Production method for floating gate of flash memory in grating

A manufacturing method and floating gate technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as unfavorable process reliability, incomplete erasure efficiency, and difficulty in cutting-edge optimization, so as to reduce erasure Effects of invalidation, optimization of fluctuations, and reduction of intra-chip discontinuities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

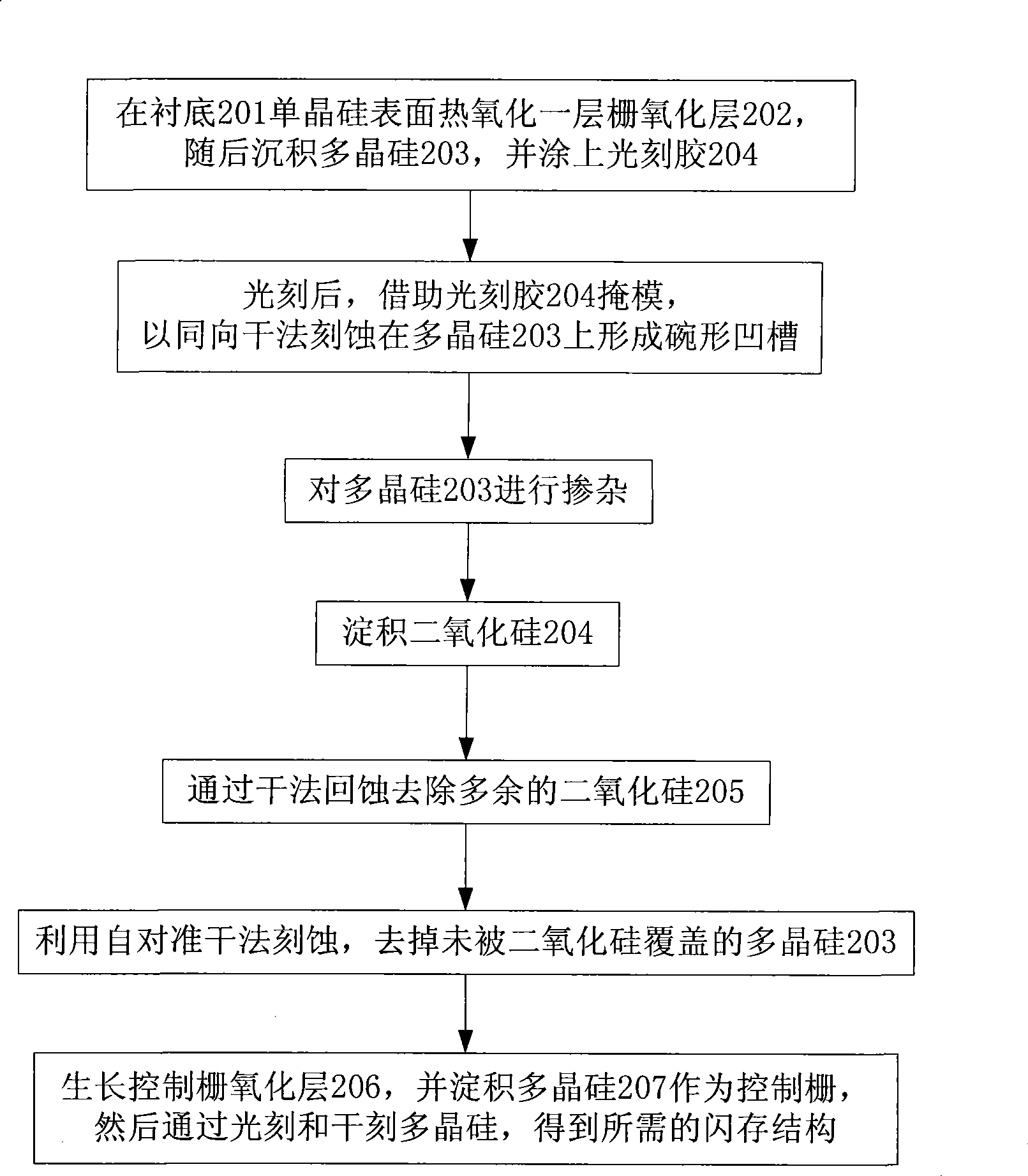

[0015] In one embodiment, such as figure 1 and Figures 2a-2g As shown, the method for manufacturing the floating gate of the split-gate flash memory of the present invention includes the following steps:

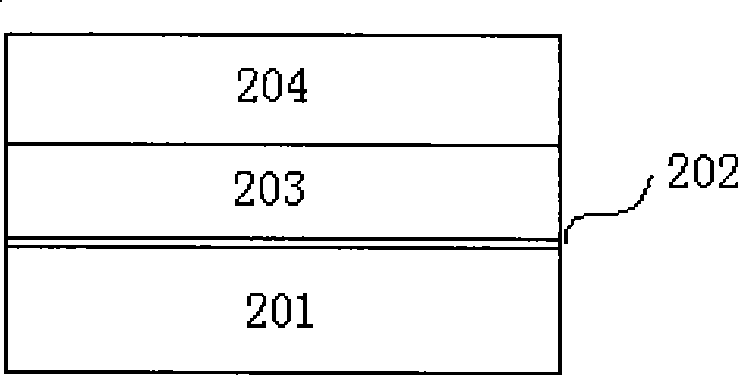

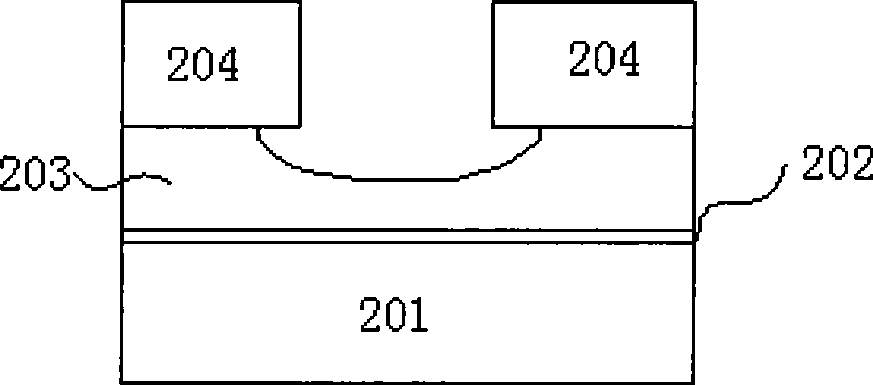

[0016] (1) Split-gate flash memory has a structure different from ordinary flash memory. In order to ensure that hot electrons can be written more effectively in split-gate flash memory, the P-type well and source-drain of split-gate flash memory are completed on the silicon substrate 201. After ion implantation and other processes, it is necessary to thermally oxidize a layer on the surface of the silicon substrate 201 with a thickness of 75-105 The thin film 202 in the range is used as the gate oxide layer 202 of the floating gate, and then a layer with a thickness of 3500-4500 is deposited on the gate oxide layer 202 range of polysilicon 203, and then coated with a layer thickness of about 10,000 photoresist 204 to carry out photoetching to the polysilicon 203, at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com