Foam coffee alcohol fermentation beverage and preparation method thereof

A technology of alcohol fermentation and coffee, applied in the direction of coffee extraction, to achieve the effects of stable fermentation speed, strong flavor and a wide range of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

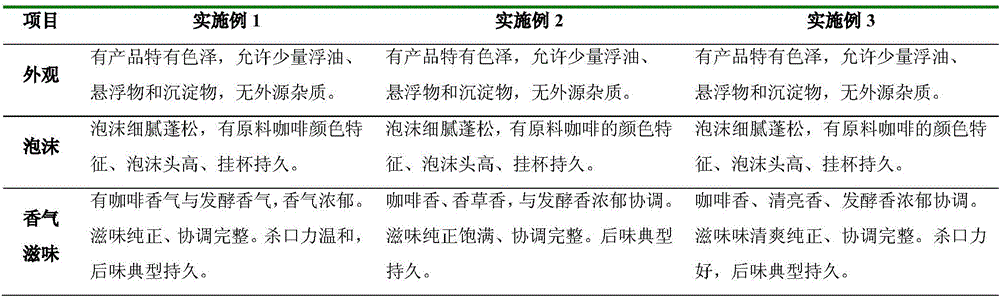

Embodiment 1

[0026] 1. Preparation of coffee sugar solution

[0027] After the decaffeinated roasted coffee beans are ground, dissolve and extract the decaffeinated coffee powder with boiling water to obtain a coffee solution, add brown sugar while it is hot, and adjust the solid concentration of the coffee sugar solution to 1.0% (mass ratio, m / m), The sugar concentration was 12% (mass ratio, m / m). Fully dissolve the coffee sugar solution, and cool to 16°C for later use.

[0028] 2. Inoculation and fermentation

[0029] Add commercially available active dry Saccharomyces cerevisiae into the coffee sugar solution prepared in step 1). For the usage method of active dry Saccharomyces cerevisiae, please refer to the product instructions. The concentration of yeast cells in the coffee sugar solution after inoculation should not be lower than 2×10 7 cell / mL, and closed fermentation in a fermenter at 16°C until the alcohol content in the fermentation broth is 3.0% (v / v), CO 2 The content is ...

Embodiment 2

[0034] 1. Preparation of coffee sugar solution

[0035] Dissolve decaffeinated instant coffee and high fructose syrup with boiling water, adjust the solids concentration of coffee sugar solution to 2.0% (mass ratio, m / m), and sugar concentration to 5% (mass ratio, m / m), fully dissolve to obtain coffee sugar solution and cooled to 14°C for later use.

[0036] 2. Inoculation and fermentation

[0037] Cultivate fresh and live Saccharomyces cerevisiae according to the conventional culture method. After the cultured seed yeast is washed with sterile water, filtered or centrifuged (to eliminate the influence of the culture medium on product quality) to remove the residual culture medium, it is inserted into the coffee prepared in step 1). in the sugar solution. The concentration of yeast cells in the coffee sugar solution after inoculation should not be lower than 2×10 7 cell / mL, and fermented in a fermenter at 14°C until CO 2 The content is 2.0g / L, the alcohol content is 2.0% (...

Embodiment 3

[0042] 1. Preparation of coffee sugar solution

[0043] Dissolve the decaffeinated coffee concentrate and white granulated sugar with boiling water, adjust the solids concentration of the coffee sugar solution to 2.4% (mass ratio, m / m), and the sugar concentration to be 10% (mass ratio, m / m), fully dissolve to obtain coffee Sugar solution and cooled to 15°C for later use.

[0044] 2. Inoculation and fermentation

[0045] Add commercially available active dry Saccharomyces cerevisiae into the coffee sugar solution prepared in step 1). Refer to the product instructions for the use of active dry Saccharomyces cerevisiae. The concentration of yeast cells in the coffee sugar solution after inoculation should not be lower than 2×10 7 cell / mL, and closed fermentation in a fermenter at 15°C until the alcohol content in the fermented liquid is 5.5% (v / v), CO 2 The content is 4.5g / L, and the temperature is rapidly cooled to 3°C, and the yeast is filtered and separated under the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com