrifuge 8 for centrifugation to obtain a centrifuge;

[0041] 4) Fine filtration: transport the centrate to the membrane filtration device 3 for membrane filtration treatment to obtain clear liquid;

[0042] 5) Adsorption: mixing the clear liquid with a tea polyphenol adsorption resin, so that the tea polyphenol adsorption resin absorbs the tea polyphenols in the clear liquid; the tea polyphenol adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com