Hydrogen storage system for fuel cell vehicle

A fuel cell stack and hydrogen storage technology, applied in the field of hydrogen storage systems, can solve problems such as low weight storage density, low hydrogen release temperature, and inability to meet the hydrogen supply conditions of fuel cell stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

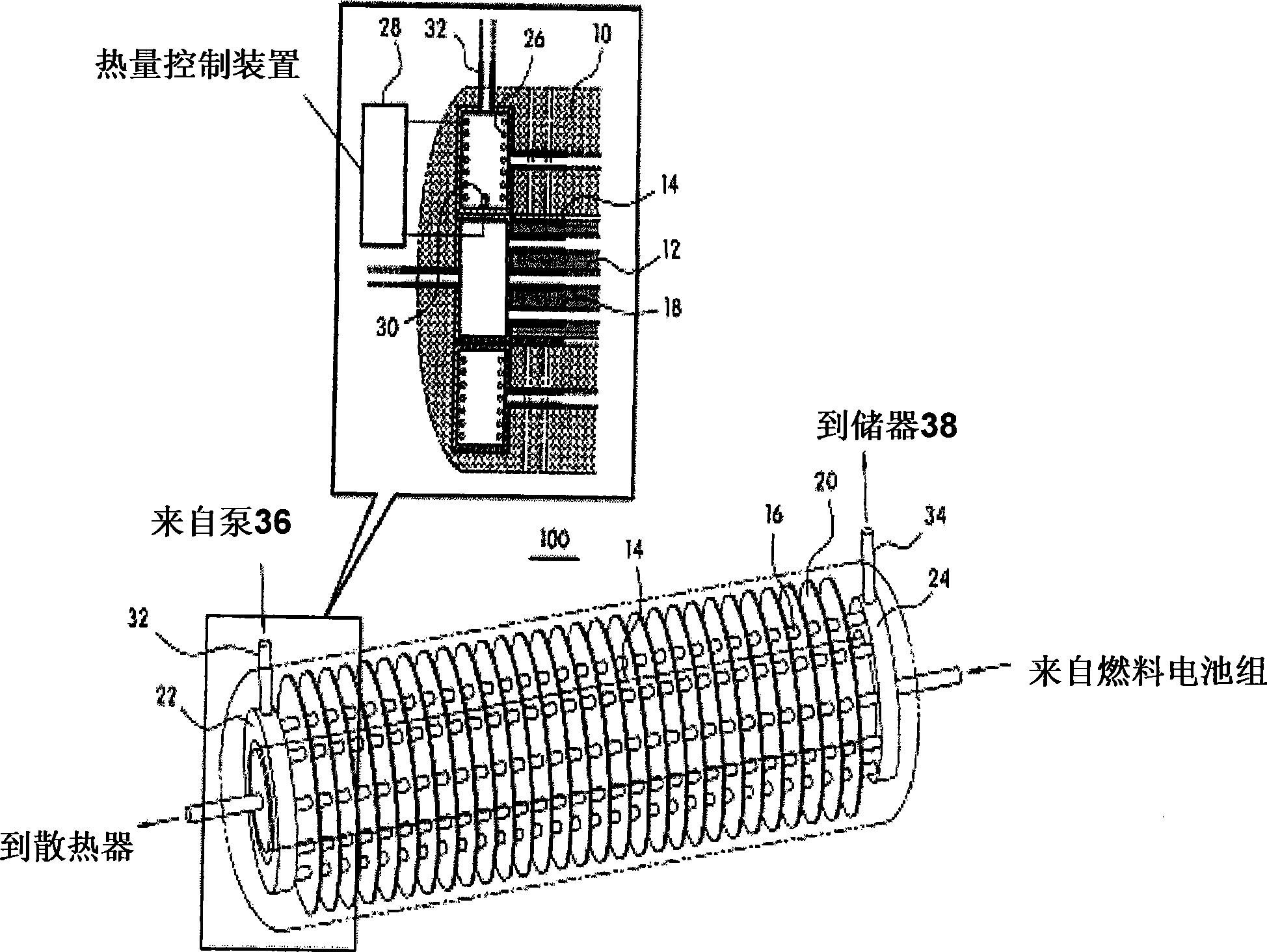

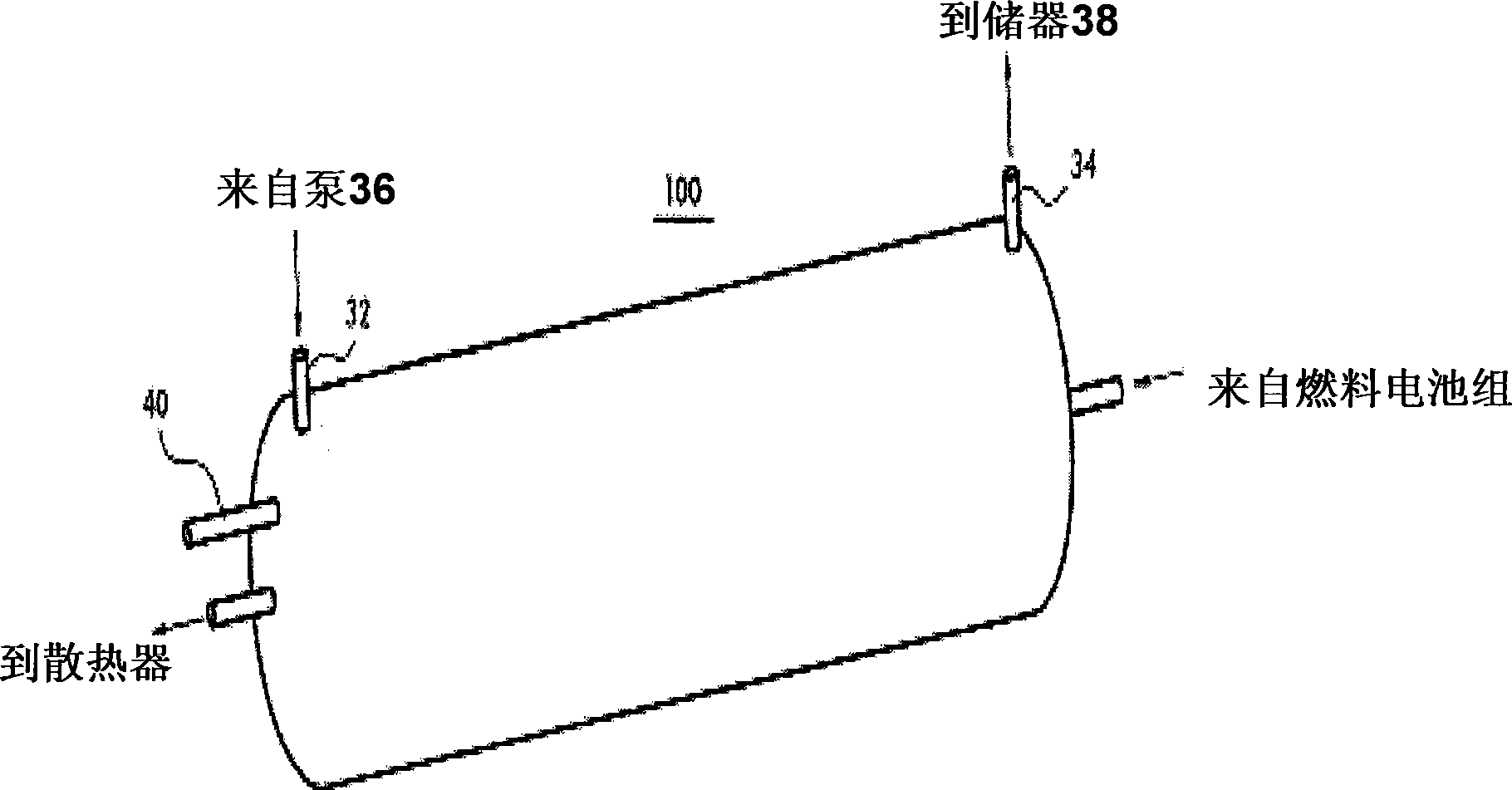

[0059] Reference will now be made in detail to preferred embodiments of the present invention, examples of which are illustrated in the drawings hereinafter appended, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

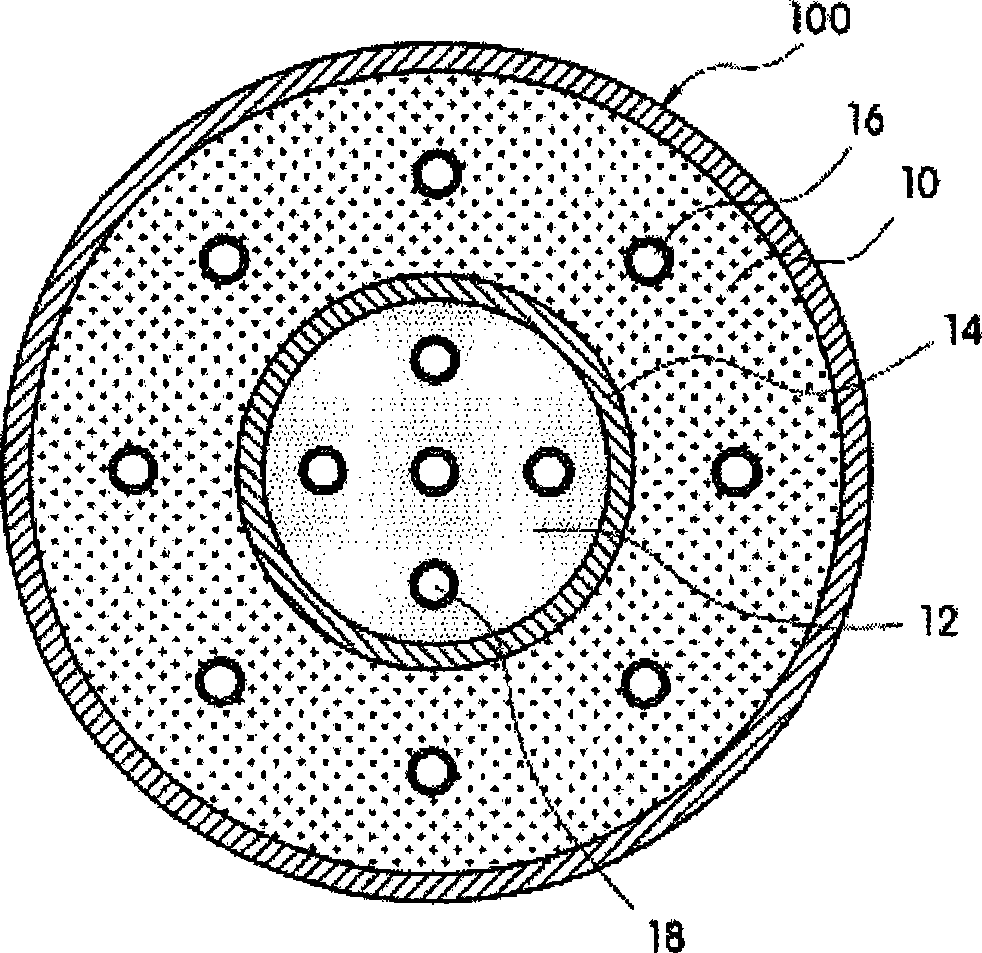

[0060] figure 1 is a sectional view showing main parts of a hydrogen storage tank of a hydrogen storage system for a fuel cell vehicle according to a preferred embodiment of the present invention.

[0061] Such as figure 1 As shown in , the first storage alloy powder 10 that can release hydrogen at a relatively high temperature is filled in the external space V1 of the cylindrical MH hydrogen storage tank 100, and can release hydrogen and The second storage alloy powder 12 that can release hydrogen at low temperature is filled into its internal space V2.

[0062] Specifically, the first storage alloy powder 10 is filled outside the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com