Horizontal-push type self-discharging vehicle

A dump truck and self-unloading technology, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, and vehicles used for freight, can solve the problems of inappropriateness, etc., and achieve the effects of not easy to wear, small gap and sliding friction resistance, and accurate sliding positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

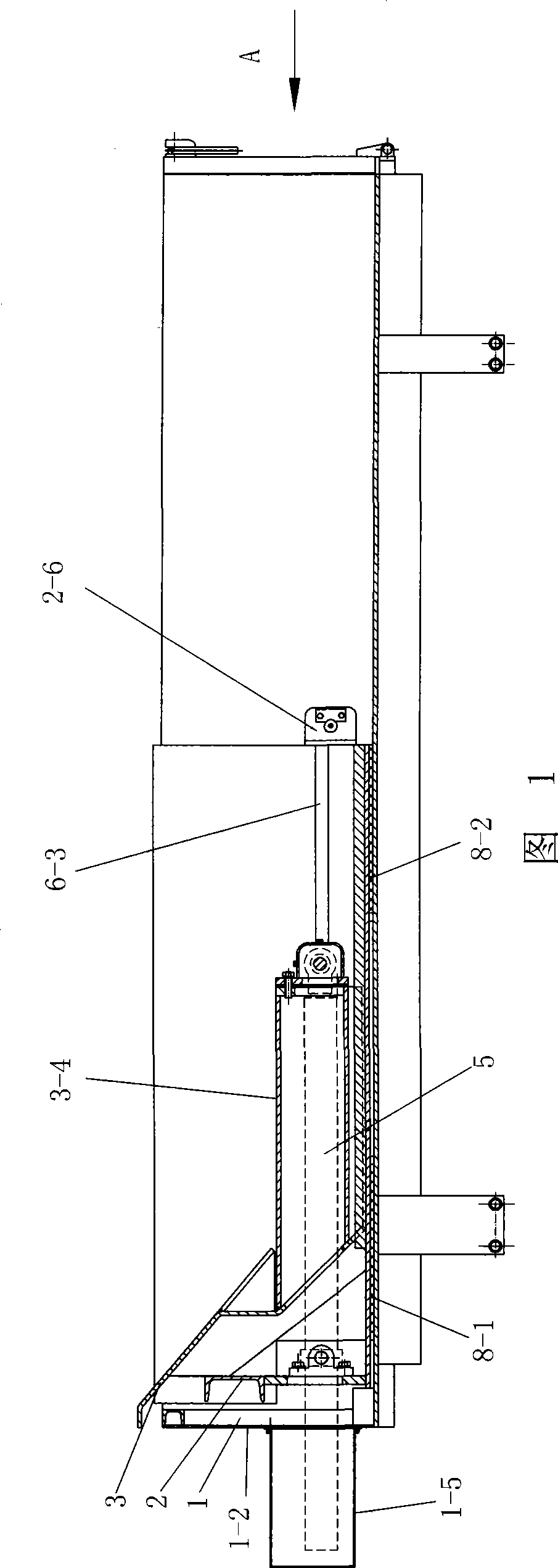

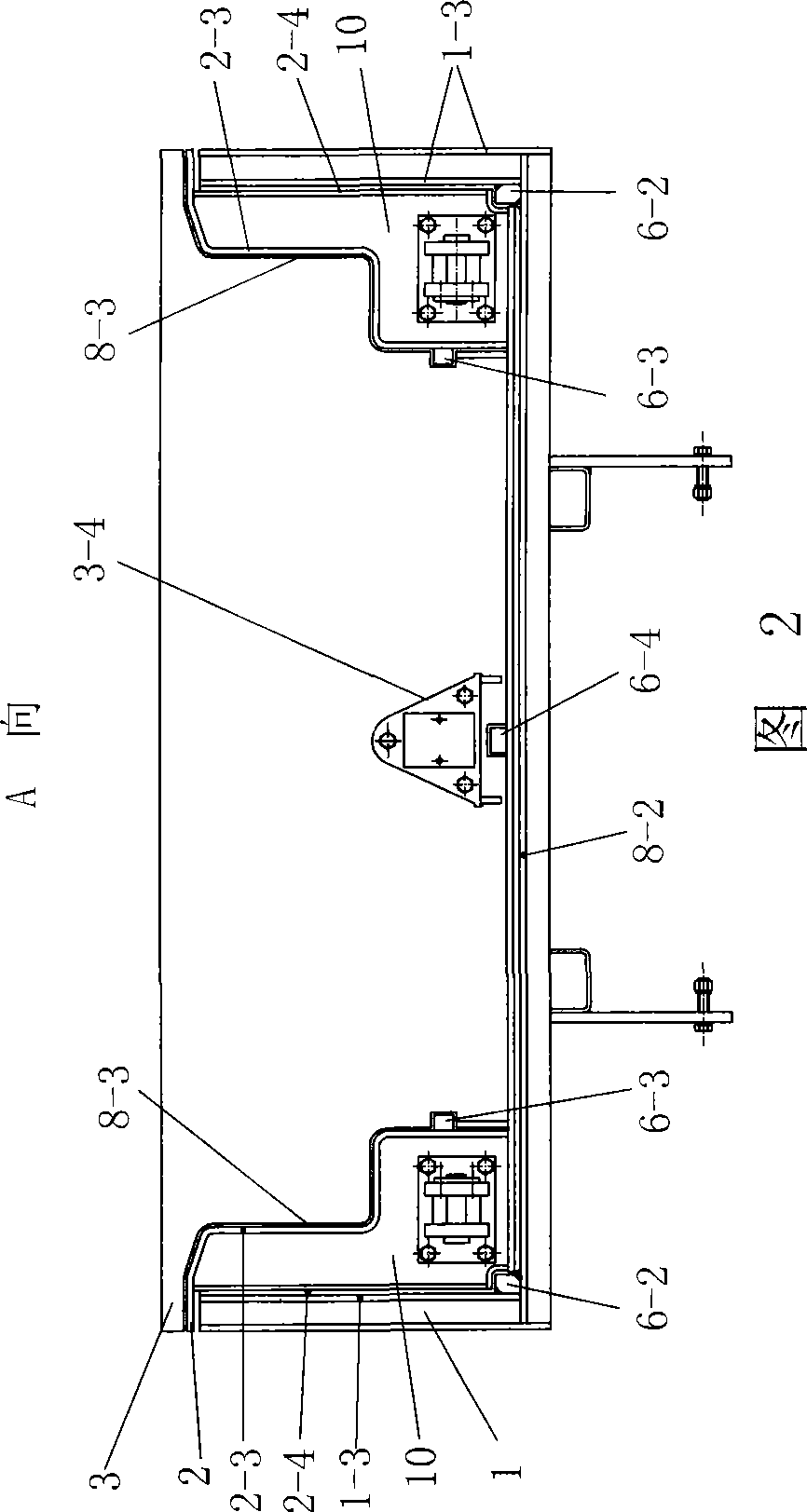

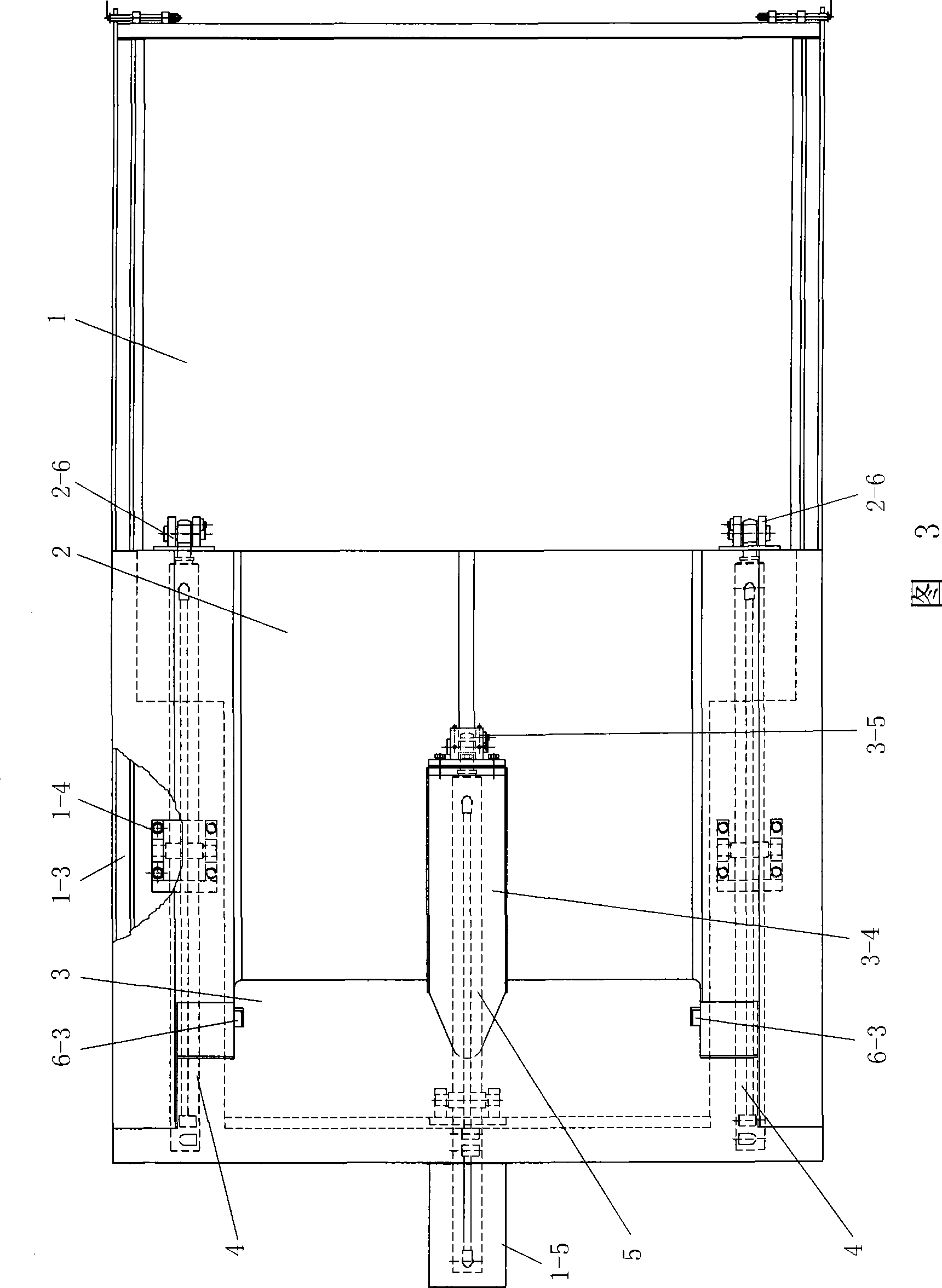

[0028] See Figures 1 to 3, the present embodiment has a self-unloading mechanism and a self-unloading hydraulic system. The self-unloading mechanism includes a compartment 1, a push compartment 2 that is in the compartment 1 and is shorter than the compartment, and a push compartment 2 that is in the push compartment 2 and is shorter than the compartment. The push piece 3 of the push box. The self-unloading hydraulic system includes left and right hydraulic cylinders 4 arranged in parallel between the carriage 1 and the push box 2, an intermediate hydraulic cylinder arranged between the push box 2 and the push piece 3 and parallel to the left and right hydraulic cylinders 4 5.

[0029] See Figure 4 to Figure 5 , the compartment 1 has a floor 1-1, a front compartment panel 1-2, and left and right compartment panels 1-3. For alleviating the weight of the compartment, the base plate 1-1 is provided with weight reduction and leakage holes 1-1-1, and the left and right compartme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com