Coil winding template and ultra-small volume coil forming method

A coil forming and coil technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of dragging deformation, breaking, scratching insulation, and low strength of coil curing and forming, and achieve high-precision forming, The effect of increasing self-strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

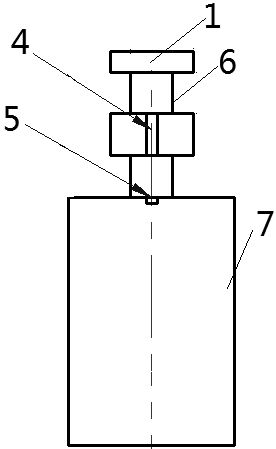

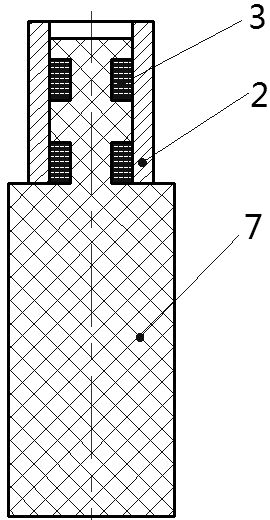

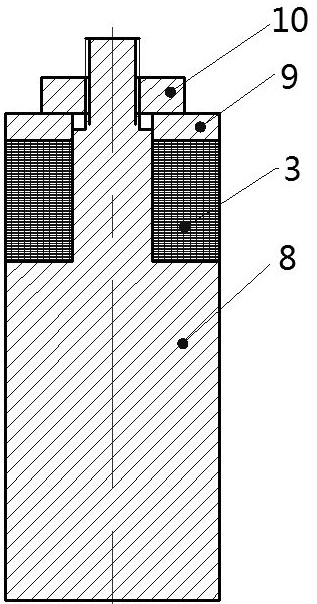

[0035] This embodiment provides a coil winding template, including a coil bobbin 1, a clamping structure 7 and a shaping sleeve 2, the lower part of the coil bobbin 1 is fixed with a clamping structure 7, and the shaping sleeve 2 is set on the coil bobbin 1, the coil bobbin 1 is provided with a coil winding groove 6, and the coil bobbin 1 is made of dissolvable material.

[0036] In the coil winding template provided by the present invention, the coil bobbin 1 is made of dissolvable material, and after the coil bobbin 1 is dissolved in the dissolving solution, it is avoided that the copper wire is broken during the demolding process, the insulating layer is scratched, and the common Clamping deformation, dragging deformation, and the gap between metal parts often jam the winding copper wire, causing the copper wire to be pinched or broken.

Embodiment 2

[0038] On the basis of Embodiment 1, this embodiment provides a coil winding template, wherein there are multiple coil winding slots 6, and multiple coil winding slots 6 are arranged from top to bottom.

[0039] The coil winding template is provided with a plurality of coil winding grooves 6 from top to bottom, and multiple groups of coils 3 can be wound with one copper wire, such as figure 1 , figure 2 As shown, the spacing of the coil winding slots 6 is consistent with the spacing requirements of the two sets of coils 3 used in the voice coil motor. The coil 3 used in the voice coil motor is composed of two sets of hollow copper wire winding coils 3 with an interval of 1 mm, an outer diameter of 2 mm, an inner diameter of 1 mm, and a height of 1 mm. The coil 3 needs to have a certain strength to maintain its own shape.

Embodiment 3

[0041] On the basis of Embodiment 1, this embodiment provides a template for coil winding, the soluble material is polysulfone material, and the shaping sleeve 2 is made of metal.

[0042] The coil frame 1 is made of polysulfone, an organic material, and the coil frame 1 is removed by the organic solvent chloroform to realize high-precision molding of the coil 3 in an ultra-small volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com