Bimetal joint

A bimetallic joint, welding connection technology, applied in the direction of pipe/pipe joint/pipe fitting, threaded connection, non-detachable pipe connection, etc., can solve the problems of unstable performance, low safety, long delivery time, etc. It is not easy to leak, enhance the sealing effect, and solve the leakage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

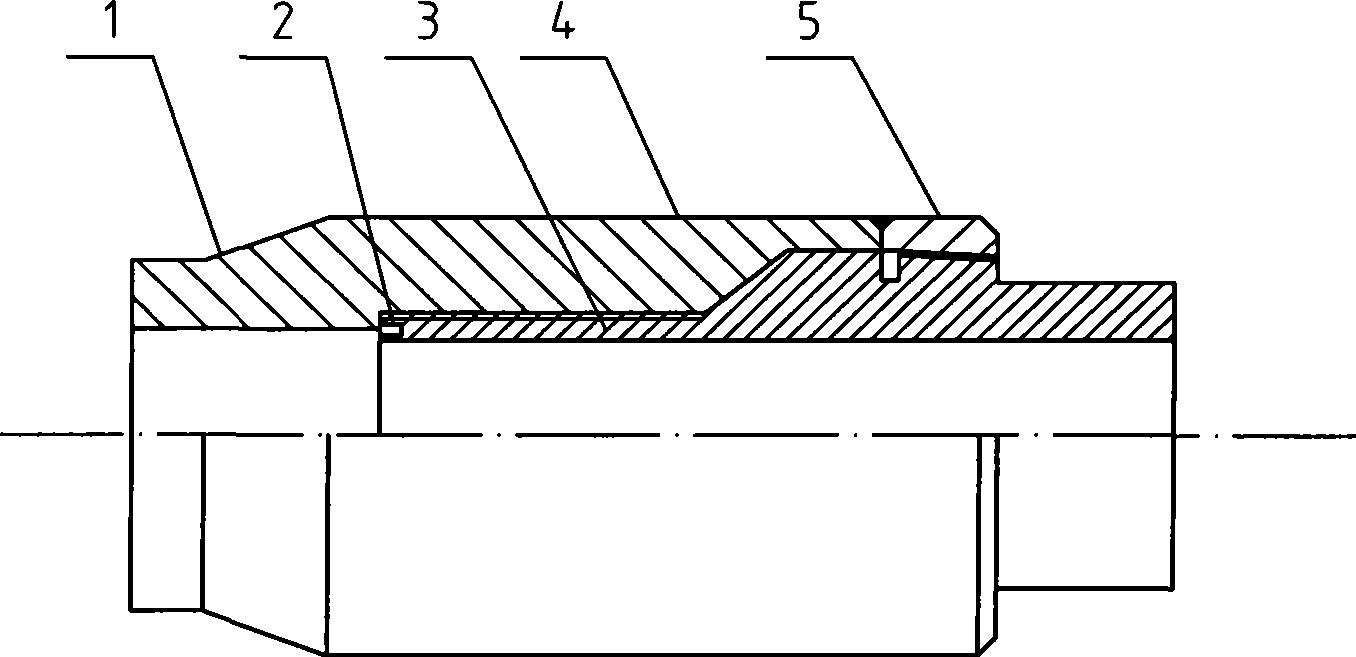

[0010] Depend on figure 1 The bimetallic joint shown includes a hollow cylindrical steel joint 3 and a hollow cylindrical aluminum joint 1 fixed outside the steel joint 3. The aluminum joint 1 is divided into front and rear aluminum joints 4 and 5, and the front part of the front aluminum joint 4 It is a tapered pipe and is connected with the steel joint 3 by sealing threads, and the front end surface of the front aluminum joint 4 is also provided with a sealing groove 2, the rear part of the front aluminum joint 4 is interference-fitted on the steel joint 3, and the rear aluminum joint 5 and the steel joint 3 are connected by tapered threads, and the front and rear aluminum joints 4 and 5 are welded. The part on the steel joint 3 that is in interference socket with the rear part of the front section 4 of the aluminum joint is trapezoidal.

[0011] The steel joint 3 and the aluminum joint 1 can enhance the sealing effect through the sealing thread and the interference socket....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com