Middle joint of high voltage electric cable for connecting composite optical fiber and connecting method

A high-voltage cable and composite optical fiber technology, which is applied in the direction of cable joints, optical waveguide coupling, etc., can solve problems such as influence, fiber fusion point loss, unreliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

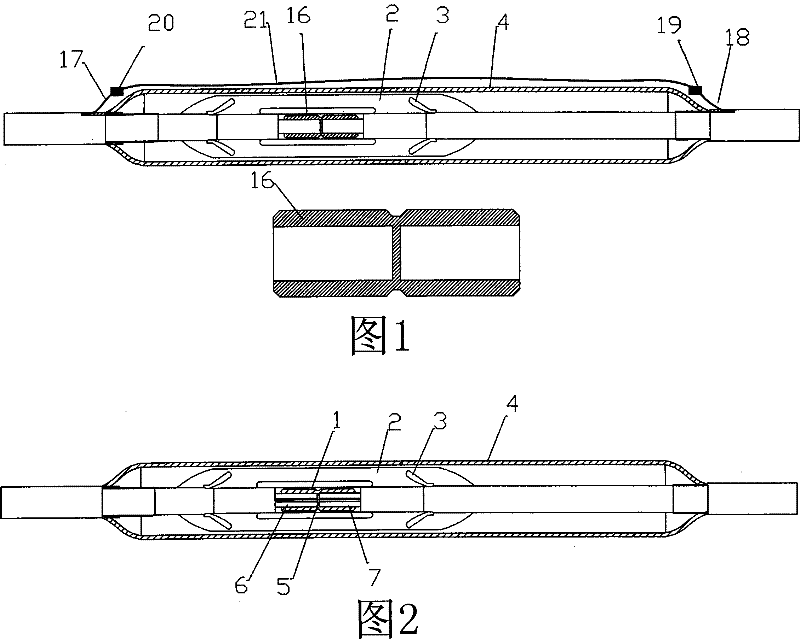

Embodiment 1

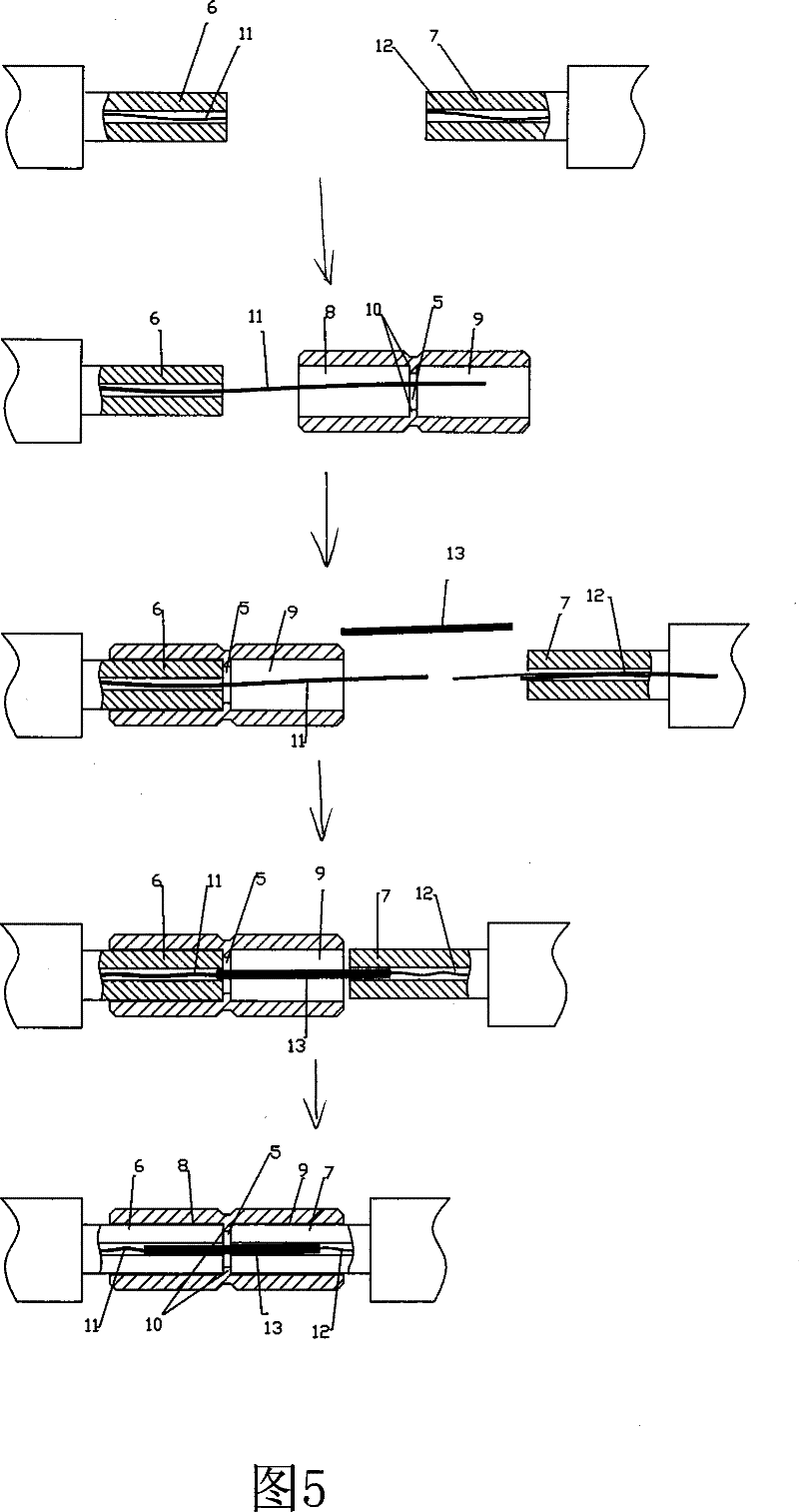

[0048] Figure 5 It is a schematic diagram of Embodiment 1 of the method for connecting a high-voltage cable of a composite optical fiber with an intermediate joint of the present invention. This figure has described a kind of installation method utilizing the middle joint of the high-voltage cable that connects composite optical fiber, and this method comprises the following steps:

[0049] The first step is to make cable ends respectively for the first cable and the second cable to be connected, and strip off the first center conductor 6 and the second center conductor 7 therein;

[0050] The second step is to pull out the first optical cable 11 from the first center conductor 6 of the first cable, pass the first optical cable 11 through the first chamber 8, the channel 5 and the second chamber 9 in turn, and from the second chamber 9 to wear a certain length;

[0051] The third step is to insert the first central conductor 6 into the first cavity 8 and abut against the pa...

Embodiment 2

[0055] Figure 6 It is a schematic diagram of Embodiment 2 of the method for connecting the high-voltage cable of the composite optical fiber with the intermediate joint of the present invention. This figure has described a kind of installation method utilizing the middle joint of the high-voltage cable that connects composite optical fiber, and this method comprises the following steps:

[0056] The first step is to make cable ends respectively for the first cable and the second cable to be connected, and strip off the first central conductor 6 and the second central conductor 7 respectively;

[0057] The second step pulls out the first optical cable 11 from the first central conductor 6 of the first cable, passes the first optical cable 11 through the guide tube 14 and exposes an appropriate length, the guide tube 14 is made of copper material, and There is a disc-shaped protrusion 15 at the middle part. The outer diameter of the guide tube 14 is loosely fitted with the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com