Carbon decreasing synergistic agent for iron ore powder sintering

A technology of synergist and iron ore powder, which is applied in the field of iron ore sintering, can solve the problems of not considering environmental protection, and achieve the effect of good environmental protection effect, obvious use effect and low cost increase

Inactive Publication Date: 2011-01-05

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are many synergist technologies and methods to reduce solid fuel consumption and improve sinter quality, such as the sintering synergist of Langfang Tengda Metallurgical Auxiliary Company, Sihe Chemical Co., Ltd., Henan Tongyu Group Metallurgical Materials Co., Ltd. The common point of this kind of metallurgical additive method is that they all adopt the principle of catalytic combustion, without considering the environmental protection of the materials used, and often use materials with "Cl" sources, such as magnesium chloride (MgCl2), Sodium chloride (NaCl), sodium chlorate (NaClO3), these inorganic substances generate the most harmful gas in the world today - dioxin during the sintering process at a temperature of 300 ° C to 400 ° C. Since 2006, Western industrialized countries have banned the input of "Cl" sources in the production process of sintering and electric furnace steelmaking

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

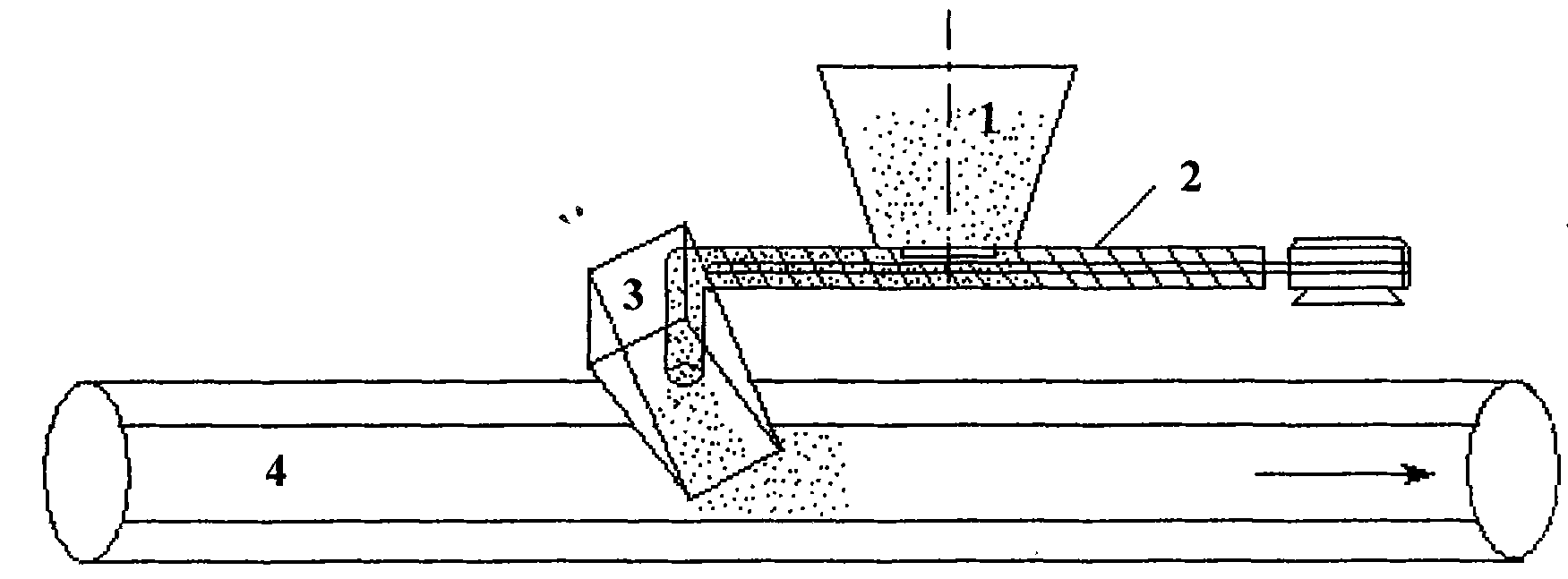

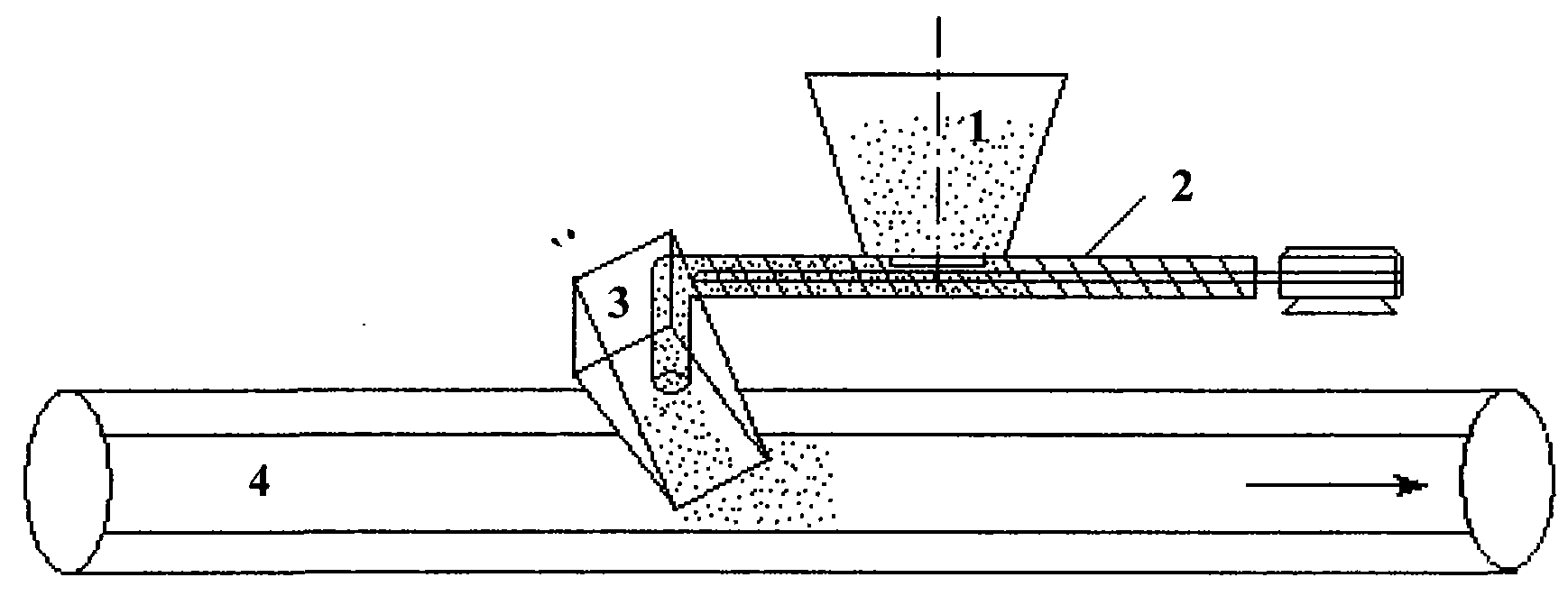

The invention belongs to the iron ore sintering field and relates to an iron ore powder sintering carbon dropping synergist which is applied to the iron ore powder sintering production. The iron ore powder sintering carbon dropping synergist is characterized in that the synergist comprises the components by weight percent of 10-50% of sodium nitrate, 10-50% of boric acid, 5-25% of bentonite, 5-10% of sodium carbonate and 5-10% of fluorite. In the using method, the dried ingredients are finely ground to be 0.052mm, mixed uniformly and sealed into a bag. When in use, the bag is opened and the components are poured into a hopper of the carbon dropping synergist. The adding amount of the synergist is 0.01-0.04% of the dry weight of the mixture. Double-controle of a screw feeder and an electric vibrating feeder is adopted to accurately distribute the mixture on a main belt of the sintering mixture pro rata. The feeders are required to be arranged behind a carbon feeder to ensure that the carbon dropping synergist is uniformly bestrewed on coke powder, coal dust or coke and coal mixed powder. The synergist has the advantages of good environment protection effect, low using amount, less added cost and obvious using effect and can be applied to sintered ores of different types with different alkalinity.

Description

A carbon reduction synergist for iron ore powder sintering technical field The invention belongs to the field of iron ore sintering, and relates to a carbon-reducing synergist for iron ore powder sintering, which is suitable for reducing fuel consumption, improving environmental protection, and increasing output and strength in iron ore powder sintering production. Background technique There are many synergist technologies and methods to reduce solid fuel consumption and improve sinter quality, such as the sintering synergist of Langfang Tengda Metallurgical Auxiliary Company, Sihe Chemical Co., Ltd., Henan Tongyu Group Metallurgical Materials Co., Ltd. The common point of this kind of metallurgical additive method is that they all adopt the principle of catalytic combustion, without considering the environmental protection of the materials used, and often use materials with "Cl" sources, such as magnesium chloride (MgCl2), Sodium chloride (NaCl), sodium chlorate (NaClO3),...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B1/16

Inventor 许满兴许赞文张玉兰

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com