Tooth for dental arch model and manufacturing method thereof

A model and dental arch technology, applied in the field of manufacturing, can solve problems such as difficult to cut caries, and achieve the effects of reducing dust inhalation, reducing dust scattering, and suppressing stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

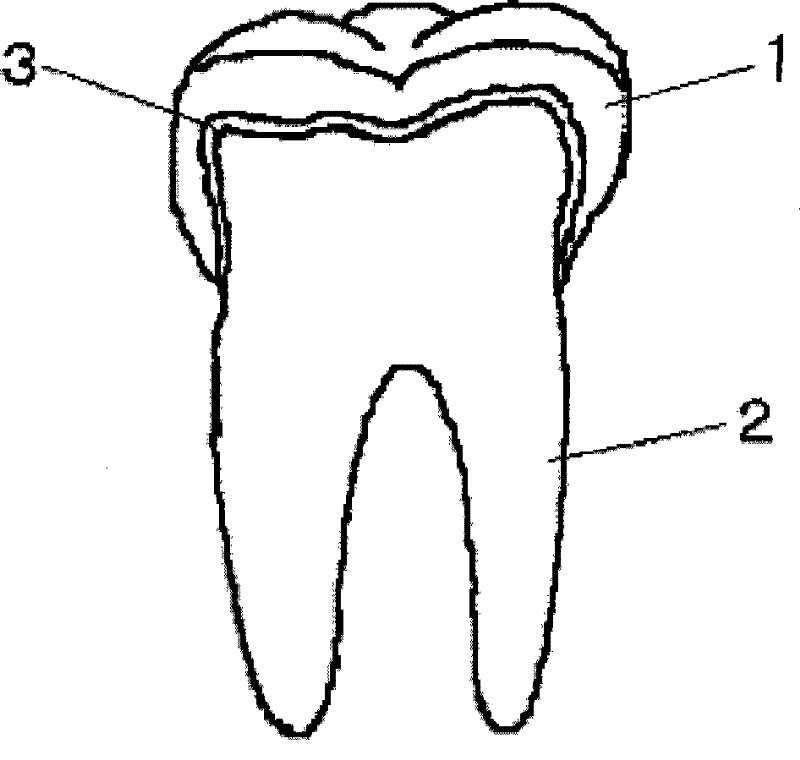

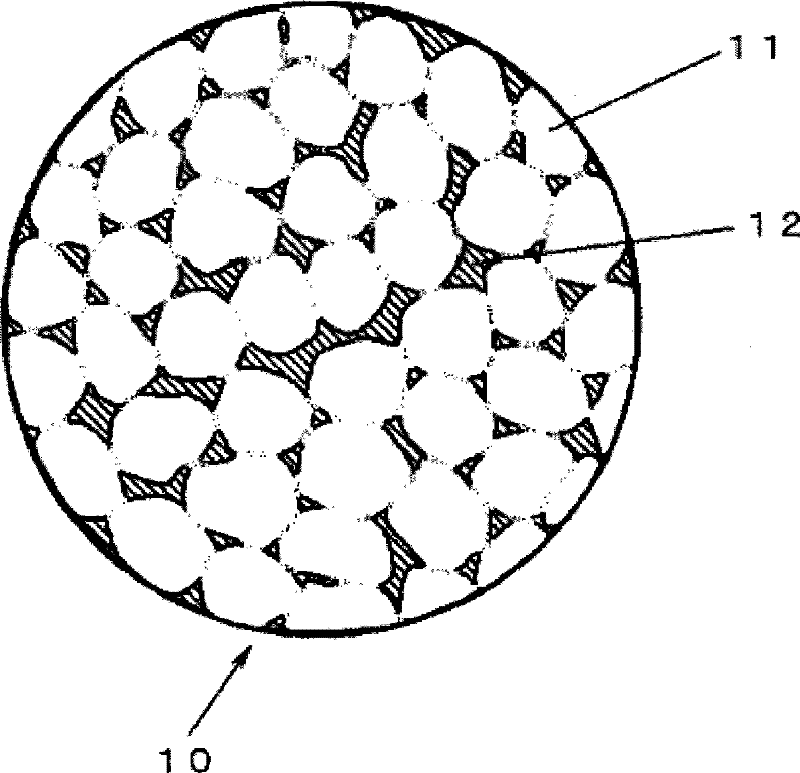

[0225] Use 1 kg of alumina pellets (Al 2 o 3 : 26%, SiO 2 : 44%, average particle size: 0.25 μm, stearic acid: 30%) were injection molded in a tooth-shaped mold to obtain an injection molded body.

[0226] The resulting injection molded body having the shape of the enamel portion was degreased, and then sintered (1,300° C., residence time: 10 minutes) to obtain a sintered body 1-1.

[0227] 1 kg of alumina pellets for CIM (Al 2 o 3 : 26%, SiO 2 : 44%, average particle size: 3.0 μm, stearic acid: 30%) were injection molded in a tooth-shaped mold to obtain an injection molded body.

[0228] The resulting injection molded body having the shape of the dentin portion was degreased and sintered (1,000° C., residence time: 10 minutes) to obtain a sintered body 1-2.

[0229] 1kg of CIM was made of alumina pellets (Al 2 o 3 : 68%, SiO 2 : 2%, average particle size: 0.3 μm, stearic acid: 30%) were injection molded in a tooth-shaped mold to obtain an injection molded body.

[0...

Embodiment 2

[0260] In order to examine the effect of the amount of binder on the shrinkage of the sintered body during pellet making, sintered bodies 5 and 6 were made in the same manner as in Comparative Example 1 except that the amount of stearic acid was changed to 18%.

[0261] In the sintered bodies 5 and 6, the enamel portion and the dentin portion were sufficiently bonded, and the cutting feeling of both the enamel portion and the dentin portion was similar to a natural tooth.

[0262] It has been found that cracking or chipping during cutting caused by differences in thermal expansion and contraction upon firing between dentin and enamel can be prevented by controlling the amount of binder during pelleting.

Embodiment 3

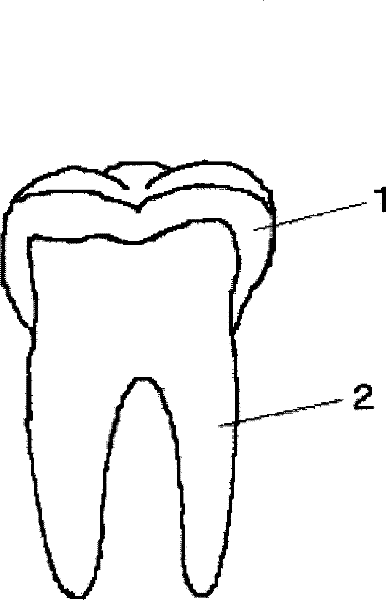

[0264] The enamel and dentin portions of the sintered bodies 1-1, 1-2, 2-1, and 2-2 produced in the same manner as in Example 1 were bonded using low-melting glass powder, and then the cutting feeling was checked.

[0265] IP9021 (low melting point glass, sintered at 575° C.) manufactured by Heraeus K.K. was used as the glass powder to obtain sintered body 7 , and IP9049 (low melting point glass, sintered at 610° C.) was used to obtain sintered body 8 .

[0266] table 3

[0267] Adhesiveness Cutting feeling debris Sintered body 7 C B C Sintered body 8 C B C

[0268] A: Good results similar to natural teeth were obtained.

[0269] B: Although sufficient adhesion can be confirmed, chipping partially occurs.

[0270] C: Excellent when compared with conventional teeth.

[0271] Regarding adhesiveness, dentin and enamel are bonded to form an integral material. Although a cutting feel similar to that of natural teeth was obtained, cracks occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com