Improved waveguide and lighting device

A technology for illuminators and light guides, applied in the field of illuminators, can solve problems such as inability to manufacture in size, and achieve the effects of improving transparency and being easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

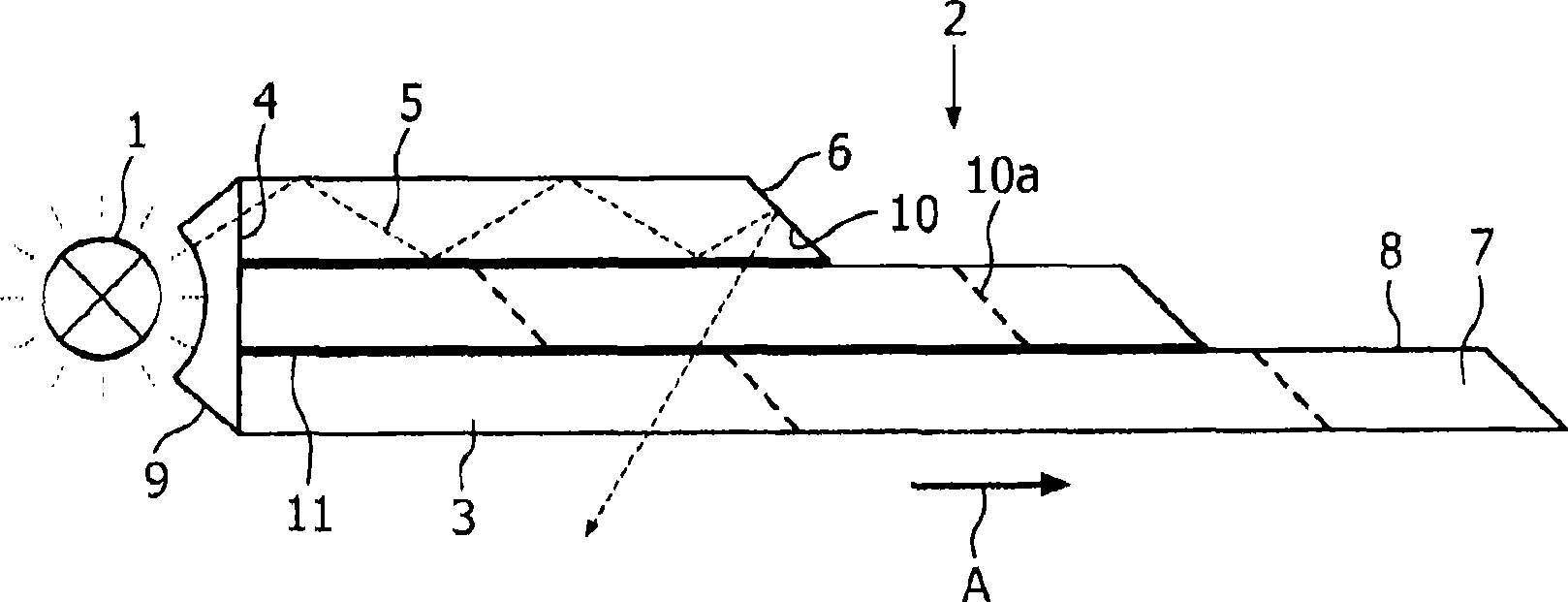

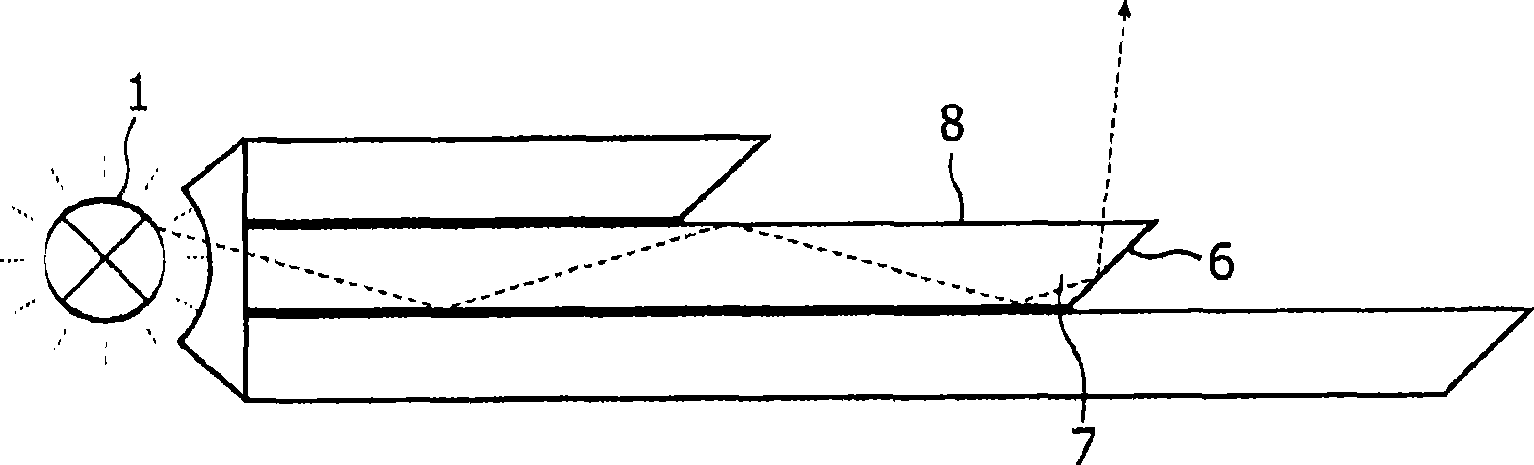

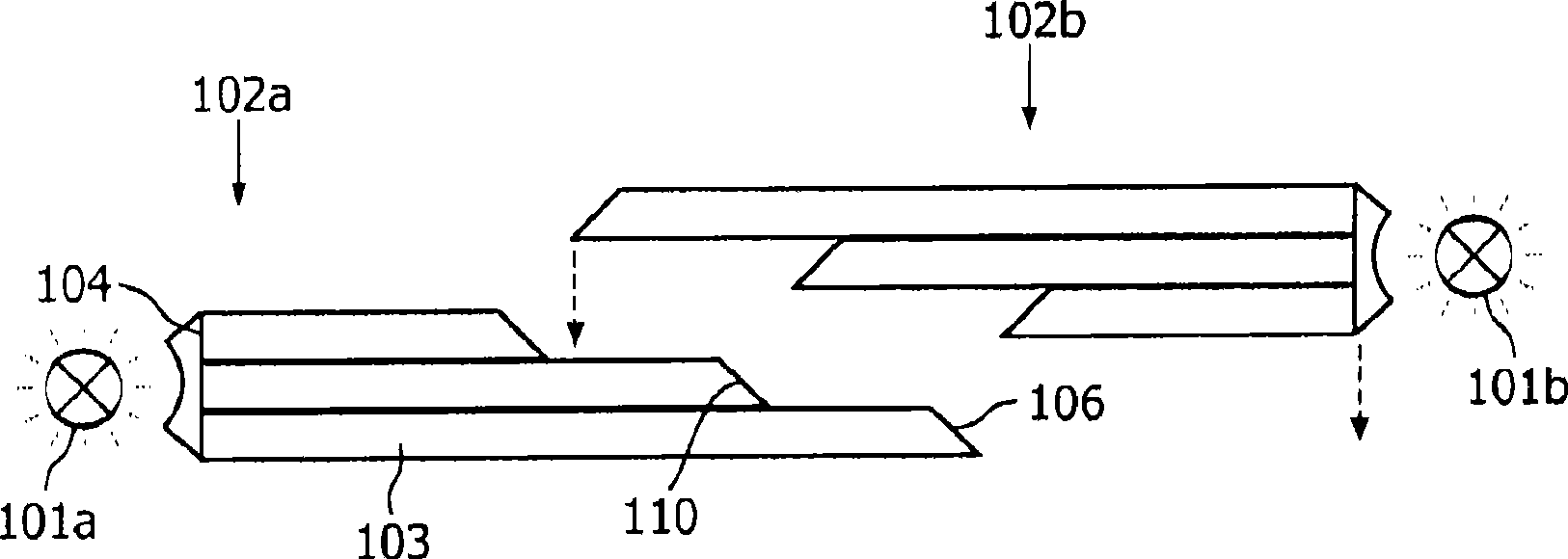

[0034] Figure 1 shows a first embodiment comprising a light source 1 and a stack 2 consisting of flat panel light guides 3 of different sizes. This light source may be an LED, which may be a colored LED, but also a combination RGB-LED, CCFL or other type of suitable light source. Each light guide can be made from a slab made of a single dielectric material or a combination of dielectric materials. Suitable dielectric materials include various transparent materials such as various types of glass, polymethyl methacrylate (PMMA), and the like. The waveguide can also be an air waveguide which is at least partially closed by a waveguide reflector. For reasons of their functionality, waveguides comprising slabs of dielectric material may rely on total internal reflection (TIR), reflectors, or a combination of TIR and reflectors at the edges and / or top and / or bottom surfaces .

[0035] Each light guide has one edge 4 arranged to receive and in-couple light 5 from the light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com