Automotive lamp module and lighting unit with LED lighting element

A technology of LED lighting and lighting units, which is applied in the direction of vehicle lighting systems, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of increased working temperature, reduced lighting output, and reduced working life, and achieves a simple and efficient structure. The effect of a compact, compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

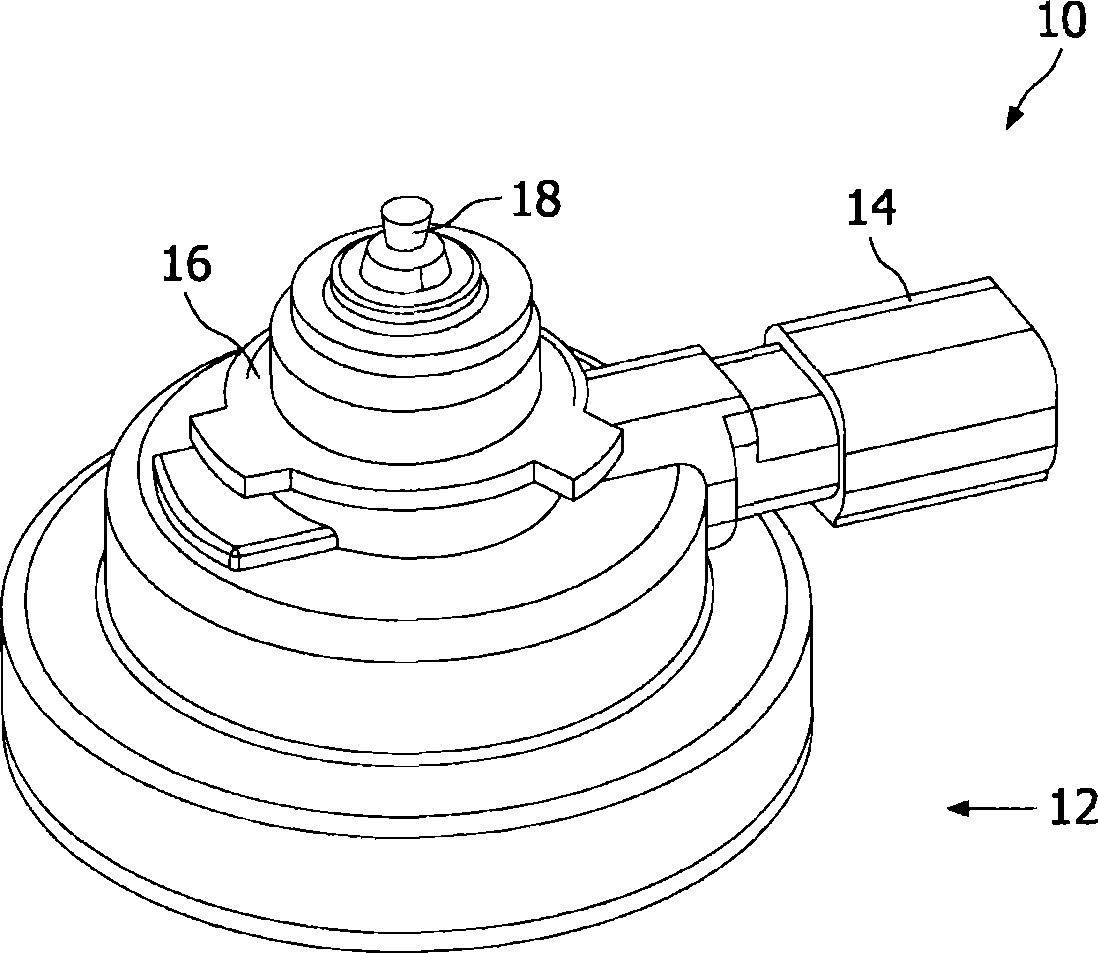

[0033] figure 1 A lamp module 10 is shown. The lamp module 10 includes a module body 12 with a protruding plug housing 14, a locking portion 16 for locking the lamp module 10 within the reflector, and an LED lighting element 18.

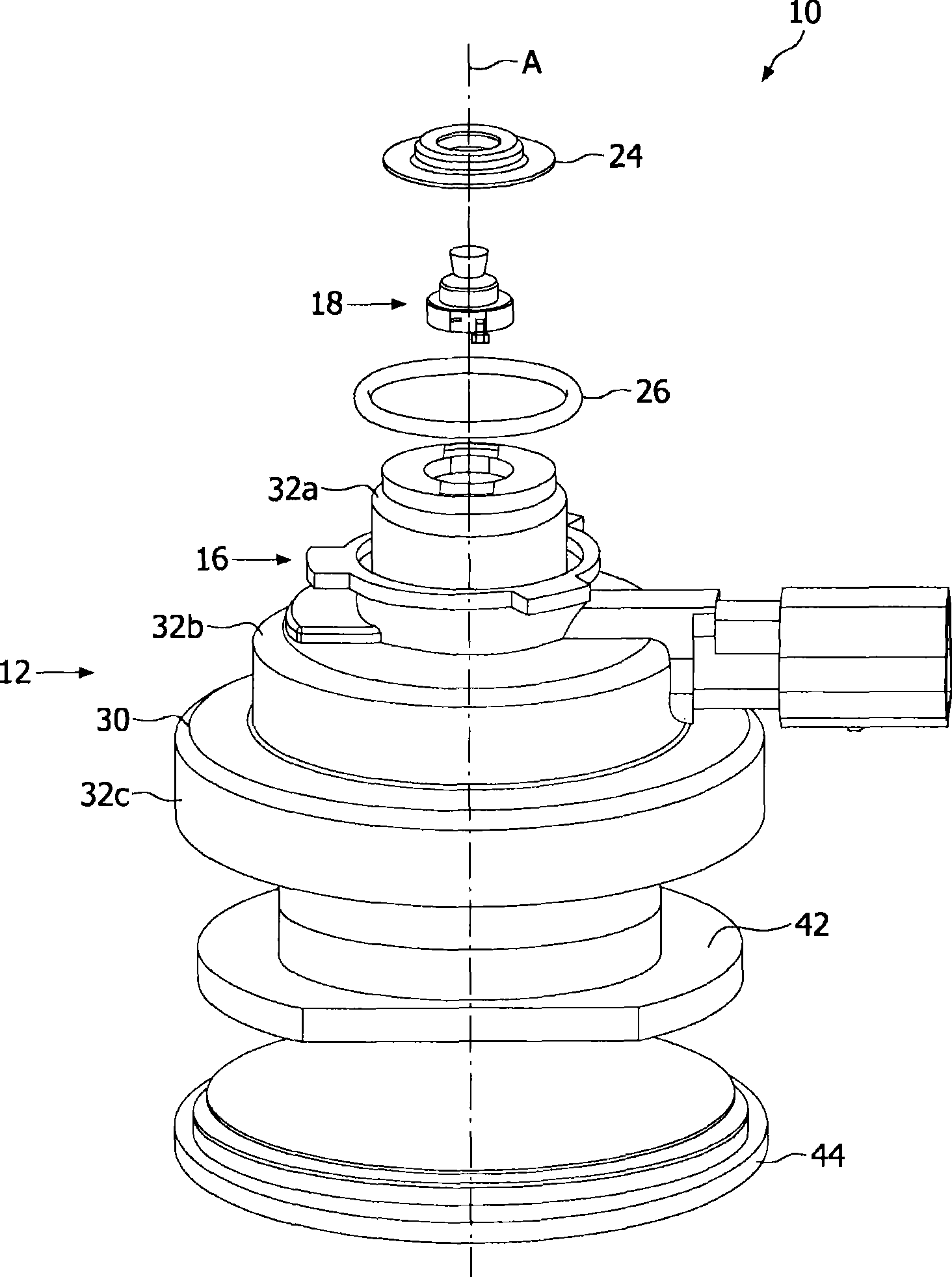

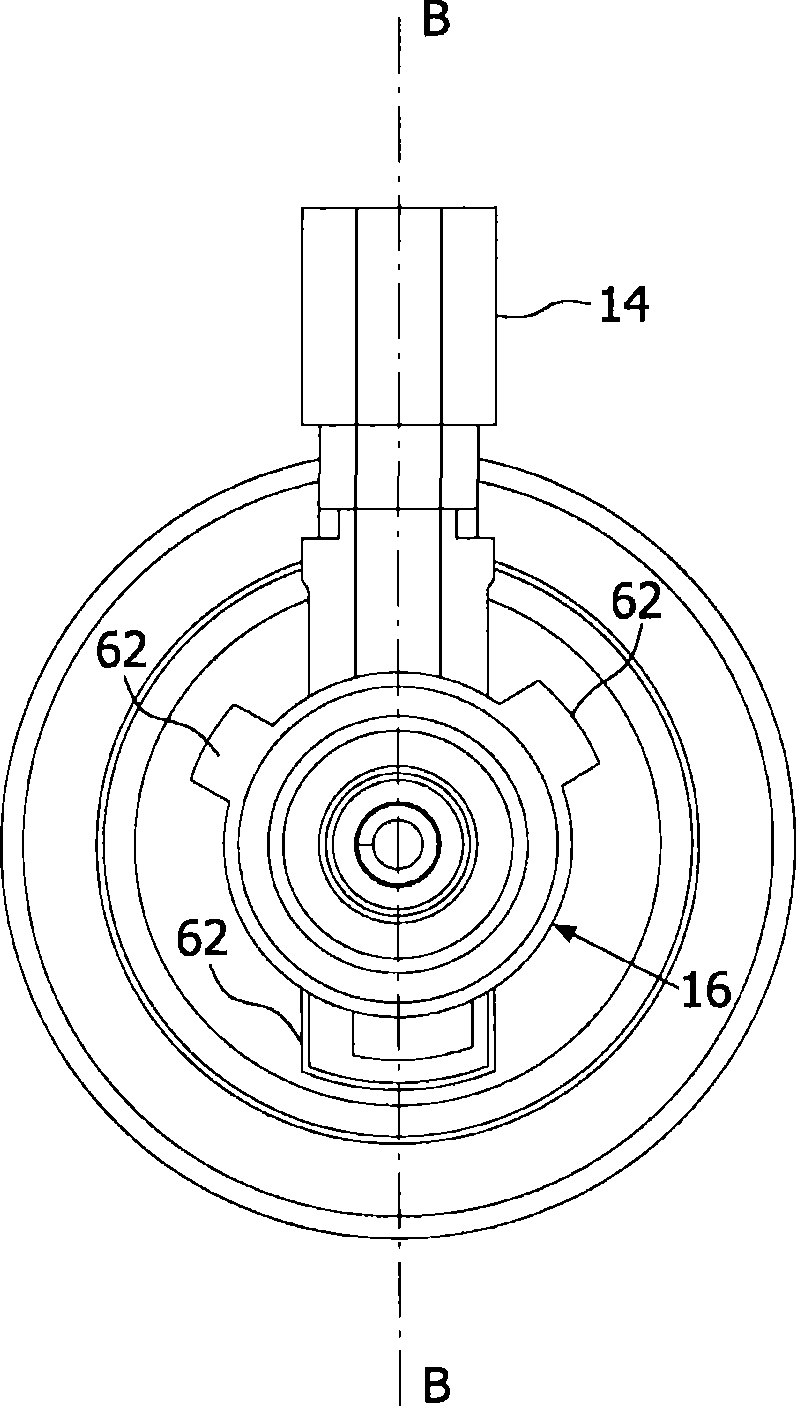

[0034] as in figure 2 with Figure 4 As shown in the exploded view in , the LED modules 10 are assembled in a stacked manner. The module body 12 has a substantially circular cross-section, thus defining a central axis A, which will be described in detail below. The top of the main body 12 is also centered on the axis A, and the LED lighting element 18 is located on the top of the main body 12 . The LED element 18 includes an LED 20 for generating light and a side emitter reflector 22 (see Figure 5 ), the side emitting reflector 22 is used to reflect the generated light so as to guide the generated light in a radial direction with the central axis A, which will be performed in the positioning of the lamp module 10 in the reflector It is clear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com