One-way clutch

A one-way clutch, circumferential direction technology, applied in one-way clutches, clutches, mechanical equipment and other directions, can solve the problems of difficult opening edge 7b, increase manufacturing cost, reduce product yield and other problems, achieve good reproducibility, reduce costs, The effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

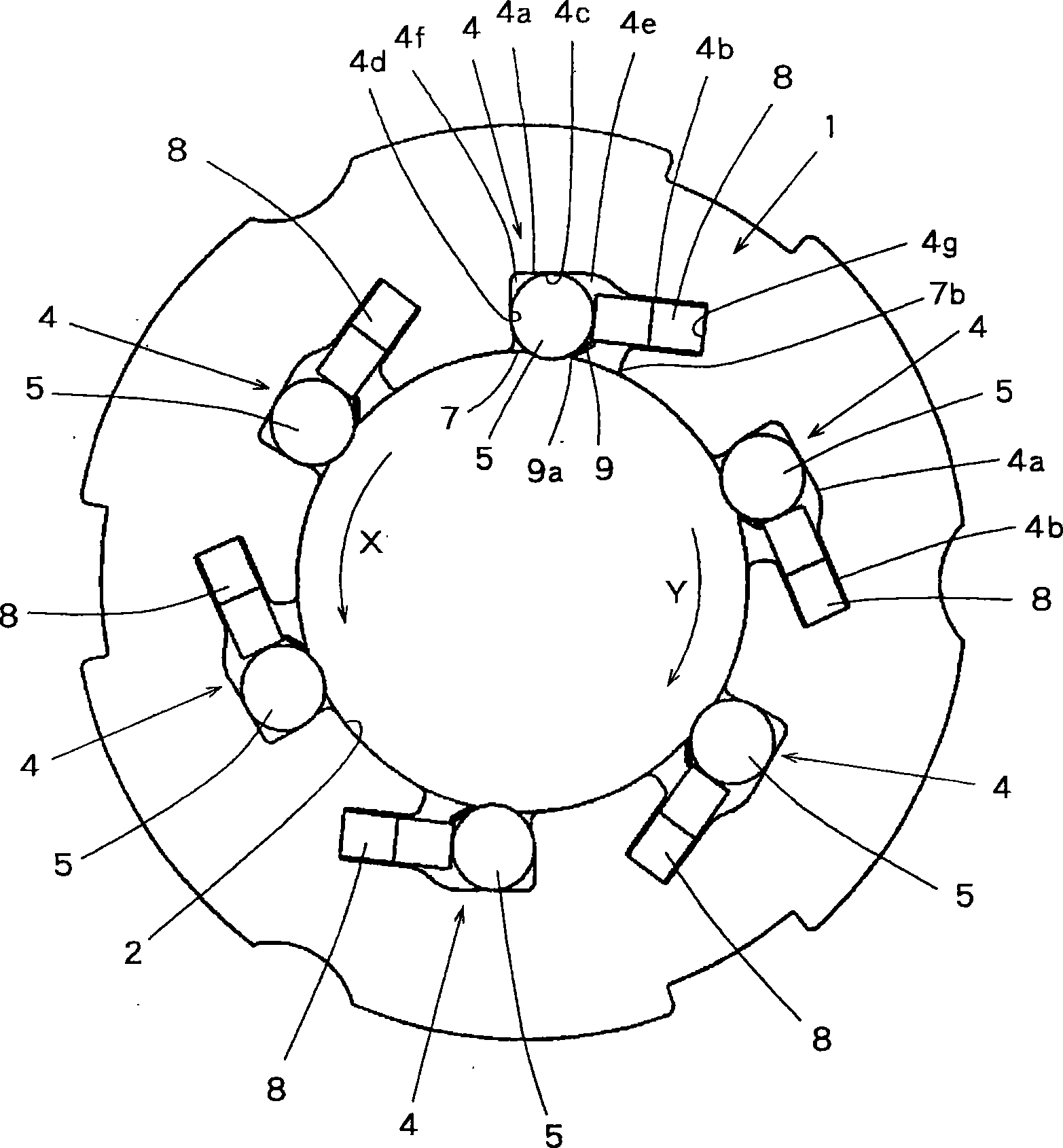

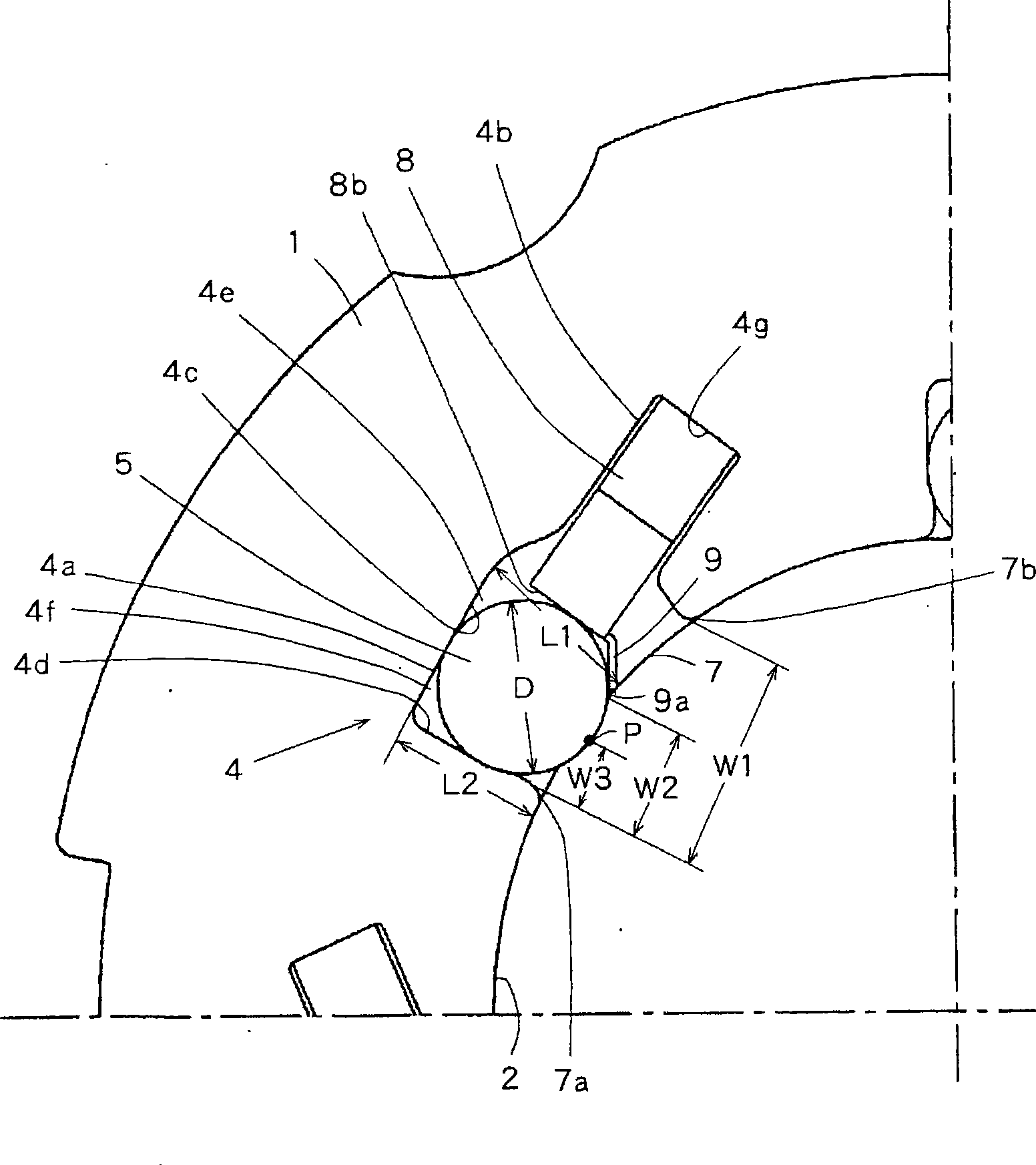

[0056] Figure 1 to Figure 5 In the shown one-way clutch of the first embodiment, a shaft hole 2 is formed in a housing 1 , and a plurality of needle roller holding spaces 4 are formed along the shaft hole 2 . The needle roller holding space 4 is constituted by a needle roller holding portion 4a into which the needle roller 5 which is a rolling member of the present invention is inserted, and a spring holding portion 4b into which the spring member 8 is inserted. In addition, the needle roller holding space 4 has a wide portion 4e and a narrow portion 4f. In this wide portion 4e, the relative distance between the outer periphery of the shaft inserted into the shaft hole 2 and the facing surface 4c is larger than the outer diameter D of the needle roller 5, while in the narrower portion 4f, it is smaller than the outer diameter D. .

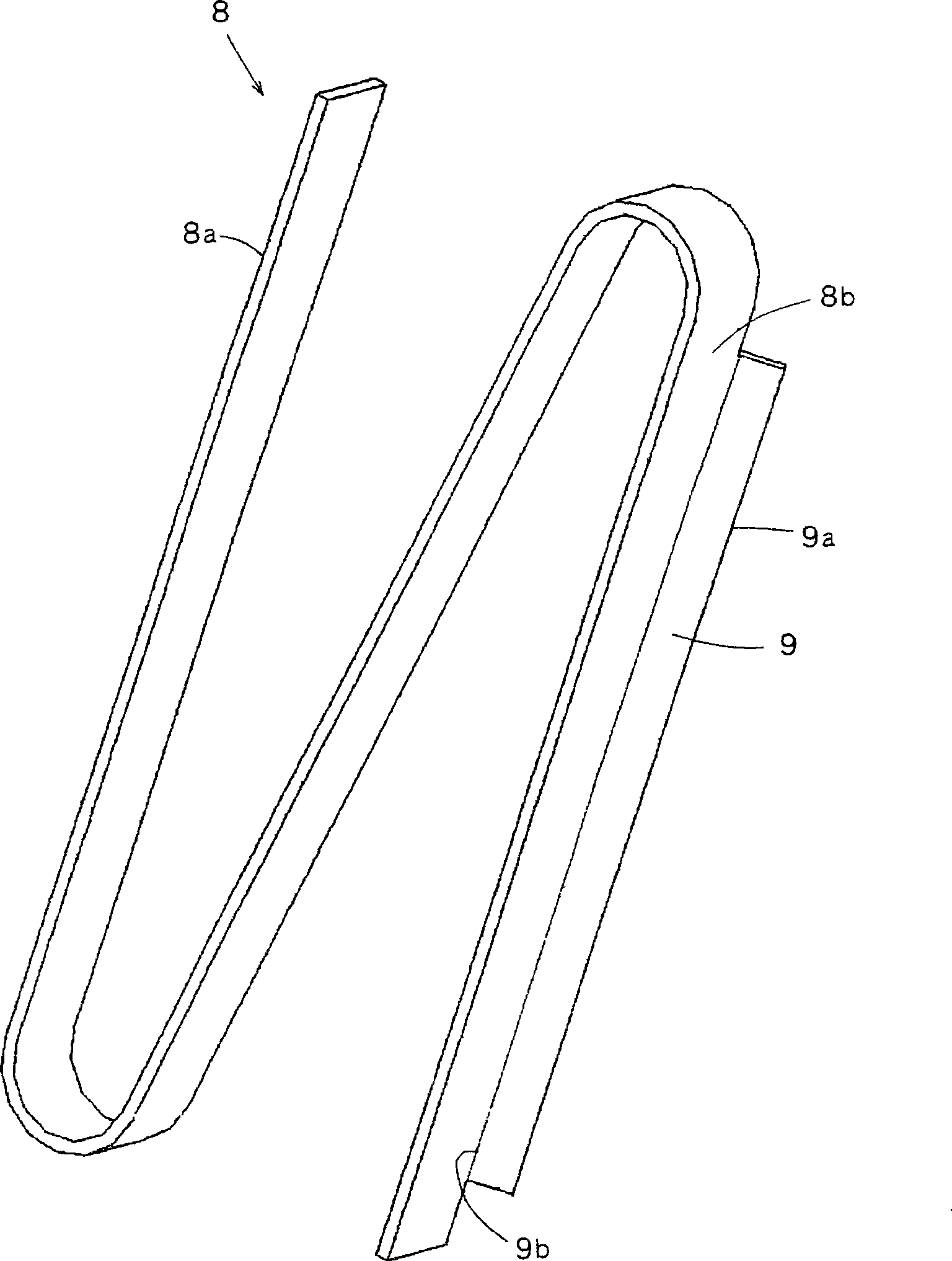

[0057] The spring member 8 used in the first embodiment is as image 3 The S-shaped metal leaf spring shown has a base end surface 8a that con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com