Device for regeneration, temperature loading and/or thermal management, associated injection valve and method

一种喷射阀、热管理的技术,应用在排气处理装置的电控、消音装置、排气装置等方向,能够解决存在压力、波动、积碳等问题,达到压力范围增大、良好燃料喷雾准备的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

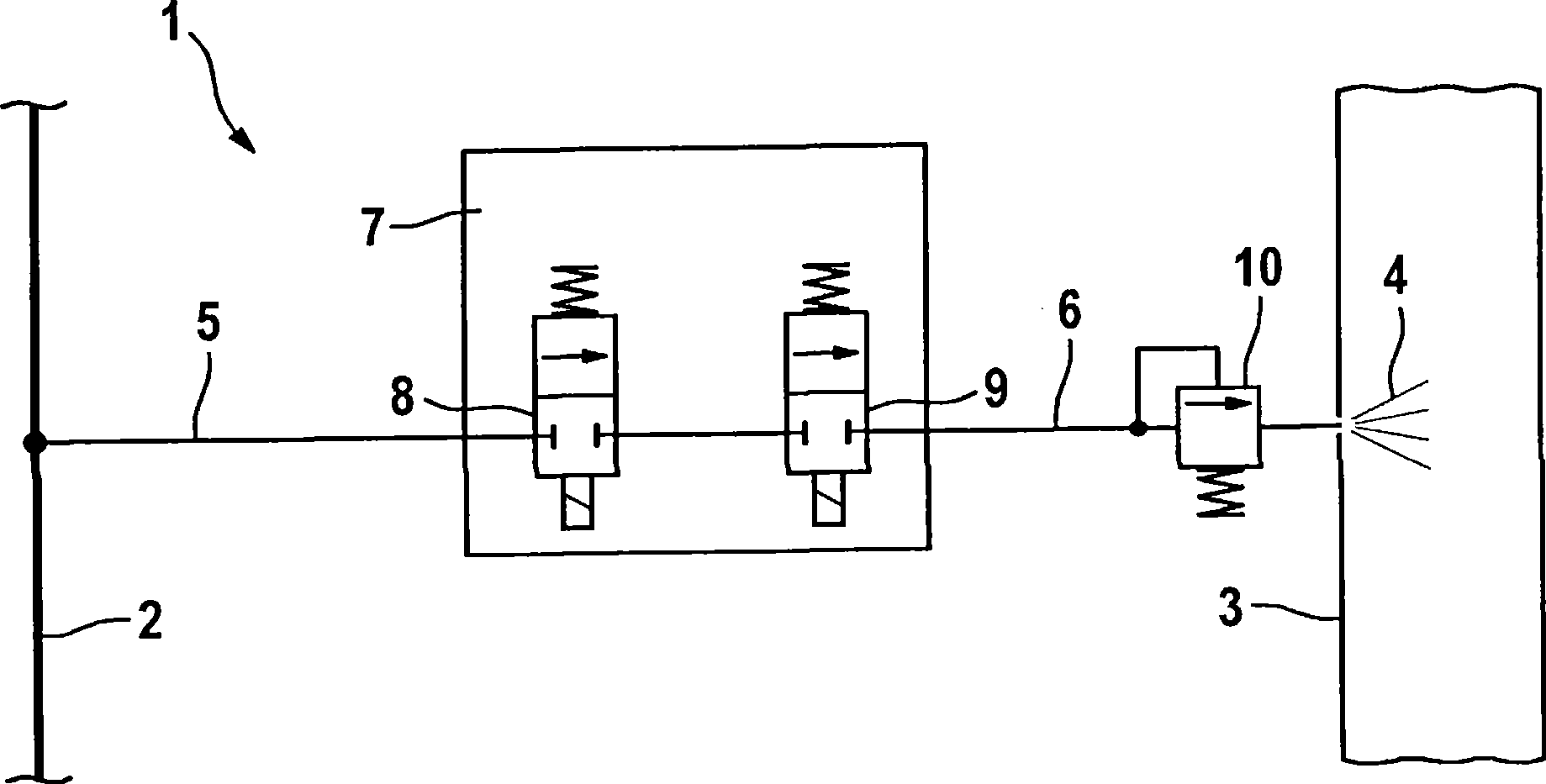

[0027] as from figure 1 As can be seen in , a device 1 for regeneration, temperature loading and / or thermal management of components of an internal combustion engine associated with the exhaust system comprises an injection valve 10, a safety valve connected upstream of the injection valve 10 and a Metering valve 9, the injection valve injects fuel 4 into the exhaust pipe 3 of the exhaust system according to the pressure of the input fuel, the safety valve can interrupt the fuel input, the metering valve is arranged between the safety valve 8 and the injection valve 10 time and determine the fuel quantity for injector 10 . The component associated with the exhaust system can be, for example, a particulate filter, in particular a diesel particulate filter, or a NOx accumulator.

[0028] The safety valve 8 , the metering valve 9 and the injection valve 10 are each designed as spring-loaded valves, wherein the safety valve 8 and the metering valve 9 are arranged in a structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com