Device for turning pan and automatic/semiautomatic cooking device

A technology for turning pots and power devices, which is applied to cooking utensils, frying pans, household utensils, etc. It can solve the problems of uncontrollable springs, inability to turn over, and fuzzy description of the control process of turning over, so as to improve correctness and accuracy. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

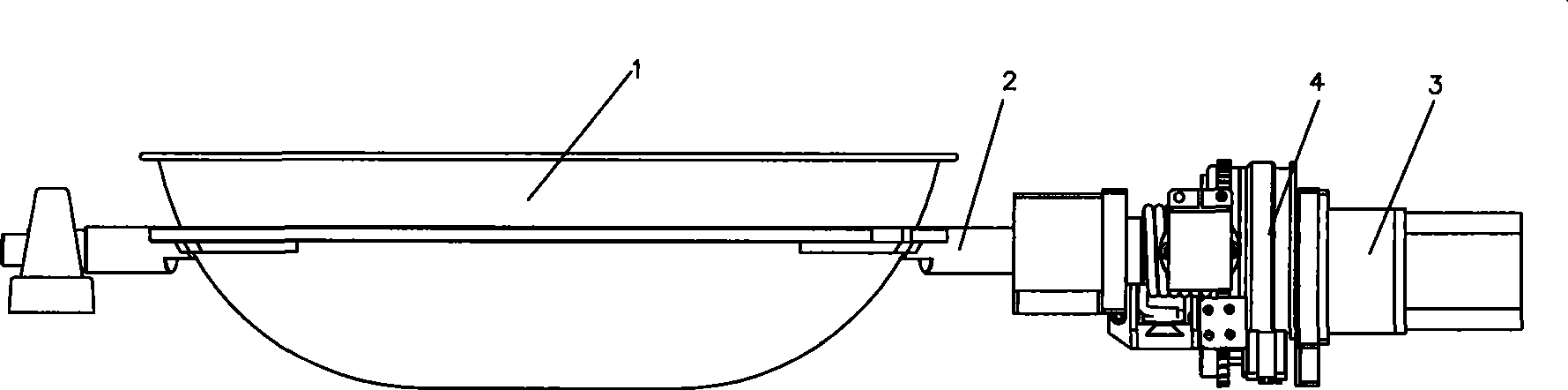

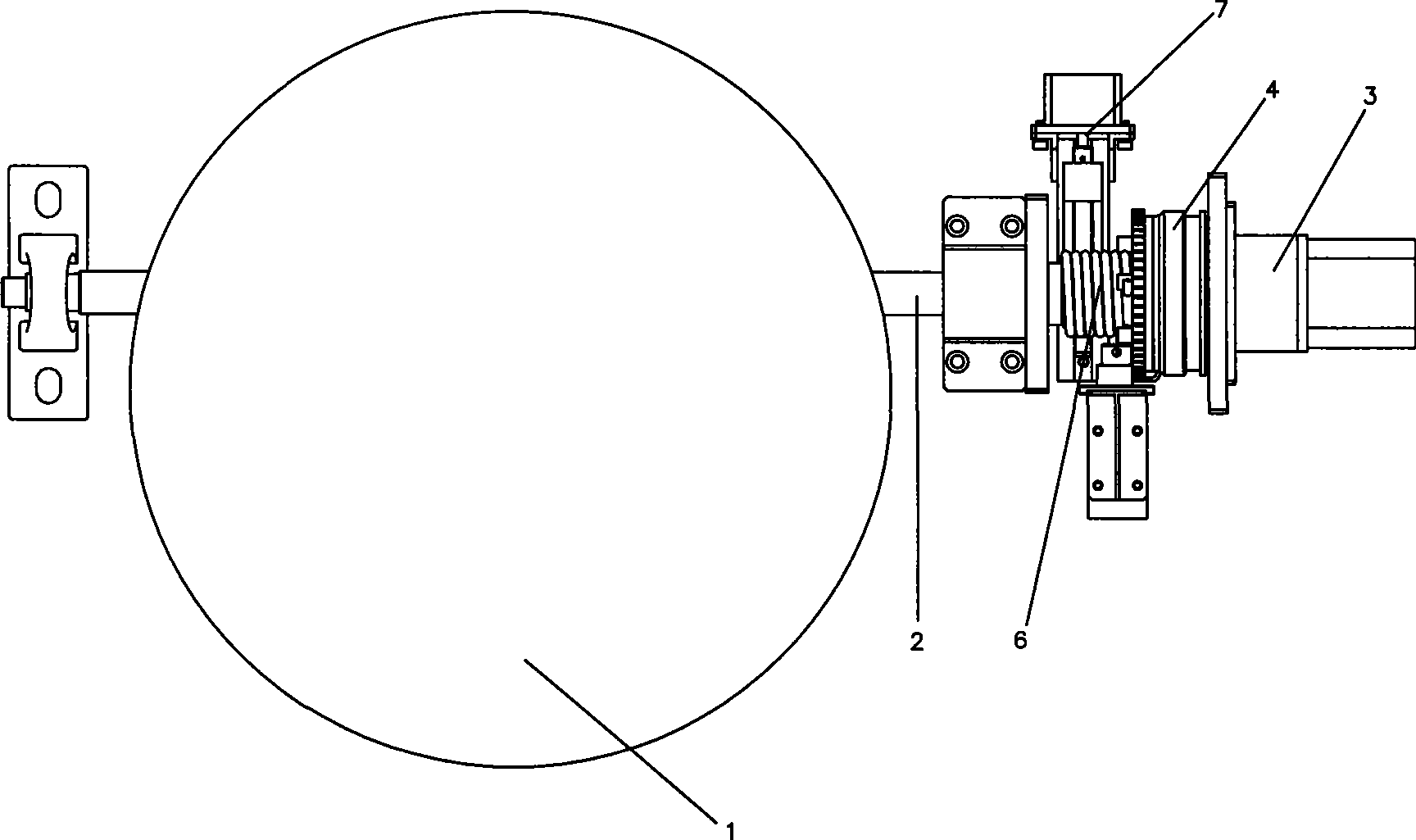

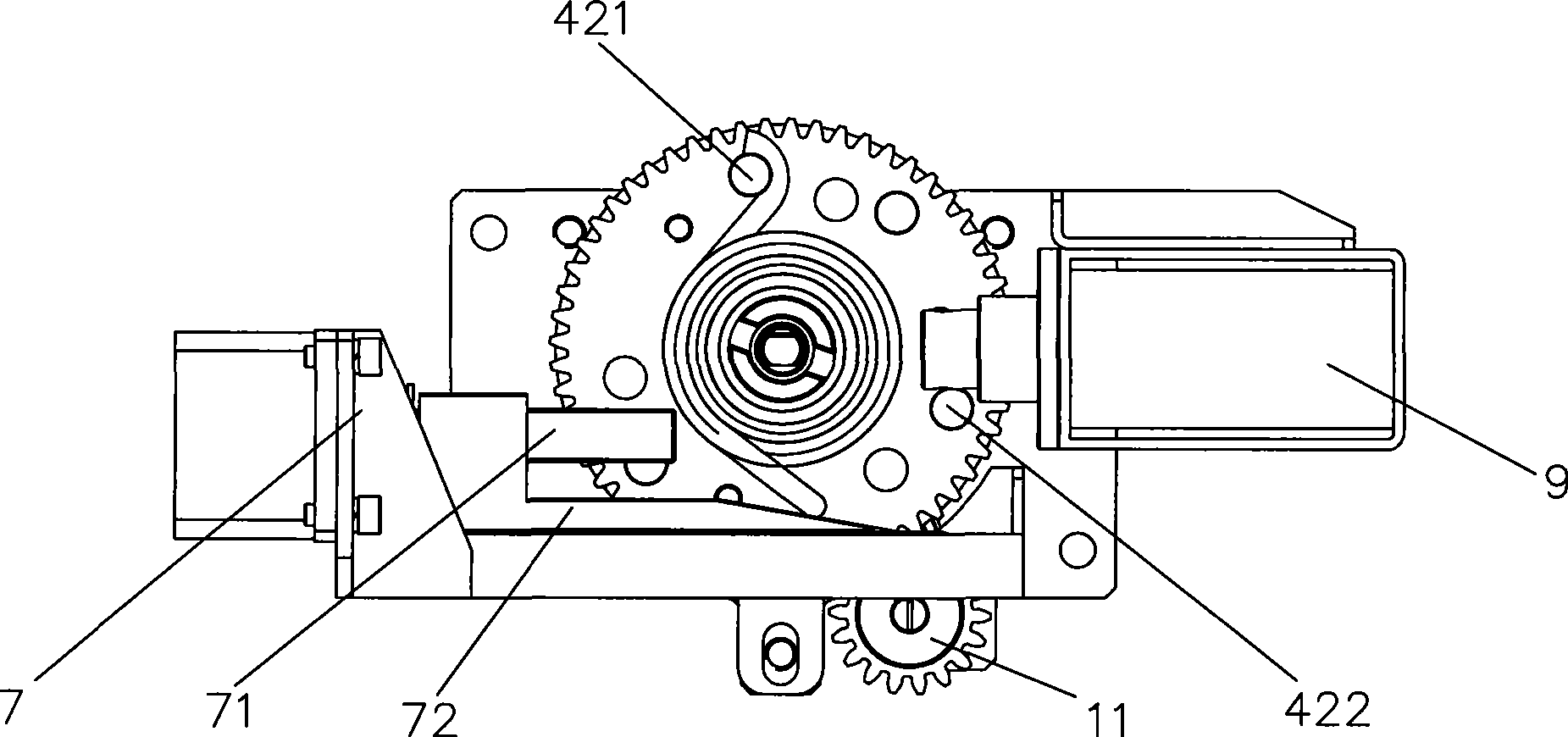

[0047] Figure 1 ~ Figure 4 An embodiment of the pot turning device of the present invention is disclosed. The pot turning device in this embodiment includes a pot body 1, a pot body rotating shaft 2, a motor 3, an electromagnetic clutch 4 and a torsion spring 5, wherein the electromagnetic clutch 4 includes a driving disc 41 and a driven disc 42, and the driven disc 42 is set There are torsion spring driving pin 421 and positioning pin 422, the rotating shaft of motor 3 is connected with the driving disc 41 of electromagnetic clutch 4, torsion spring 5 is enclosed within on the cylindrical protruding end 423 of driven disc 42, one end of pot body rotating shaft 2 Insert in this cylindrical extension end 423, the other end is affixed on the pot plane of pot body 1, and the rotation axis is on the chord line of the pot plane (that is, the vertical centerline of the rotation axis and the pot plane does not intersect).

[0048] The frame of the pot turning device is also provide...

Embodiment 2

[0052] Figure 5 ~ Figure 10 Another embodiment of the pot turning device of the present invention is disclosed. The transmission device in this embodiment adopts a mechanical clutch 5, including an active part 51, a clutch pin 52, an uncoupling torsion spring 53, a limit torsion spring 54, a limit pin 55, two connecting rods 56 and an uncoupling drive shaft 57, wherein, Unhooking torsion spring 53 can act on connecting rod 56, and connecting rod 56 one end connects clutch pin 52, and the other end connects unhooking drive shaft 57; Position pin 55 is fixed on the uncoupling drive shaft 57, and position-limiting torsion spring 54 is fixed on the frame, and position-limiting pin 55 matches with position-limiting torsion spring.

[0053] When turning over the pot, the torsion spring 5 drives the pot body 1 to rotate clockwise, and the active part 51 of the mechanical clutch 5 is driven due to being engaged with the turning gear 13, and then drives the clutch pin 52, the connect...

Embodiment 3

[0055] Figure 11 ~ Figure 12 Another embodiment of the pot turning device of the present invention is disclosed. The form and mode of operation of this device are similar to Embodiment 1, except that the positioning device of the torsion spring 6 adopts a positioning hook 10 . When the torsion spring 6 is torsionally reset, the positioning hook 10 can catch the positioning pin 422 on the driven plate 42 to limit the torsion spring 6 to the initial position.

[0056] In addition, in this device, the torsion adjustment is directly adjusted by the screw structure 8. The end of the bolt in the screw structure 8 contacts the end of the torsion spring 6, and the torsion spring 6 is controlled by the screw in and out of the screw structure 8. The initial energy applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com