Packaging method for integrated optical fiber interferometer module

An optical fiber interferometer and packaging method technology, applied in the field of interferometers, can solve the problems of inapplicability, high price, and complex systems of interferometer systems, achieve good anti-interference and robustness, reduce packaging prices, and expand the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with examples and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

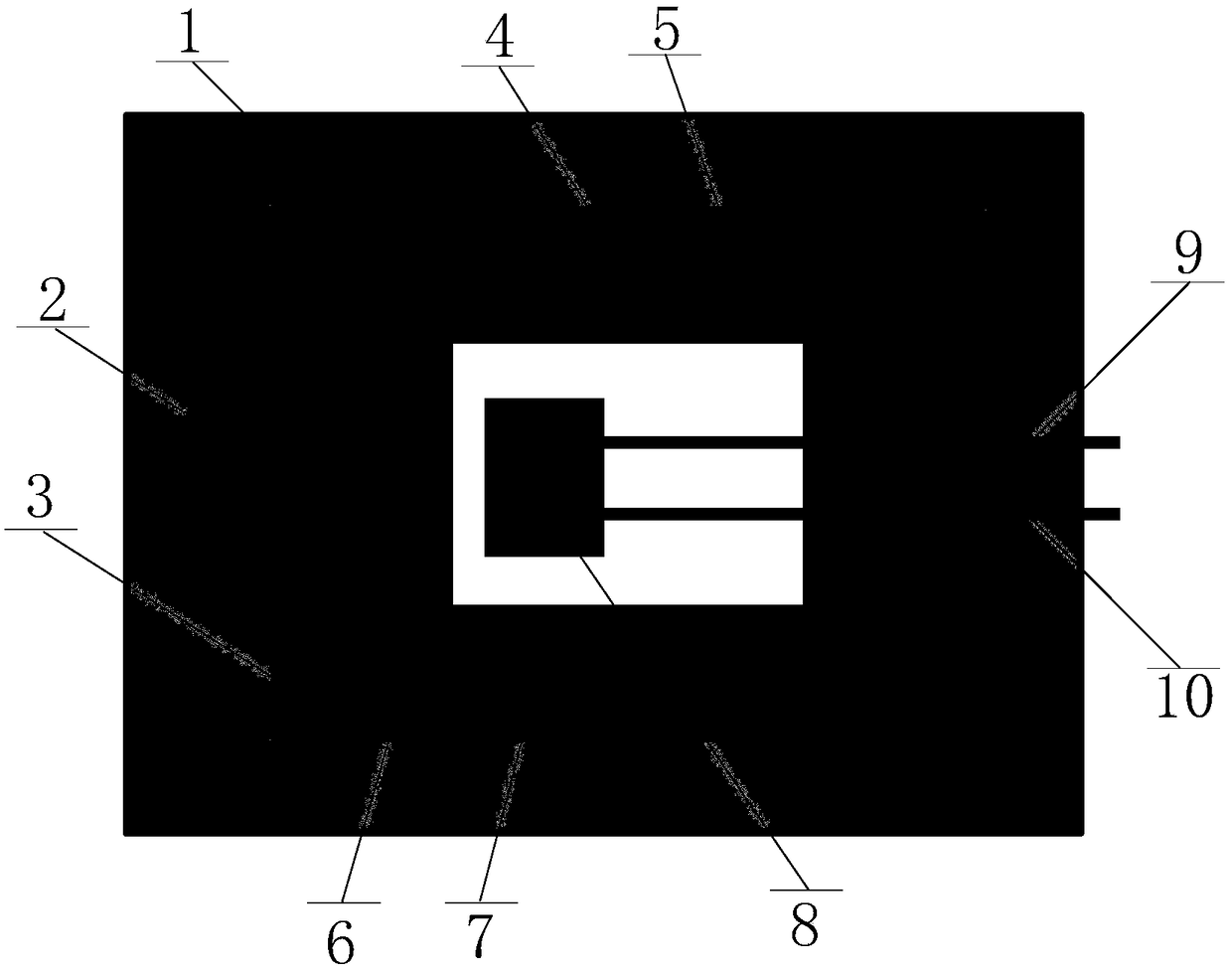

[0020] Plating heat-insulating material on the surface of the first duralumin box 7, carry out the heat-insulating treatment of the first layer; Adopt the spring screw that the integrated optical fiber interferometer module 8 to be packaged is fixed in the duralumin box 7 that the surface is coated with heat-insulating material, to avoid Packaging applies stress to the integrated fiber interferometer module 8; the first duralumin box 7 of the packaged integrated fiber interferometer module 8 is fixed in the second duralumin box 5 with spring screws, and the The box 5 is filled with a grease-like material 6. The grease-like material 6 is a material with a melting point greater than 70°C, a density lower than 1.293g / L, and a low refractive index of 0, which can effectively isolate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com