Mould cavity numerical control machining spiral curve track planning method

A technology of curved trajectory and cavity, which is applied in the field of cavity CNC machining spiral curve trajectory planning, can solve the problems that the cutting process of narrow and long and complex cavity cannot be directly applied, and does not meet the requirements of high-speed machining of complex cavity, so as to achieve continuous tool trajectory, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are not intended to limit the present invention.

[0026] The cavity numerical control machining spiral curve track planning method proposed by the present invention is carried out according to the following steps:

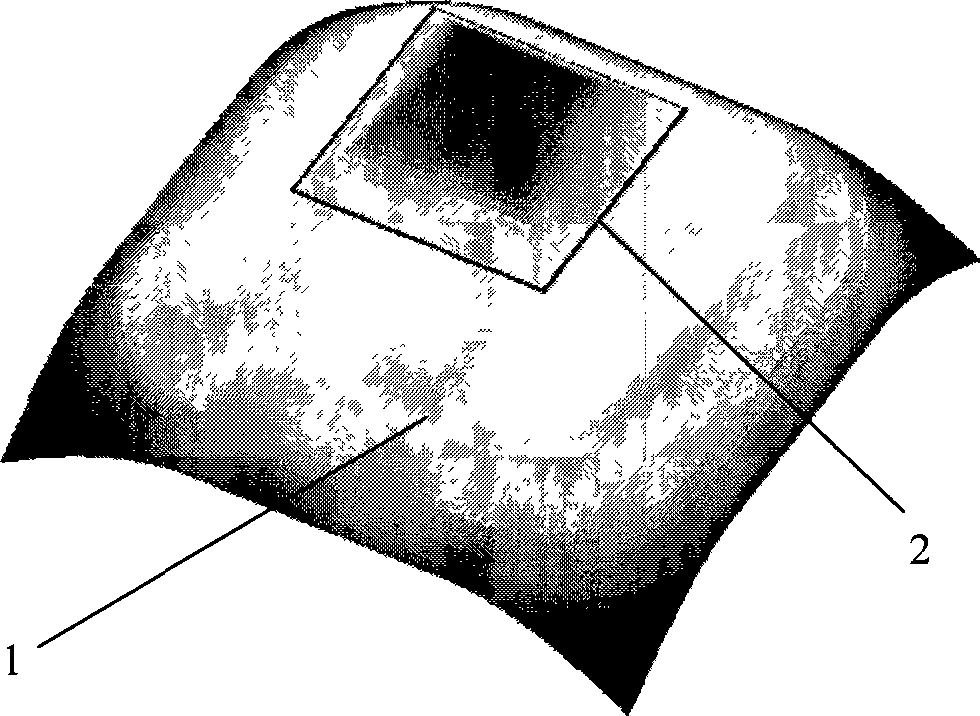

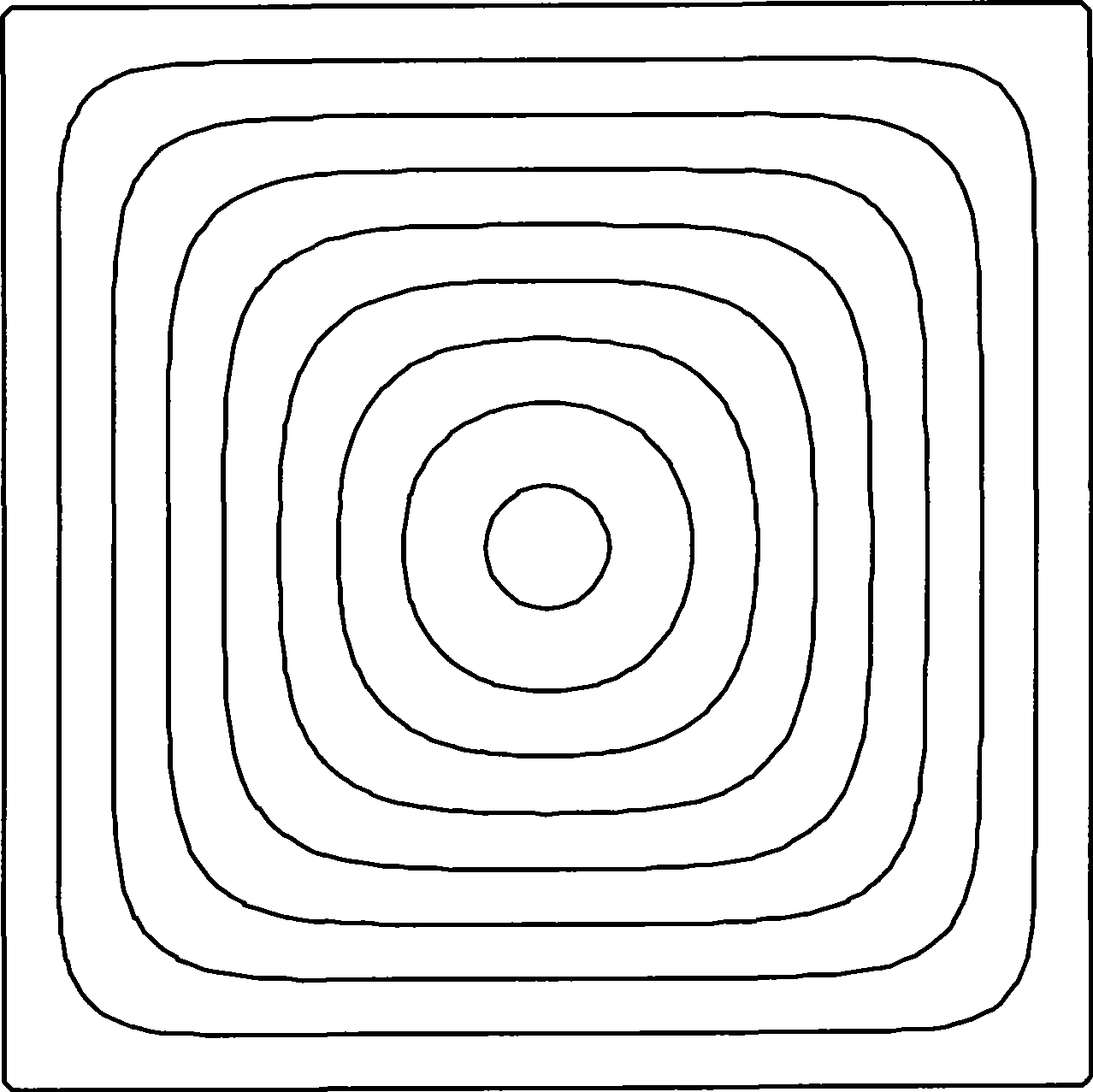

[0027] 1. First, the implicit description of the cavity boundary must be embedded into the level set function of the higher one-dimensional space. The zero level set of the level set function is the cavity boundary, and the level set function is initialized as a signed distance function. Such as figure 1 As shown in the rectangular cavity, embed it into a higher one-dimensional level set function, such as figure 2 As shown, among them, 1 is the level set function, 2 is the zero level set of the level set function, and the zero level set 2 is the rectangular cavity.

[0028] 2. Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com