LCD with vertical alignment mode

A liquid crystal display, vertical alignment technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of inability to realize high-channel number drive, inability to realize multi-domain display, static electricity, friction damage, etc., and achieve low cost and high reliability High, short design cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

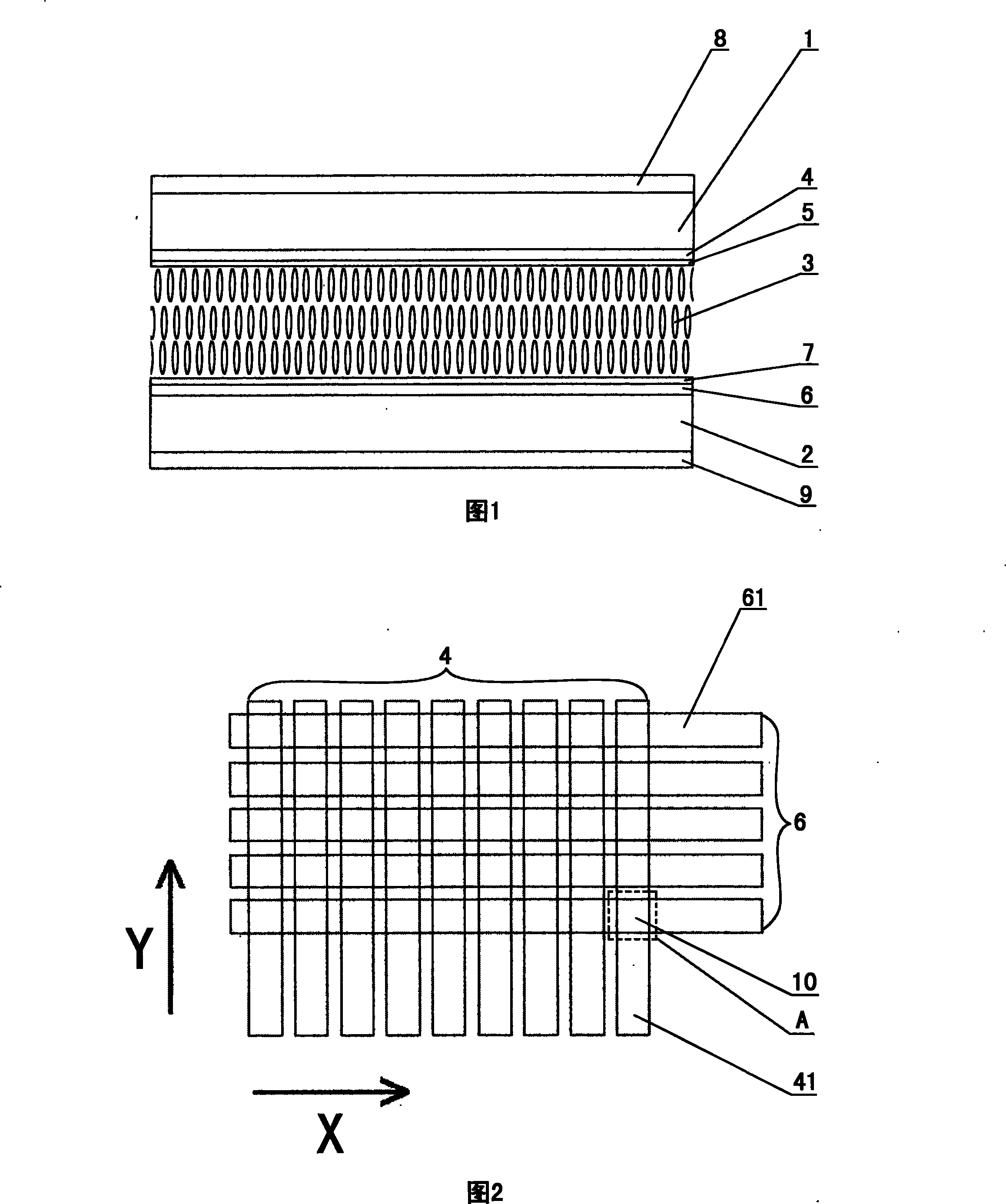

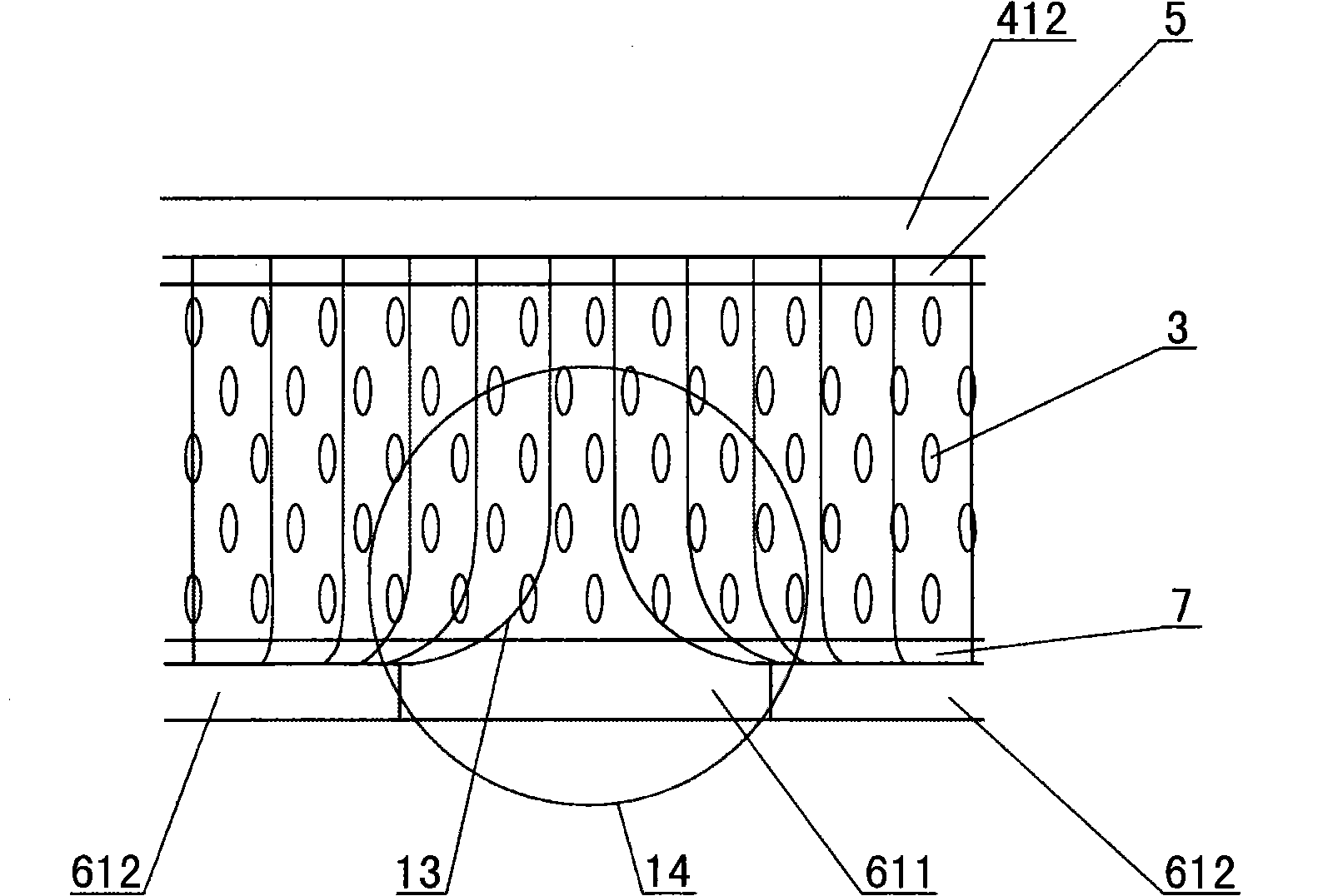

[0027]As shown in Figure 1, this vertical alignment mode liquid crystal display comprises an upper transparent substrate 1, a lower transparent substrate 2 and a negative liquid crystal layer 3; There is an upper vertical alignment layer 5; the inner surface of the lower transparent substrate 2 is provided with a lower electrode 6, and the inner surface of the lower electrode 6 is provided with a lower vertical alignment layer 7; the negative liquid crystal layer 3 is arranged on the upper vertical alignment layer 5 and the lower vertical alignment layer. Between the layers 7; the outer surface of the upper transparent substrate 1 is provided with an upper polarizer 8, and the outer surface of the lower transparent substrate 2 is provided with a lower polarizer 9. The aforementioned inner side refers to the side facing the negative liquid crystal layer 3 , and the outer side refers to the side away from the negative liquid crystal layer 3 .

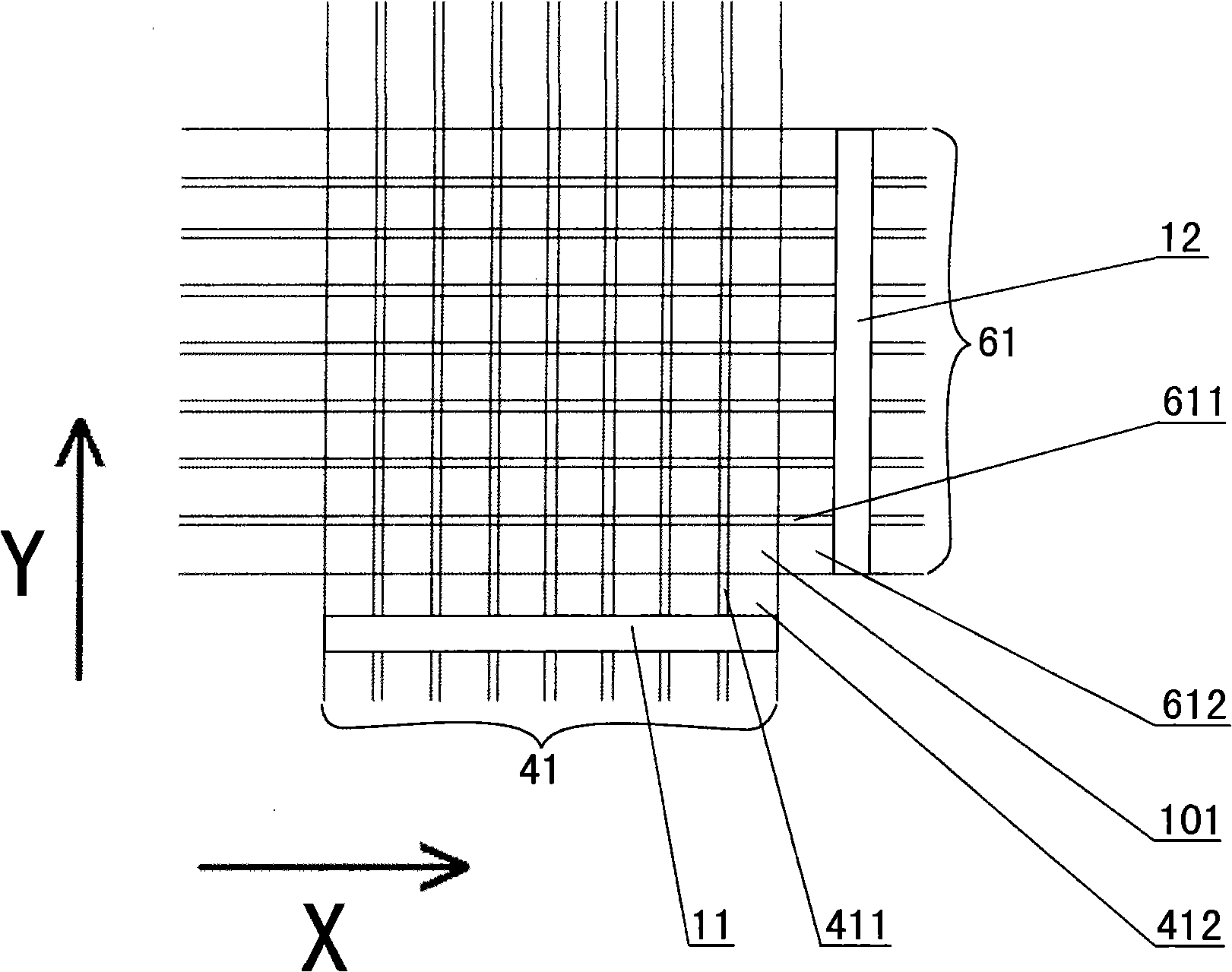

[0028] As shown in Figure 2, the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com