Malodorous gas processing system for sanitary landfill yard

A malodorous gas and treatment system technology, applied in deodorization, waste disinfection or sterilization methods, smoke removal, etc., can solve problems such as reducing leachate production, reduce leachate production, and improve the overall impression , improve the effect of visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

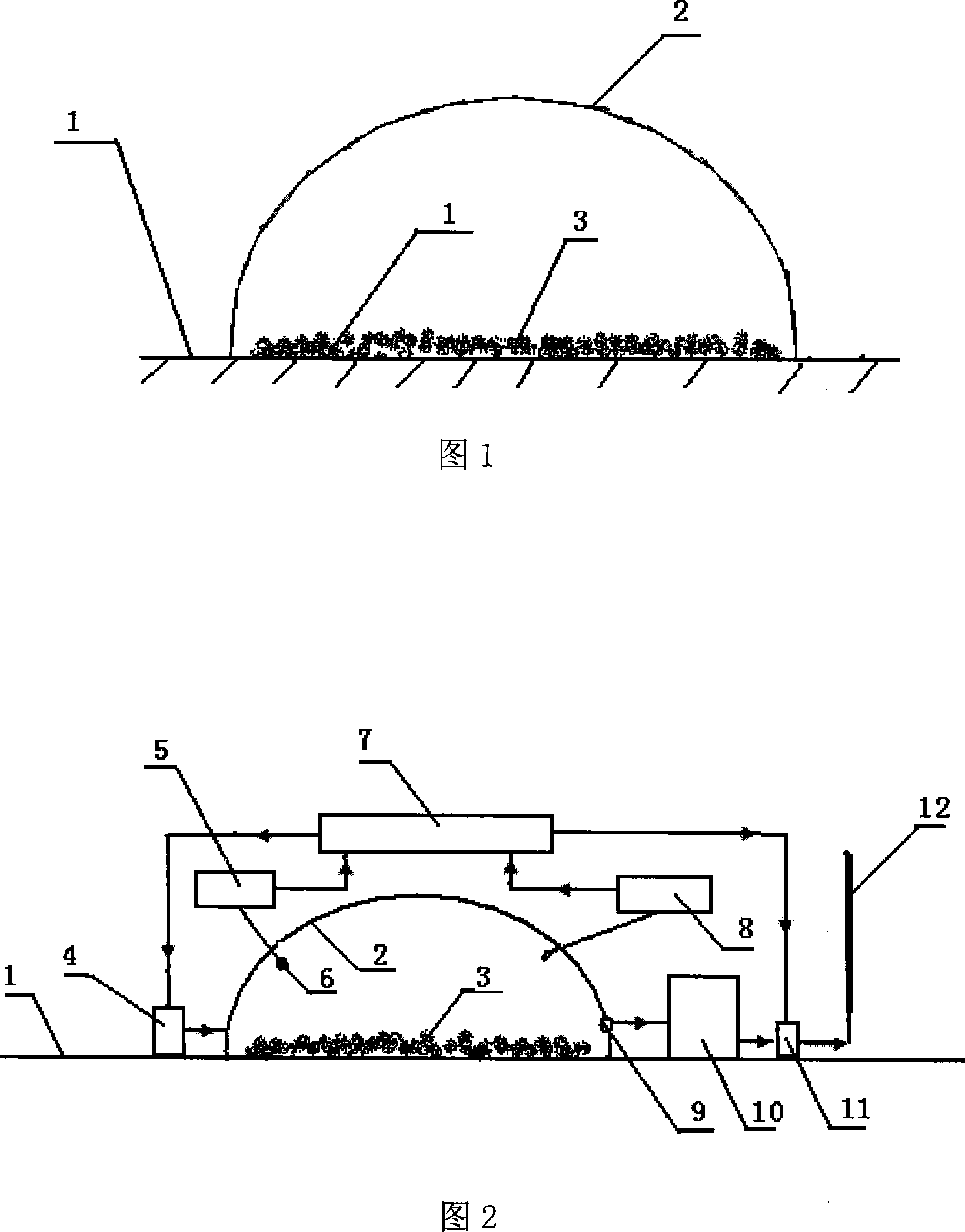

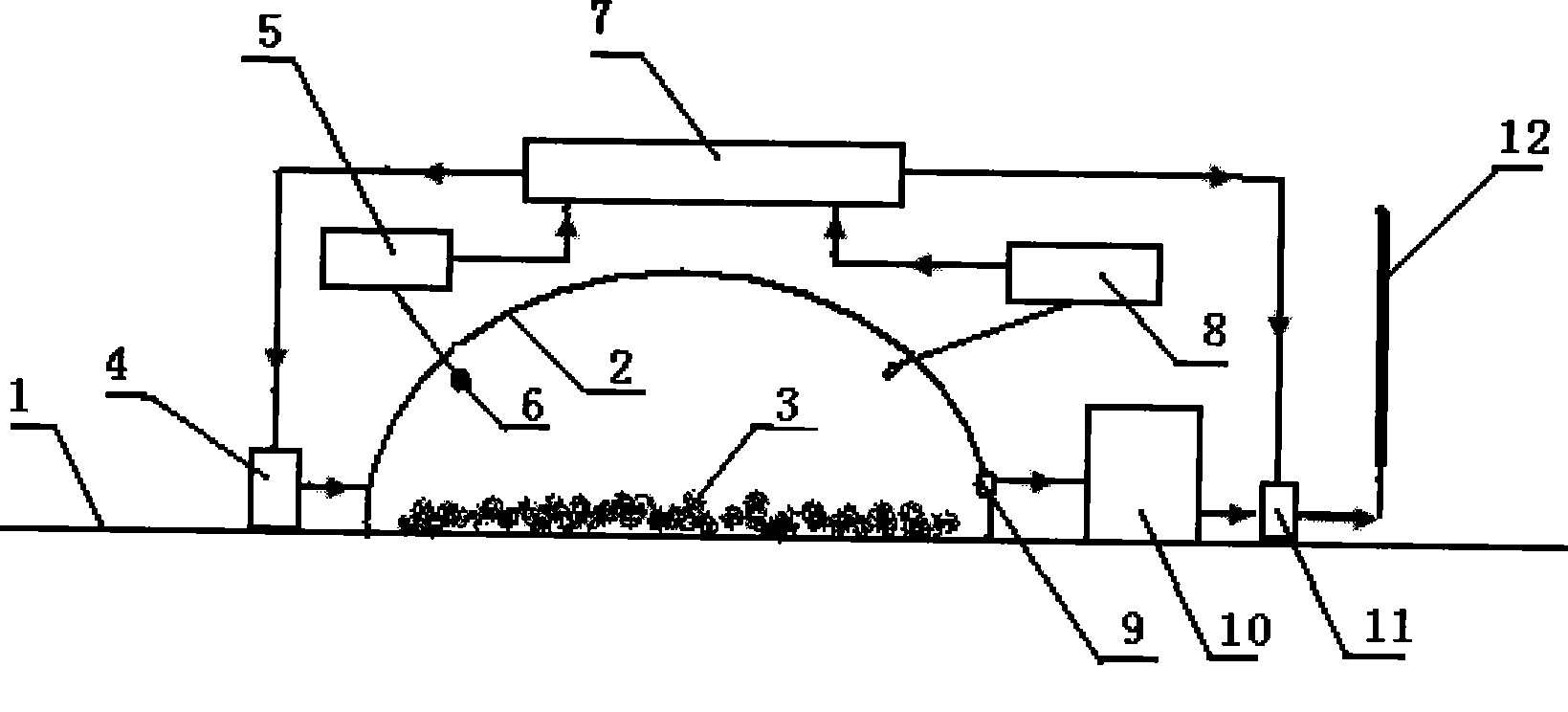

[0016] As shown in Figure 1-2, the malodorous gas treatment system of the garbage sanitary landfill according to the embodiment of the present invention includes an air-supported membrane structure 2, a blower fan 4, a pressure control device 5, a pressure sensor 6, and a computer terminal system 7 , monitoring system 8, automatic exhaust valve 9, gas treatment equipment 10, exhaust fan 11 and chimney 12; the edge of the air-supported membrane structure 2 is pre-buried in the landfill operation area 1 used to bury domestic waste 3 The steel support structure or foundation is connected, and the air-supported membrane structure 2 is guaranteed to be above the waste landfill operation area 1, so that the landfill operation of the waste landfill operation area 1 operates in an enclosed space; the monitoring system The sensor 8 is set in the air-supported membrane structure 2, the monitoring system 8, the blower fan 4, and the exhaust fan 11 are all connected to the computer termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com