Automatic loading and unloading device for processing inner shape of sheet material

A technology for automatic loading and unloading of materials and plates, applied in the field of mechanical processing, can solve the problems of poor product consistency and low production efficiency, and achieve the effects of high work efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

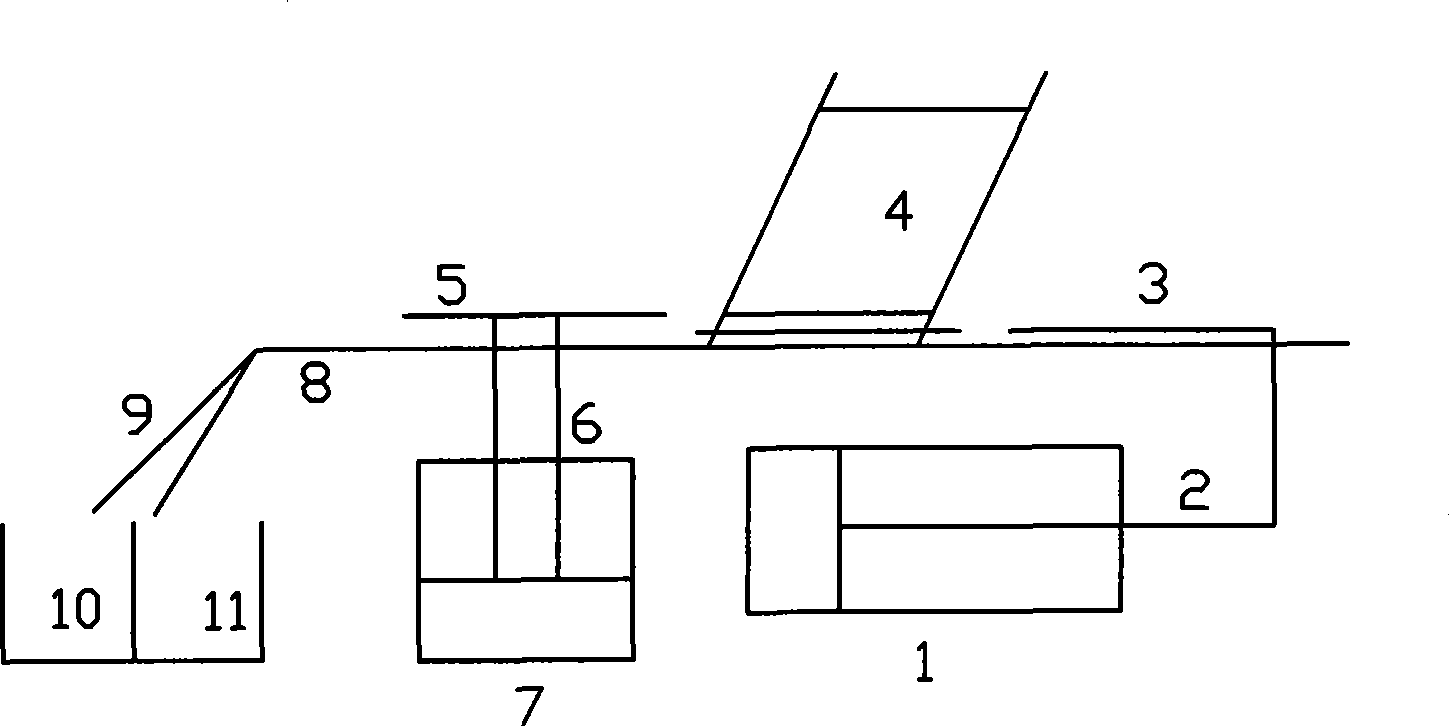

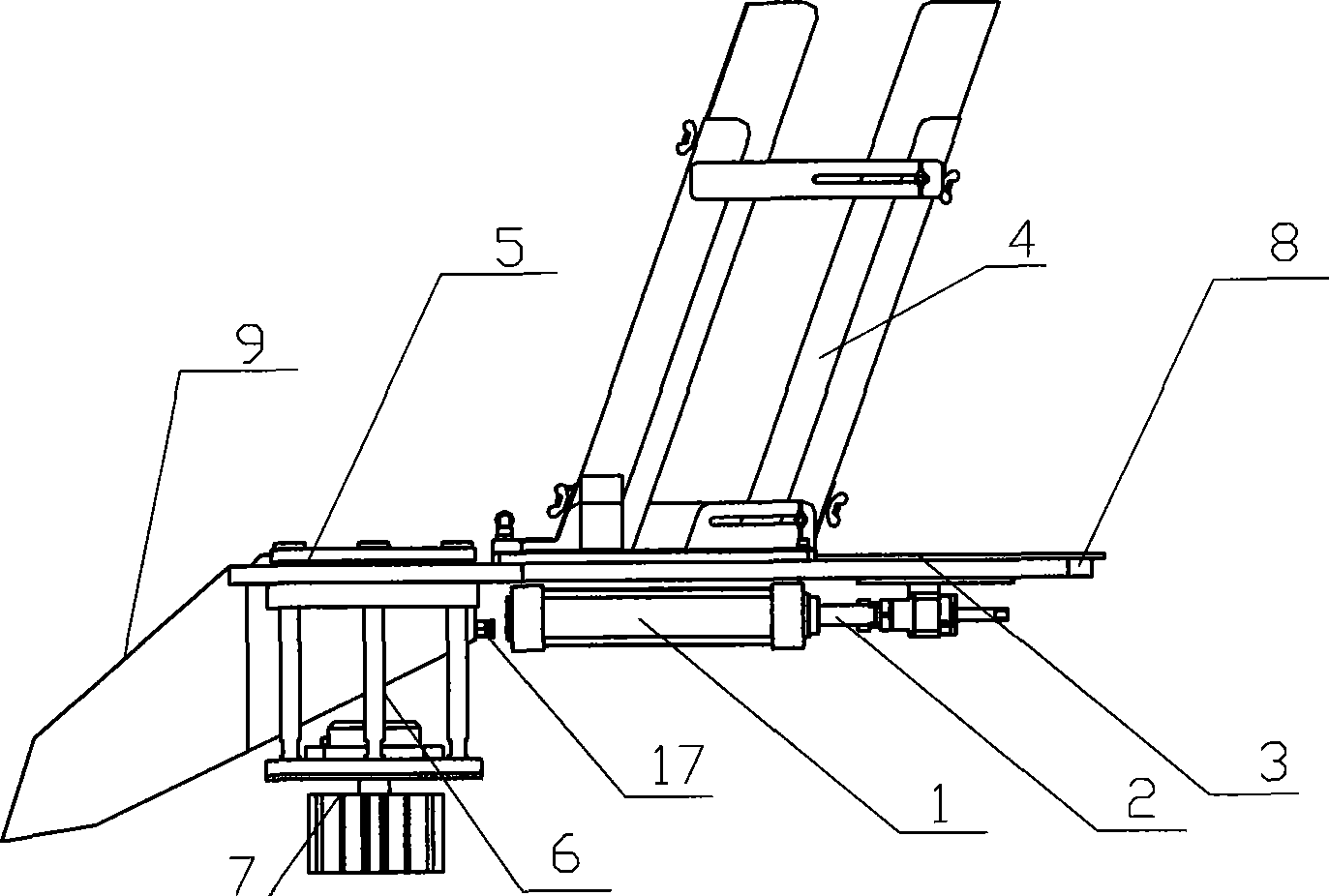

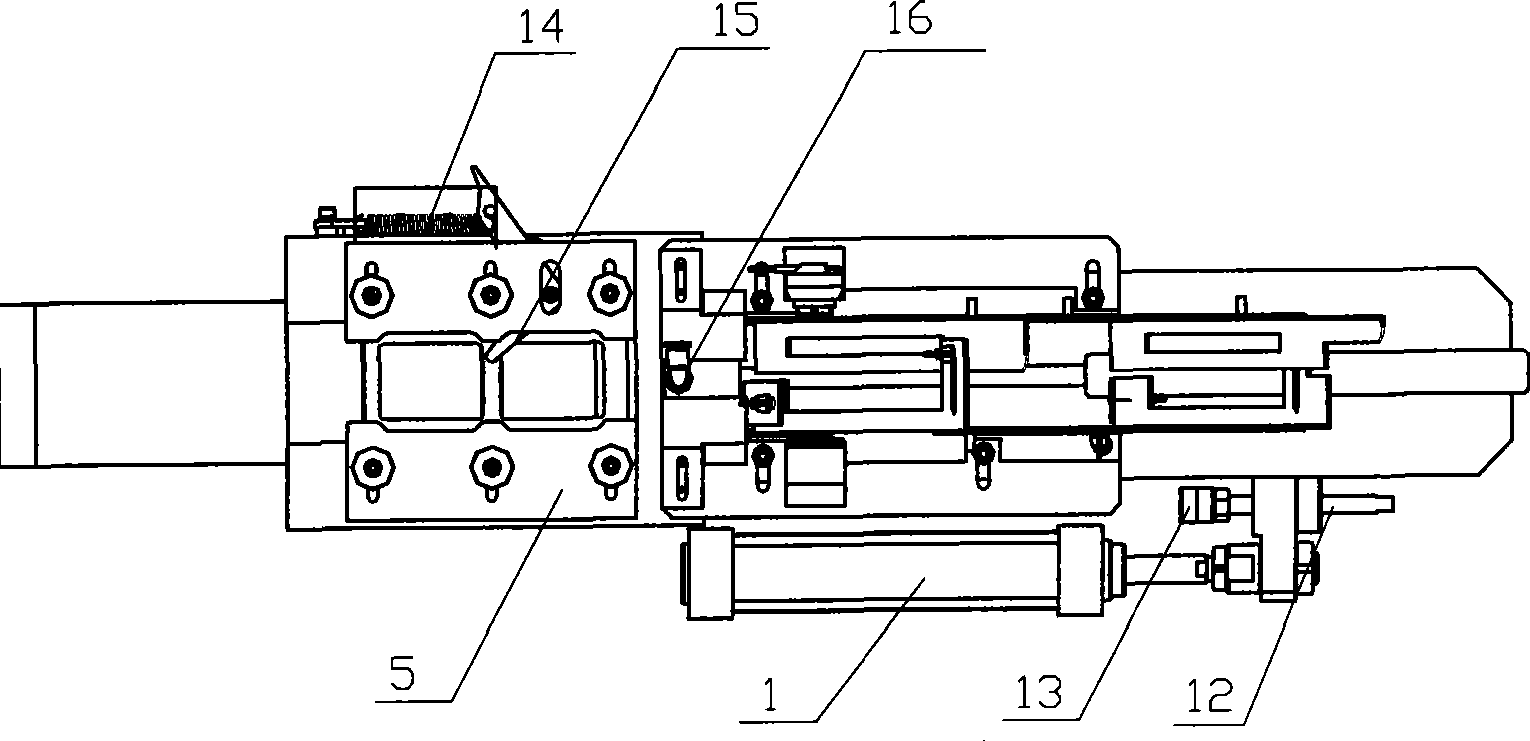

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention consists of a feed cylinder 1, a piston rod 2 of a feed cylinder, a pusher plate 3, a stack 4, a press plate 5, a piston column 6 of a clamping cylinder, a clamping cylinder 7, and a working surface 8 , Double-layer guide groove 9 forms. Among them, the pushing plate 3 is fixedly connected to the piston rod 2 of the feeding cylinder, the stacking stack 4 is installed obliquely on the work surface 8, and the piston column 6 of the workpiece clamping cylinder passes through the work surface 8 and is fixedly connected with the pressure plate 5 The double-layer guide groove 9 for discharging and waste discharge is fixedly connected with the work surface 8 at an angle of 20°~45°, and the feed cylinder 1 and the clamping cylinder 7 are respectively fixed on the work surface 8.

[0017] The stroke adjustment rod 12 is fixed on the piston rod 2 of the feed cylinder. When the feed cylinder 2 pushes the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com