Color printing film imbedding device of in-mold label

A technology of in-mold labeling and color printing film, used in transportation and packaging, object supply, pile separation, etc., can solve the problems of label inclination, inconvenience, and lower efficiency, and reduce defective rate, stable adsorption, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described further by accompanying drawing.

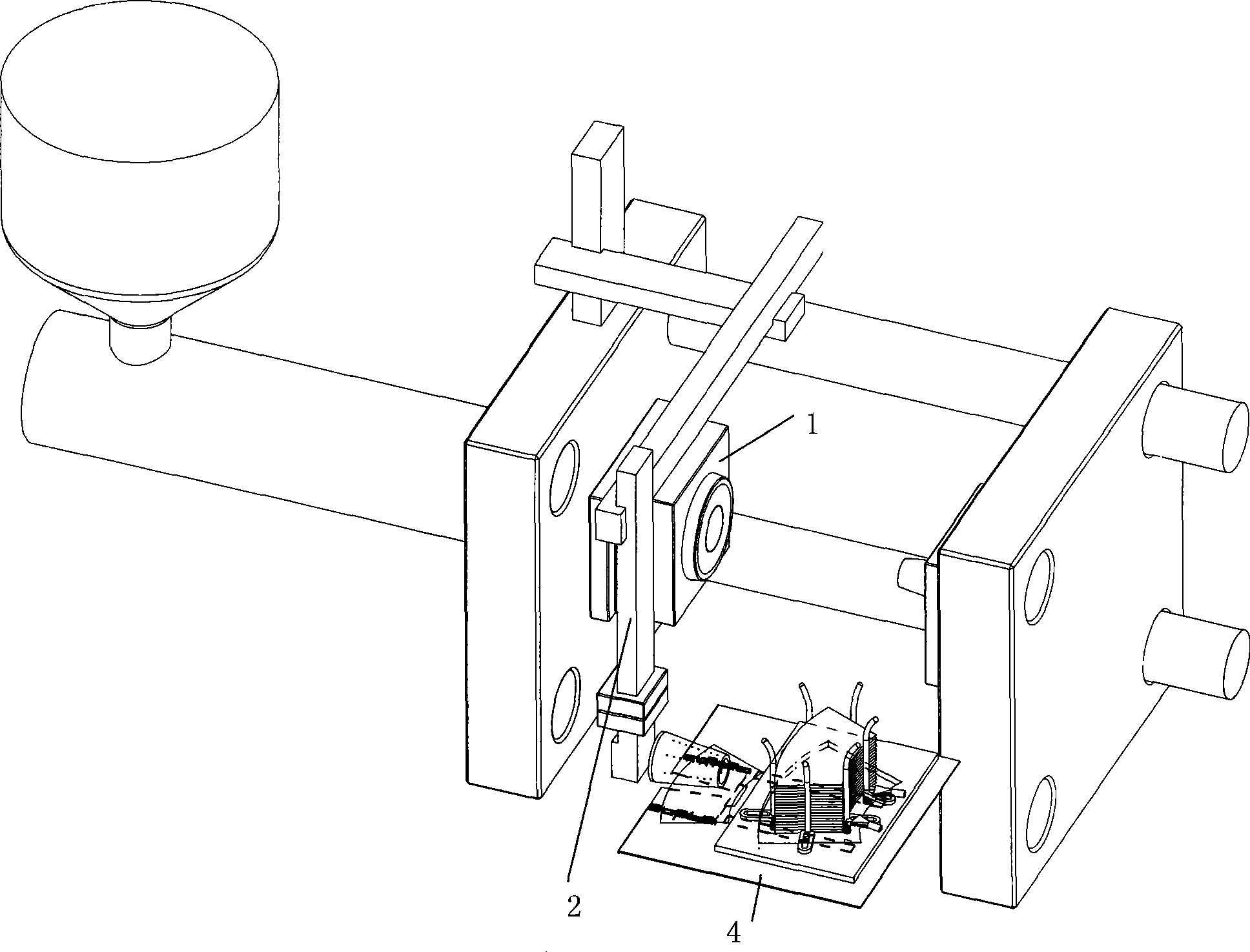

[0018] like figure 1 and Figure 4 As shown, the color printing film insertion device for in-mold labeling includes a molding mold 1 for plastic products and a robotic arm 2 controlled by a computer program. The robotic arm 2 is controlled by a computer and can do up, down, left, right, rotation, and flip and other basic actions, the terminal of the mechanical arm 2 is connected with a die head 21 for absorbing the color printing film 7 , and the die head 21 is connected with an electrostatic generator 3 .

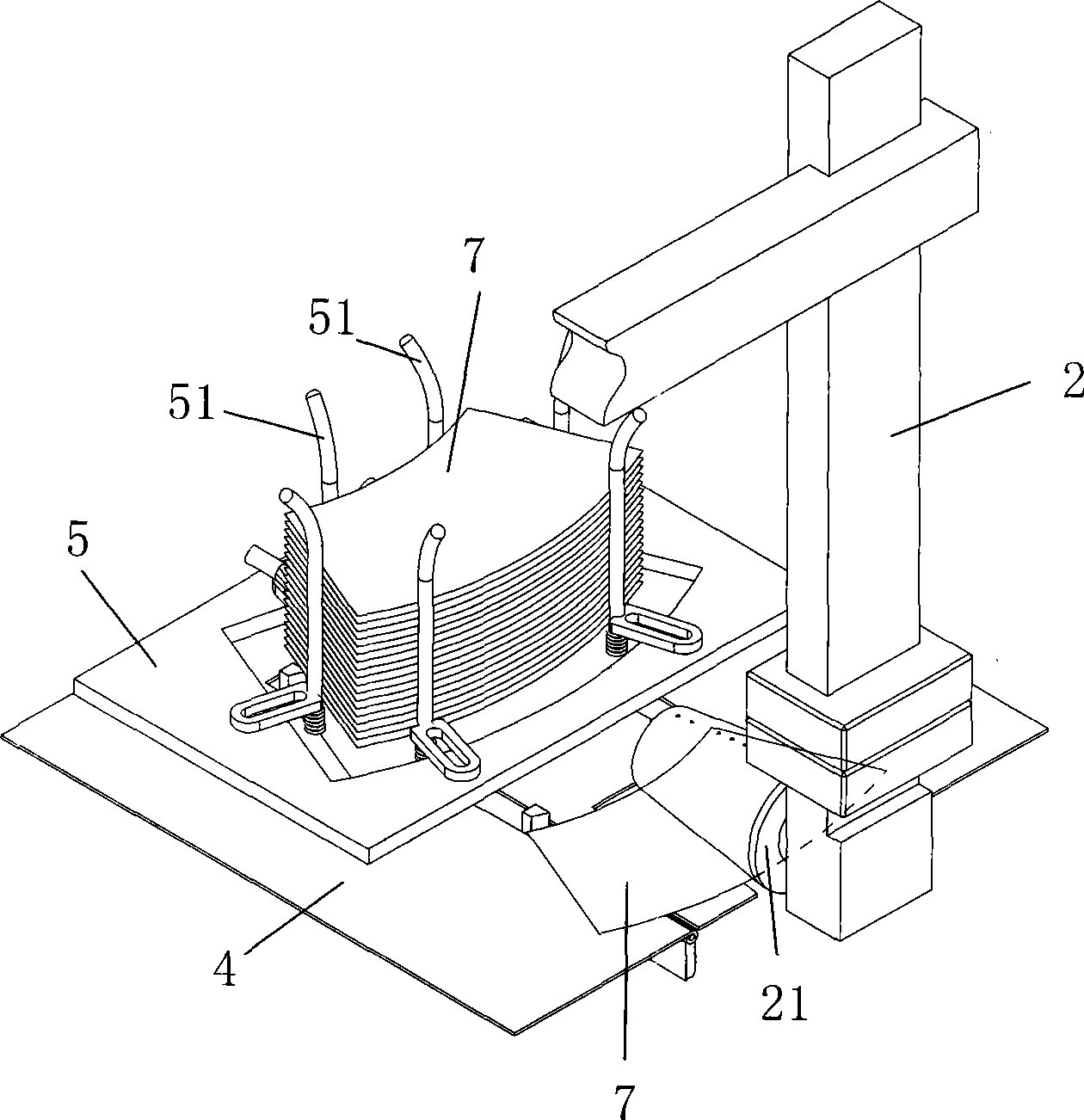

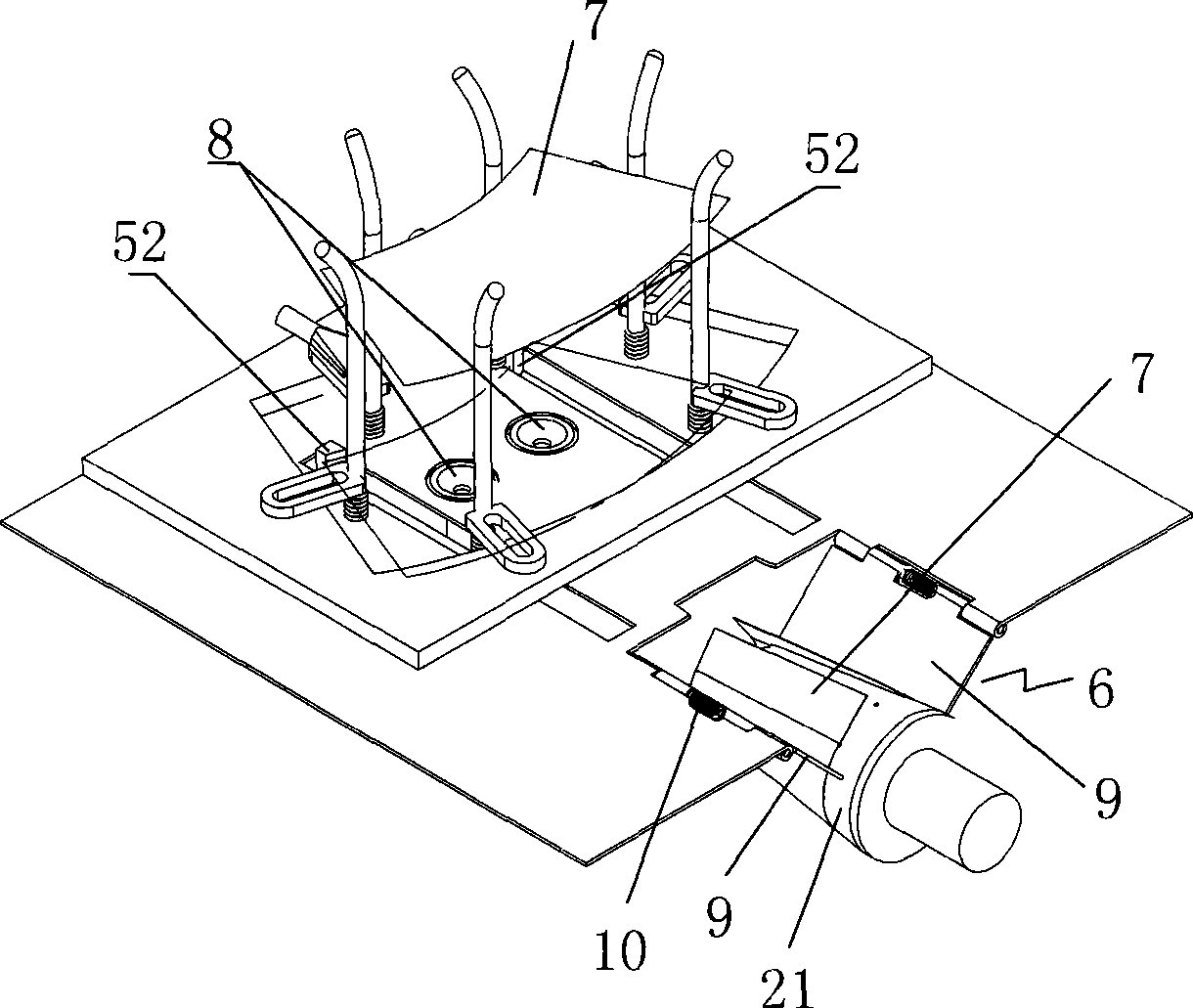

[0019] like figure 2 , 3 , 4, the film rolling machine 4 is provided with a film holder 5 and a film rolling mechanism 6, the film holder 5 includes several positioning rods 51, and the color printing film 7 is placed in the device surrounded by the positioning rods 51, and the positioning The lower end of the rod 51 has a multi-ring tooth structure, so that the color printing film 7 is easil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com