Preparation technique for purifying graphite by high temperature method

A technology of natural graphite and preparation process, which is applied in the field of preparation process of natural graphite purified by high temperature method, which can solve the problems of large consumption of chlorine gas, poor adaptability of raw ore components, and inconformity with mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

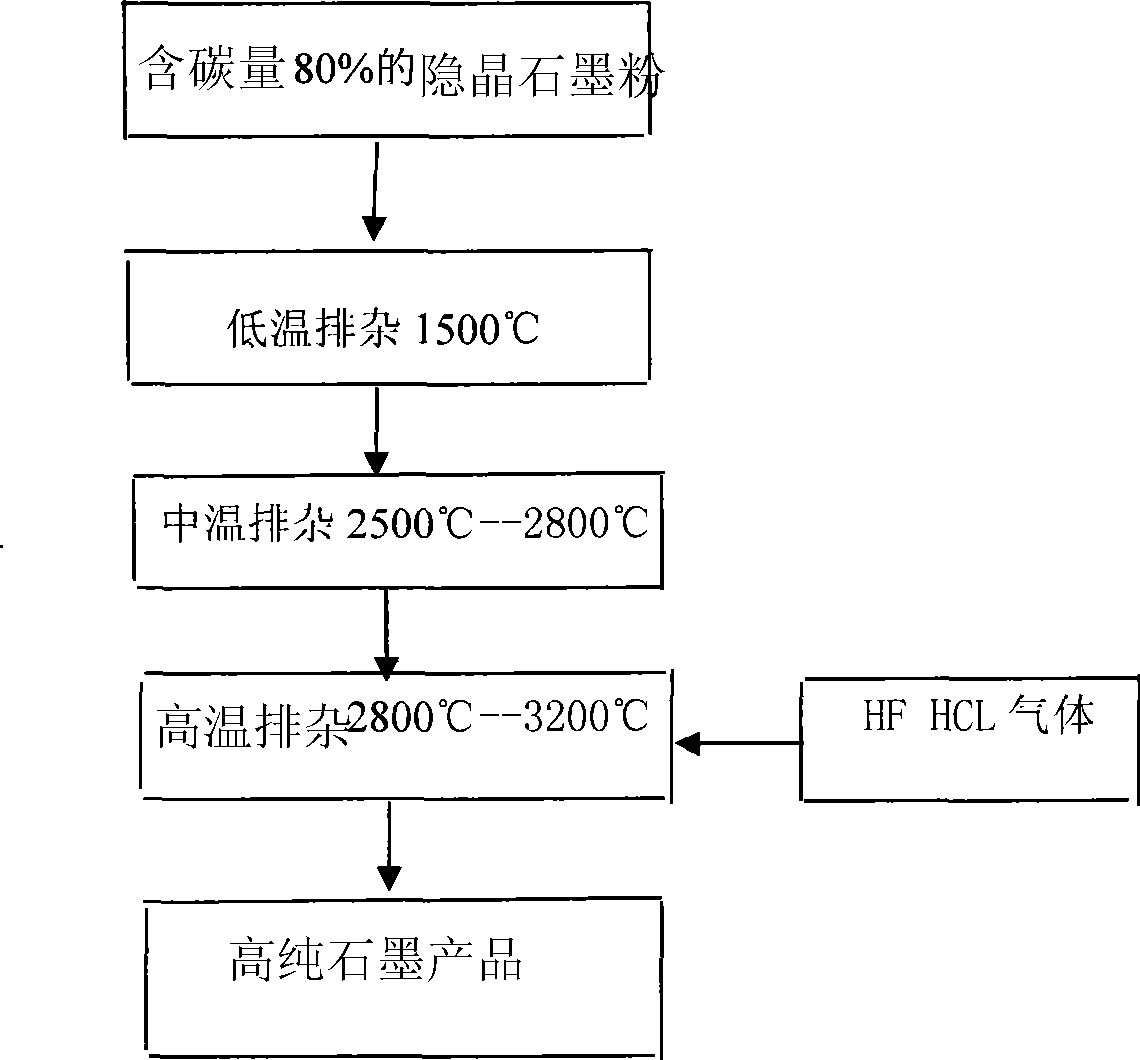

[0006] With reference to the accompanying drawings, this method is implemented with a vertical segmented high-temperature purification furnace. 1000 kg of cryptocrystalline graphite powder with a carbon content of 80% is added to the low-temperature section of the furnace and heated to 1500 ° C for 15 minutes, and part of the low-temperature The impurities at the boiling point are vaporized and discharged; then enter the medium temperature heating zone, the temperature in this zone is 2500°C--2800°C, stay for 25 minutes, and some impurities with corresponding boiling points are gasified and discharged; then enter the high temperature zone, the temperature in this zone 2800°C--3200°C, at the same time add appropriate amount of HF, HCL gas for replacement, the high boiling point metal impurities undergo a replacement reaction to generate low boiling point fluoride and chloride, which are gasified and discharged. At this point, natural graphite will be purified to high-purity grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com