Light beam shaper by refractometry for two-dimension laminate light source

A technology of beam shaping and refraction, applied in laser devices, semiconductor laser devices, optics, etc., can solve problems such as difficult fiber coupling output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

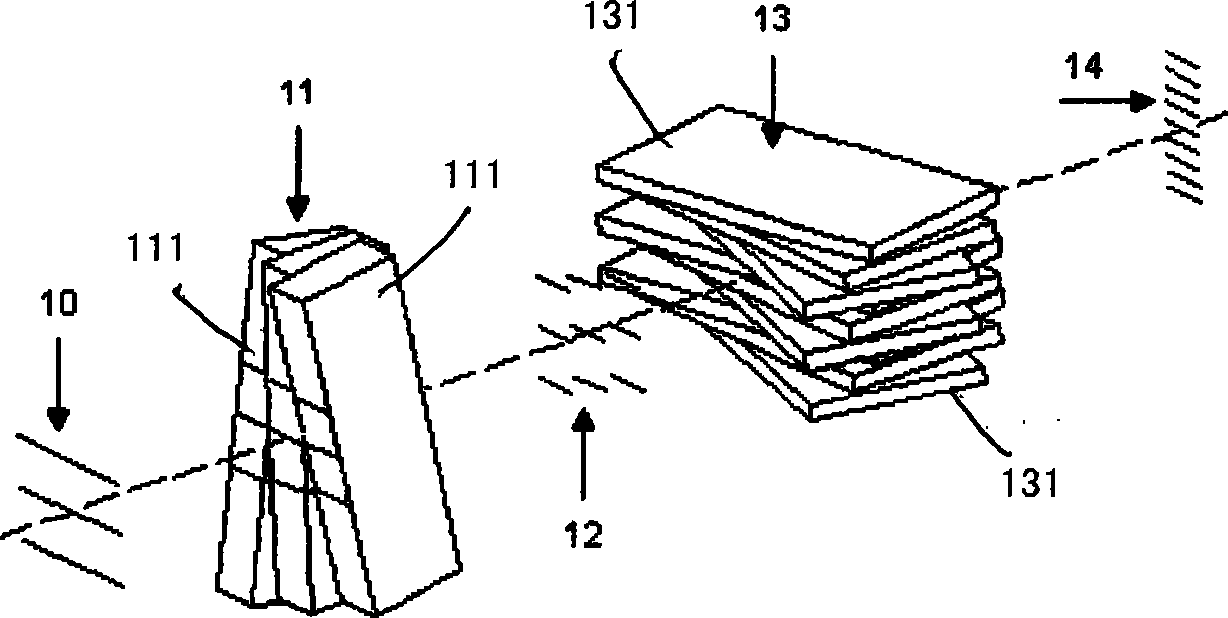

[0028] see Figure 1 to Figure 3 As shown, the present invention is a refraction beam shaper for a two-dimensional stacked light source, which is characterized in that it includes:

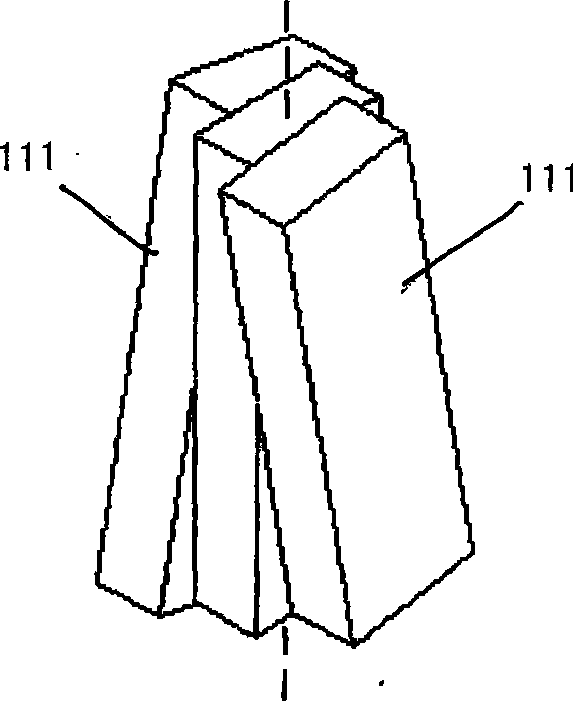

[0029] A first parallel flat mirror stack 11, the first parallel flat mirror stack 11 is formed by stacking a plurality of parallel flat mirrors 111, and each parallel flat mirror 111 of the first parallel flat mirror stack 11 is arranged in an X shape according to a central axis The fans are closely arranged;

[0030] The height of the first parallel flat mirror stack 11 is greater than the overall height of the shaped light source, and the width is greater than the overall width of the shaped light source;

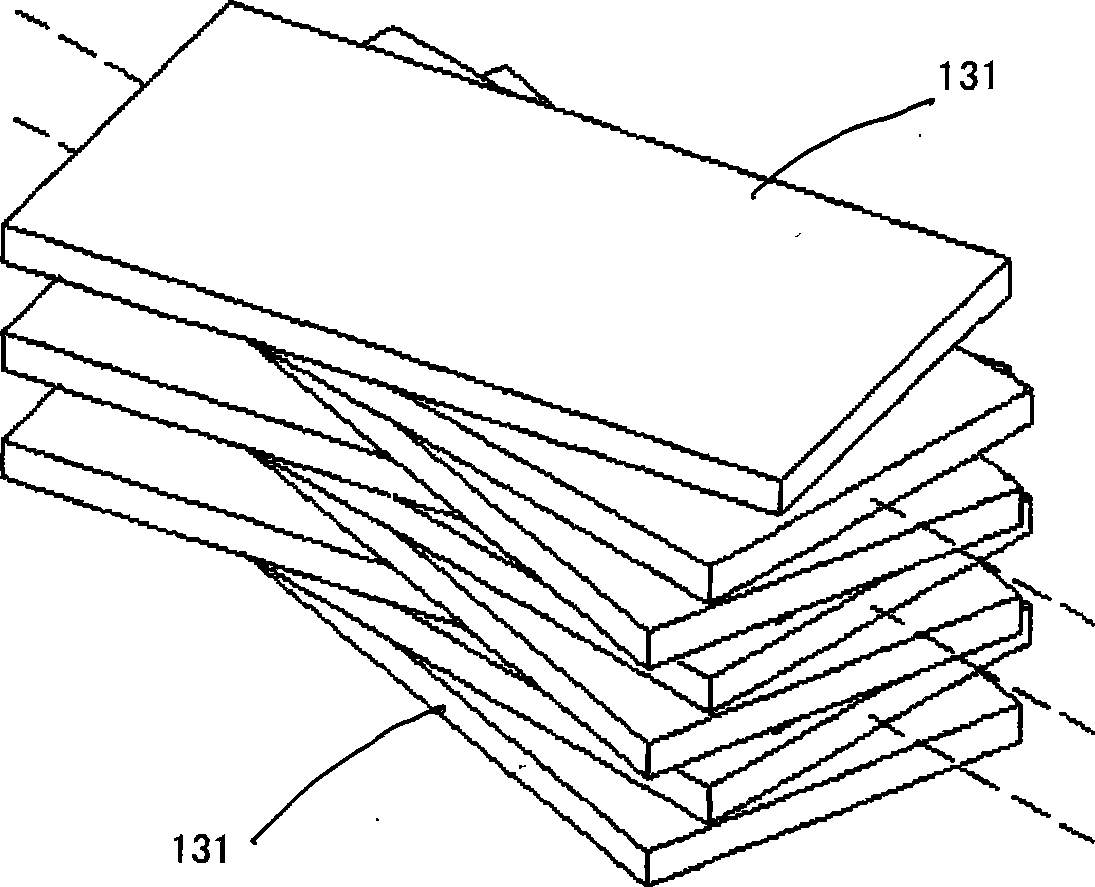

[0031] A second parallel flat mirror stack 13, the second parallel flat mirror stack 13 is formed by stacking a plurality of parallel flat mirrors 131, the second parallel flat mirror stack 13 takes the number of parallel flat mirror stacks 11 as a period, and every A plurality of parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com