Plastic multi-cavity tube micro-extrusion flow equilibrium detection apparatus

A flow balance and detection device technology, applied in the field of plastic extrusion molding, can solve the problems of wasting manpower and material resources, low design quality and design efficiency, prolonging the mold production cycle, etc., to reduce mold design and manufacturing costs, and reduce trial molds and the number of mold repairs, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

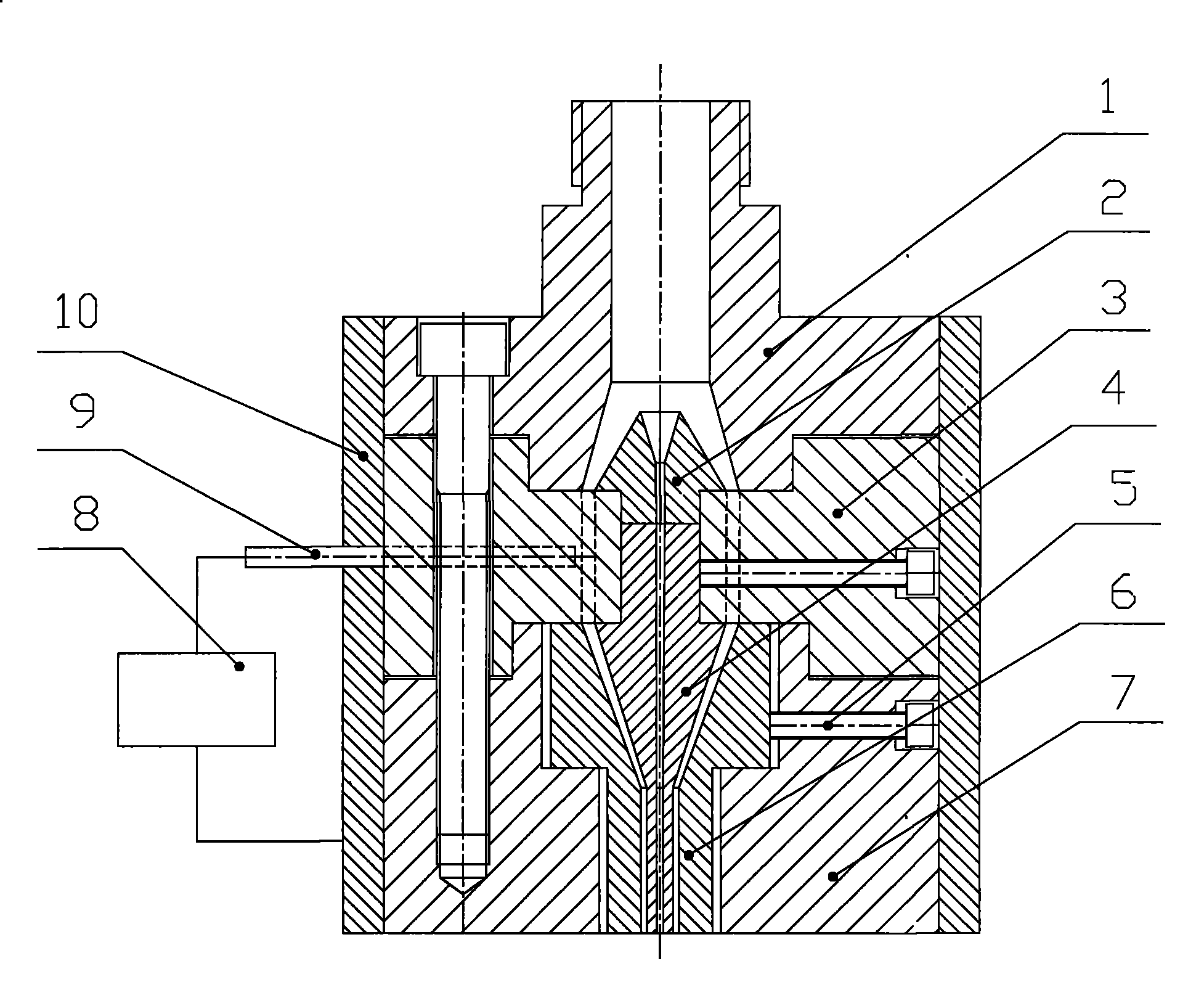

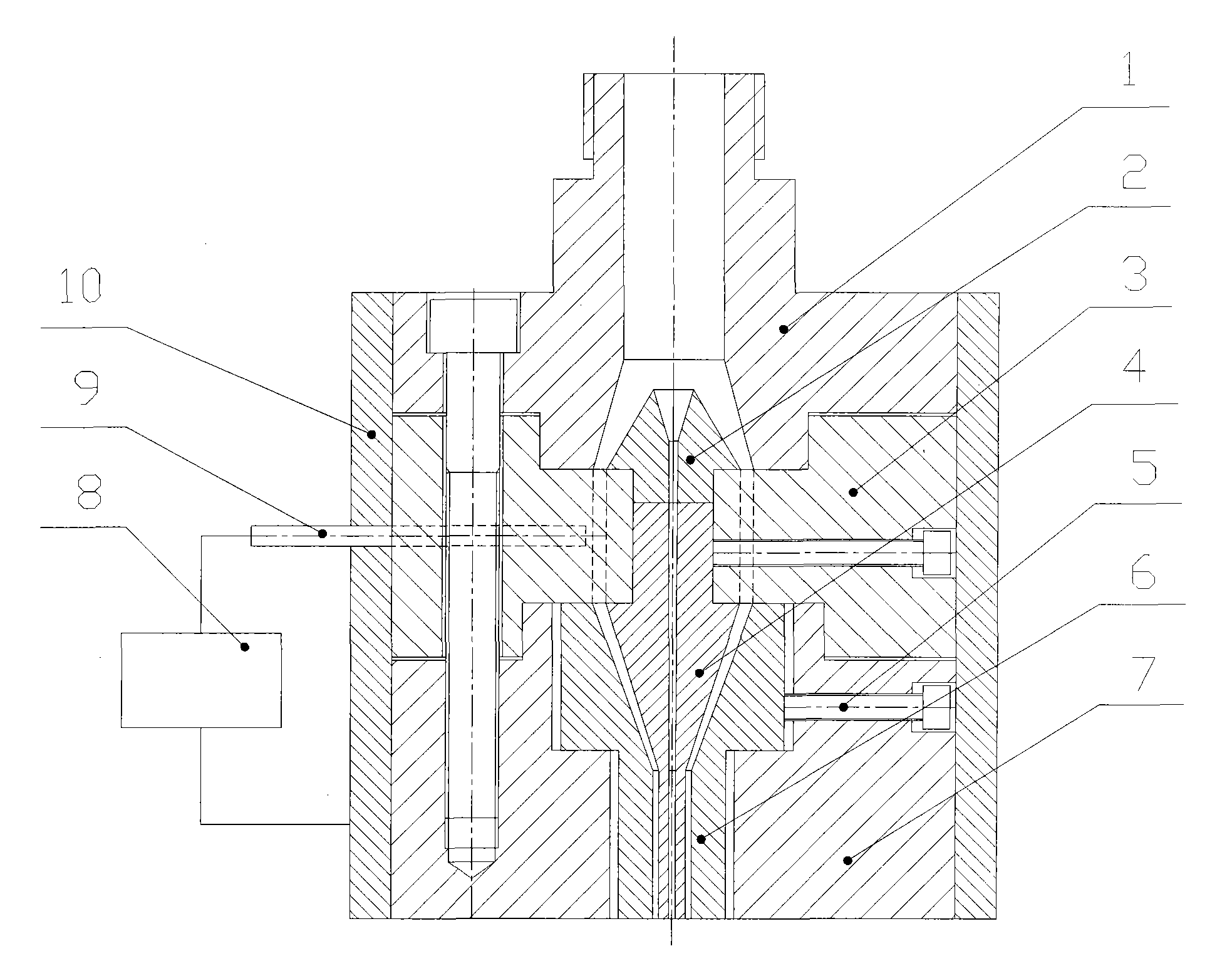

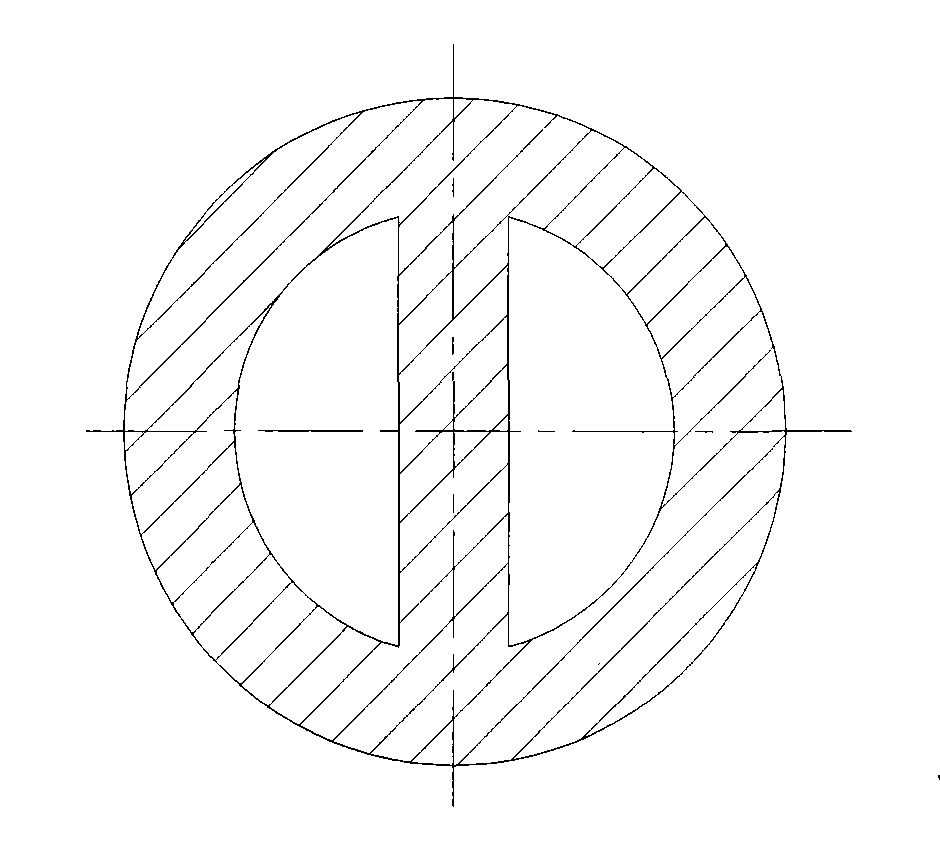

[0012] When the thermoplastic polyurethane elastomer (TPU) is tested at a temperature of 190 ° C, the flow channel structure parameters of the extruded multi-lumen tube flow balance, the cross-section of the multi-lumen tube is shown in Figure 2, and the steps of the embodiment are as follows:

[0013] step 1

[0014] According to the cross-sectional size of the multi-cavity tube, select the splitter cone, core and die insert with certain structural parameters, and assemble them as shown in Figure 1. The splitter cone is installed on the top of the splitter bracket plate; the core is installed under the splitter bracket plate. Fixed by fastening screws; the die insert is mounted on the die backing plate.

[0015] step 2

[0016] Measure the gap between the die insert and the core, and continuously adjust the centering adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com