Flash memory floating gate manufacturing method

A manufacturing method and floating gate technology, which is applied in the field of flash memory manufacturing, can solve problems such as difficult cutting-edge optimization, low production efficiency, and incomplete erasing, and achieve the effects of reducing erasure failure, improving production efficiency, and being easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

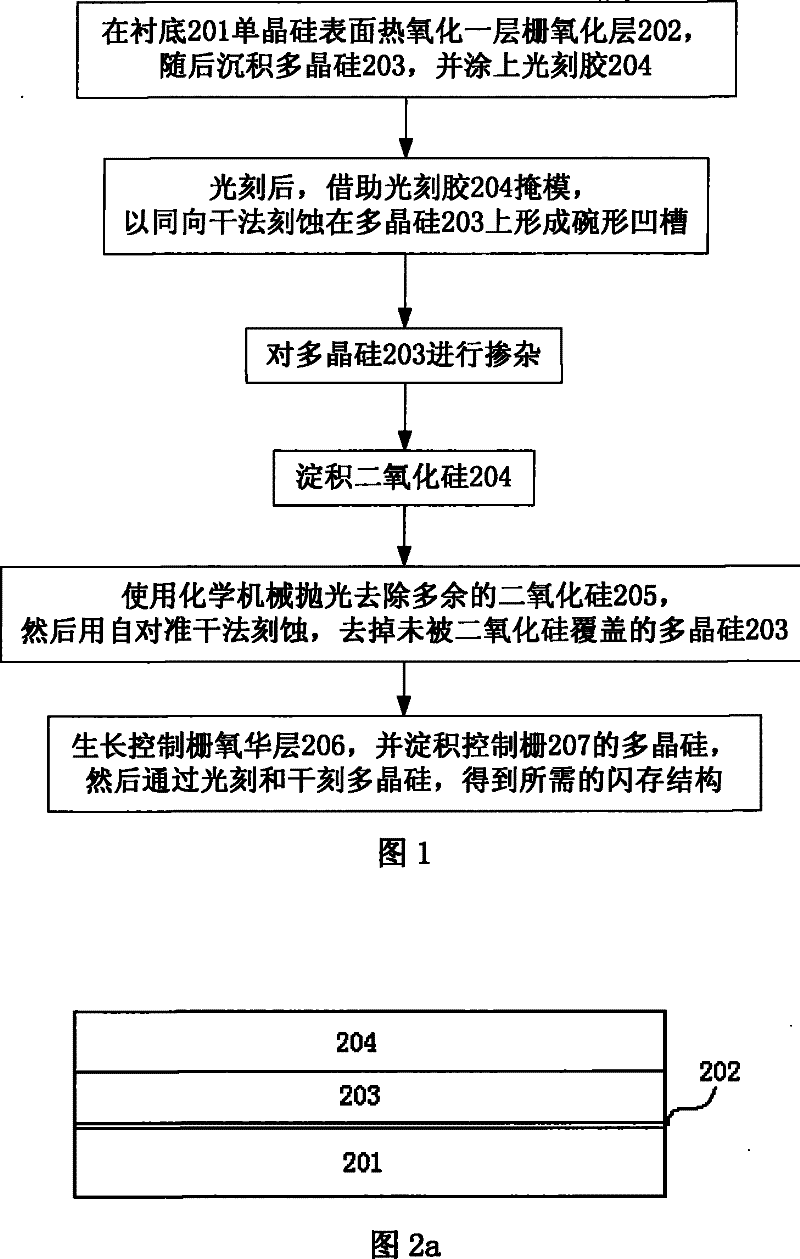

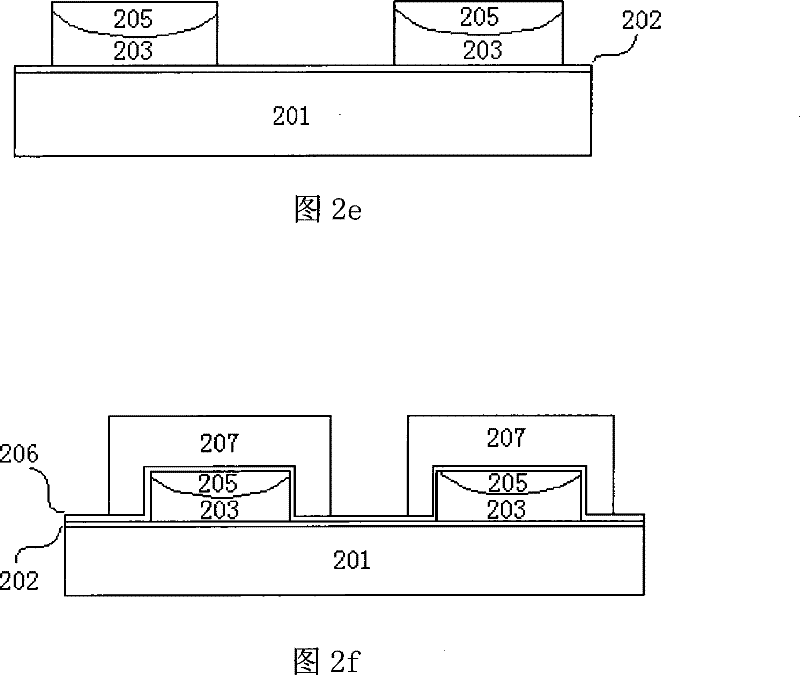

[0014] pass below figure 1 and Fig. 2, the flash memory floating gate manufacturing method of the present invention is described in detail, the method mainly includes the following steps:

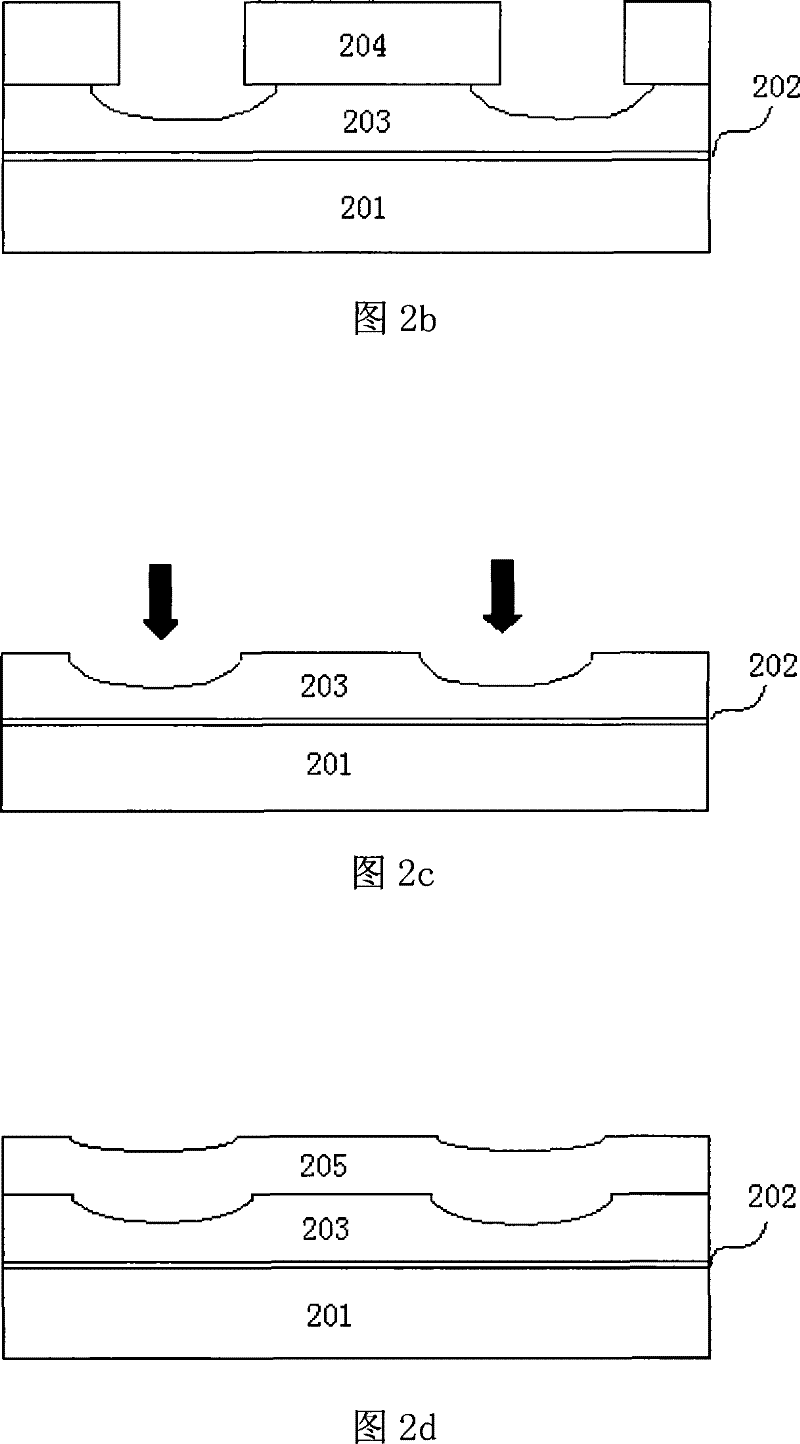

[0015] (1) The thickness of a layer of thermal oxidation on the surface of substrate 201 single crystal silicon is The thin film 202 within the range is used as the gate oxide layer 202 of the floating gate, and then a layer with a thickness of polysilicon 203 within the range, and then coated with photoresist 204 to perform photoetching on the polysilicon 203, specifically as Figure 2a shown.

[0016] (2) Utilize known photolithography technique to carry out photoetching to described polysilicon 203, then with the help of photoresist 204 mask, form the bowl-shaped groove ( That is, the flash memory cell area), specifically as Figure 2b shown.

[0017] (3) if Figure 2c As shown, the polysilicon 203 is doped with phosphorus (P) ions to reduce its resistivity.

[0018] (4) Deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com