Method for improving crude fiber and fine fiber blended strength

A fine fiber and thick fiber technology, applied in the field of spinning, can solve problems such as difficult cohesion, poor strength, and low cohesion of blended yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

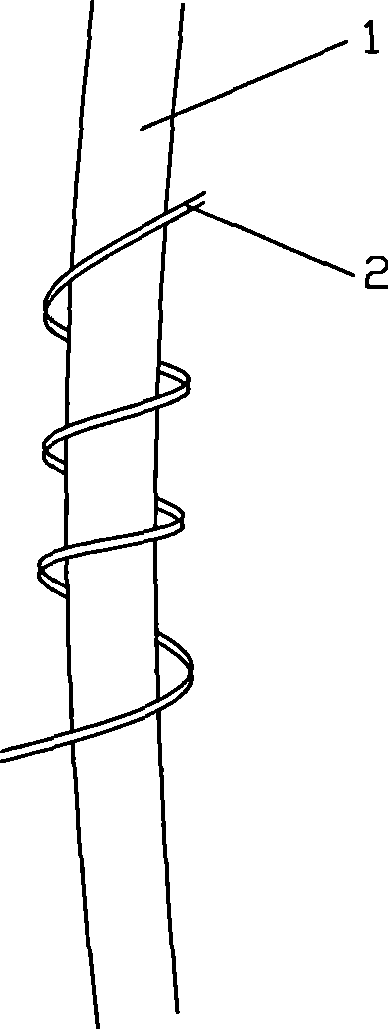

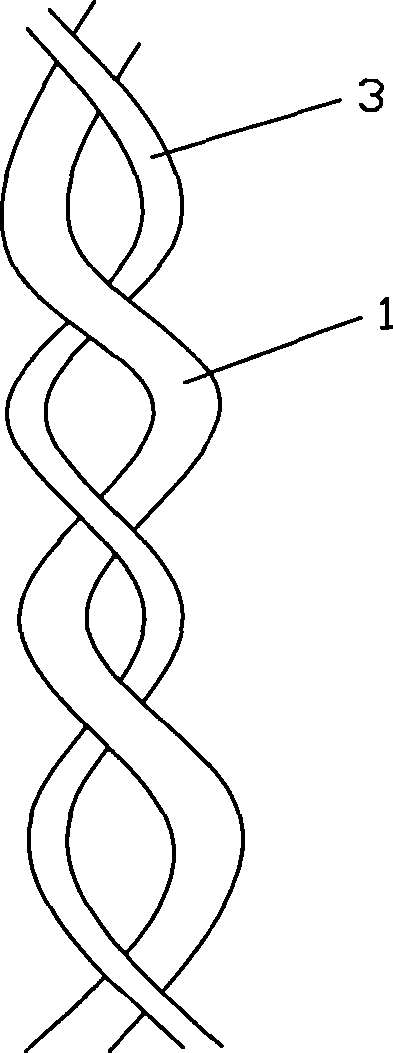

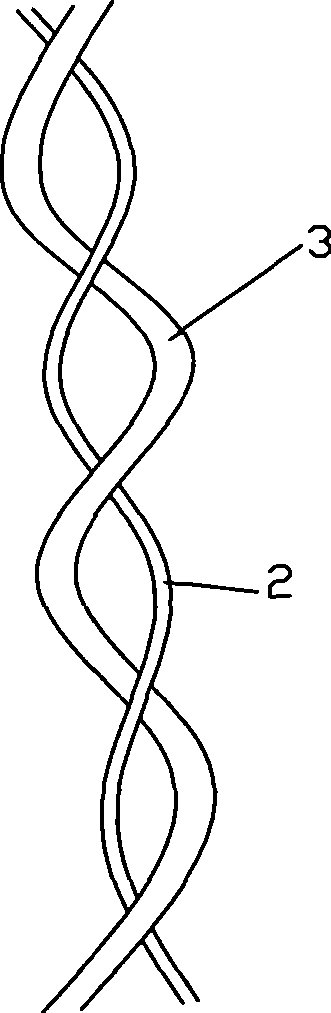

[0027] Increase length at 27~33 millimeters, the flax fiber that fineness is about 1200 (Nm) carries out fiber mixing together as intermediate fiber with jute fiber and cotton fiber. The fineness metric count (Nm) of the flax fiber is 2.4~3 times of the fineness metric count (Nm) of the jute fiber, and the fineness metric count (Nm) of the cotton fiber is 2.4~3 times of the flax fiber fineness metric count (Nm). About 5 times that of fiber, according to figure 2 and image 3 As shown, at this time, because the fineness difference between flax fiber, jute fiber and cotton fiber is not large, it can be entangled with jute fiber and cotton fiber in blending. The breaking strength of jute / cotton / flax blended 12 counts (s) yarns of different blending ratios is shown in the table below:

[0028] Table 2 Breaking strength of jute / cotton / flax blended yarn with 12 counts (s)

[0029] Proportion (wt%) Breaking strength (cN) 20 / 65 / 15 580.93 25 / 50 / 25 629.05 3...

Embodiment 2

[0033] In order to enhance the breaking strength of jute and cotton fiber blended yarn, it is also possible to add polyester fibers with a length of 27 to 33 mm and a fineness of 2000 to 4500 (Nm) into the jute and cotton fibers for fiber mixing. The breaking strength of 12 yarns of blended jute / cotton / polyester fiber blended in percentage by weight is shown in the table below.

[0034] Table 3 Breaking strength of jute / cotton / polyester blended yarn with 12 counts (s)

[0035] Proportion (wt%) Breaking strength (cN) 20 / 65 / 15 592.87 25 / 50 / 25 647.56 30 / 50 / 20 618.93 30 / 40 / 30 655.79 40 / 45 / 15 587.65

[0036] 45 / 50 / 5 545.98 50 / 28 / 22 590.45 60 / 30 / 10 535.58 70 / 20 / 10 520.67 80 / 15 / 5 496.05

[0037] As can be seen from Table 3, except that the breaking strength of the yarn of a kind of jute / cotton / polyester blend ratio of 80 / 15 / 5 (wt%) does not reach 520 (cN), all the other have exceeded 520 (cN). The breaking s...

Embodiment 3

[0039] Also can add length about 31-35 millimeter in jute and cotton fiber in order to strengthen the breaking strength of jute and cotton fiber blended yarn, and the ramie fiber that fineness is about 1200 (Nm) carries out fiber mixing. The breaking strength of the 12-count yarns of the three fiber blends mixed according to different weight percentages are shown in the table below.

[0040] Table 4 Breaking strength of jute / cotton / ramie blended yarn with 12 counts (s)

[0041] Proportion (wt%) Breaking strength (cN) 20 / 65 / 15 589.76 25 / 50 / 25 638.03 30 / 50 / 20 604.58 30 / 40 / 30 623.45 40 / 45 / 15 588.56 45 / 50 / 5 534.79 50 / 28 / 22 579.08

[0042] 60 / 30 / 10 536.98 70 / 20 / 10 530.28 80 / 15 / 5 500.69

[0043] As can be seen from Table 4, except that the breaking strength of the yarn of a kind of jute / cotton / ramie blend ratio of 80 / 15 / 5 (wt%) does not reach 520 (cN), all the others have exceeded 520 (cN). The breaking str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com