Insulation fin construction of brushless DC motor stator winding

A brushless DC motor and stator winding technology, applied in the shape/style/structure of winding insulation, electrical components, electromechanical devices, etc., can solve the problem of long operation time, no effect, and influence on the inner diameter of the stator core lamination 1, etc. problems, to achieve the effect of saving material costs and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

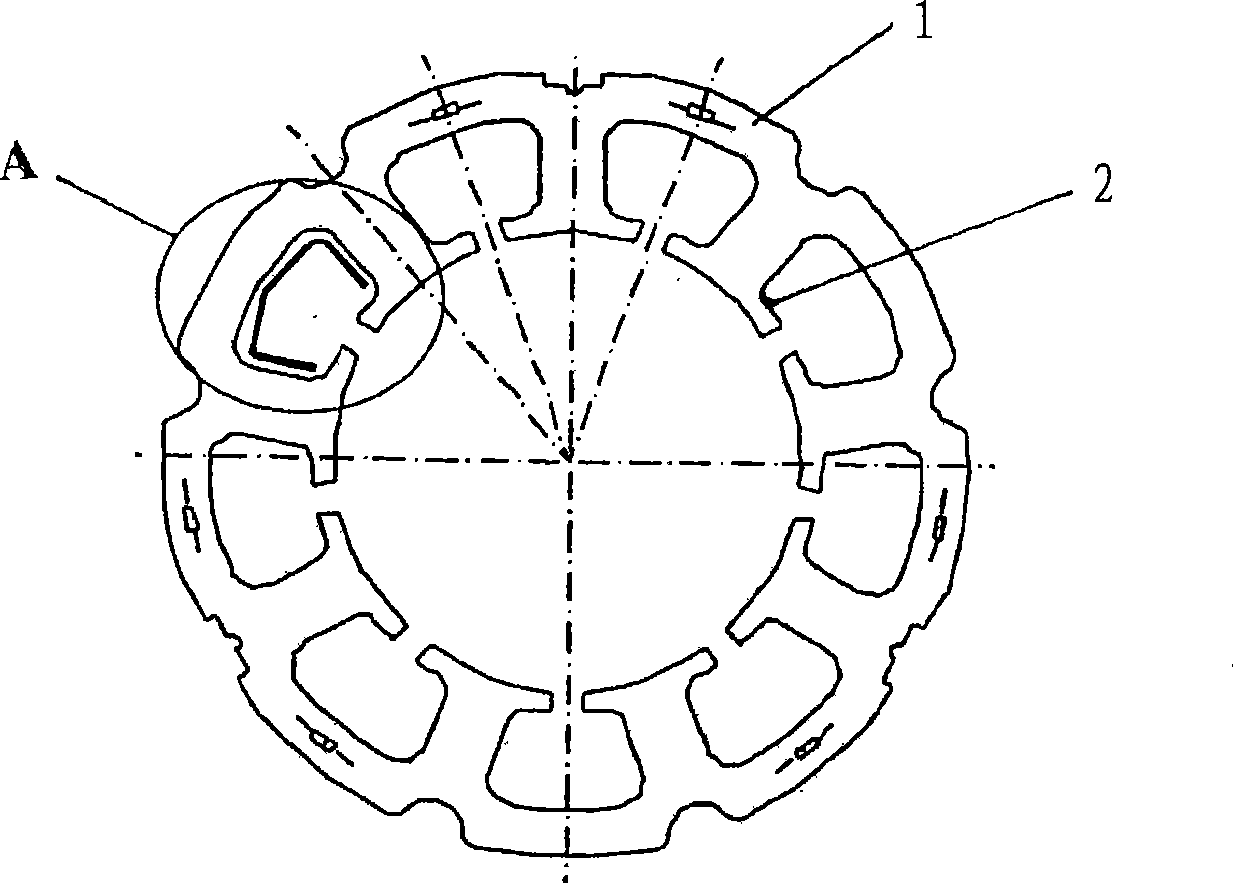

[0026] The insulating sheet structure of the brushless DC motor stator winding of the present invention will be described in detail below with reference to the accompanying drawings and embodiments:

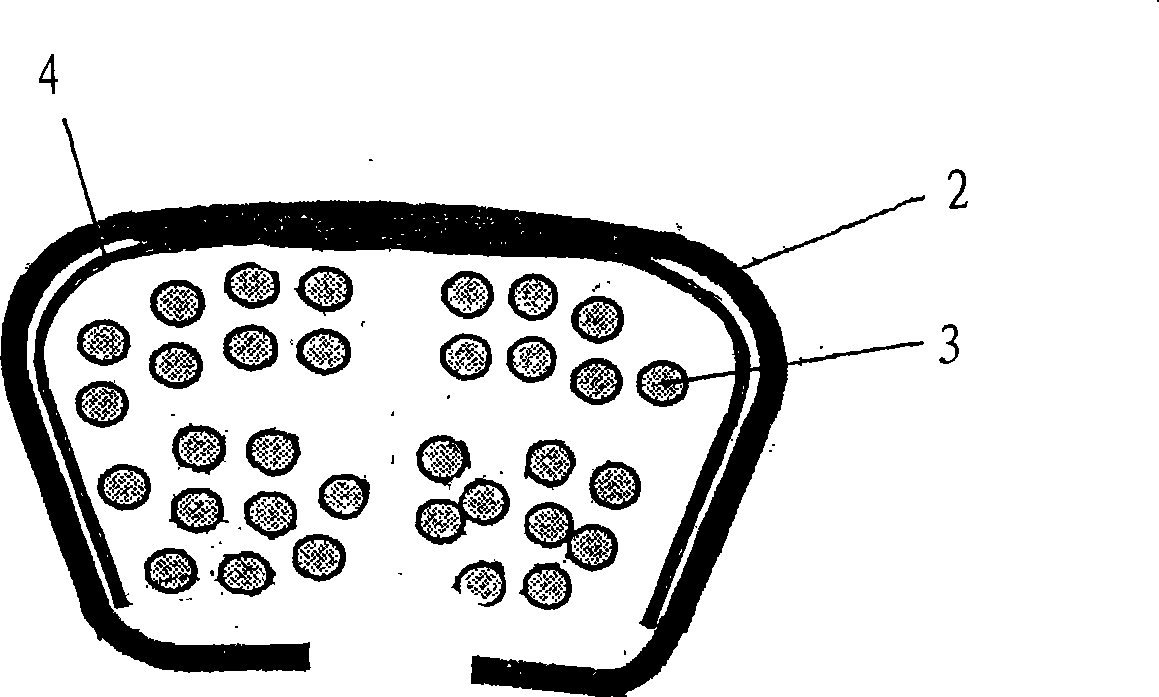

[0027] As shown in FIGS. 4-6 , the stator lamination is composed of a plurality of iron core laminations 1 . Radial wire slots 2 are formed inside the iron core laminations 1 , and coils 3 are wound inside the wire slots 2 . Inside the wire slot 2, with the coil 3 as the center, a plurality of insulating sheets 7 are arranged. The insulating sheets 7 are located between the iron core lamination 1 and the coil 3, and the insulating sheets 7 serve as a link between the coil 3 and the rotor rotating inside the stator. The insulation between them will not cause a short circuit, so that the coil 3 will not be damaged due to the short circuit.

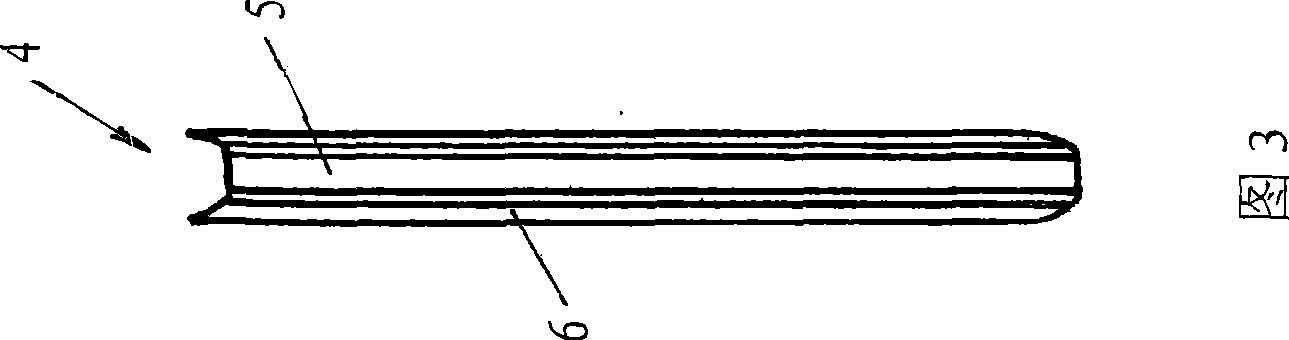

[0028] The insulating sheet 7 is composed of a bottom surface 8 and two side surfaces 9, and the length of the two side surfaces 9 is shorter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com