Passive pin valve

A passive, needle valve technology, applied in the field of pressure injection molding equipment, can solve the problems of poor structural strength of the needle valve, decreased pressure transmission capacity, poor pressure transmission, etc., to improve work performance and service life, and improve strength and structural stability , The effect of improving the pressure transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

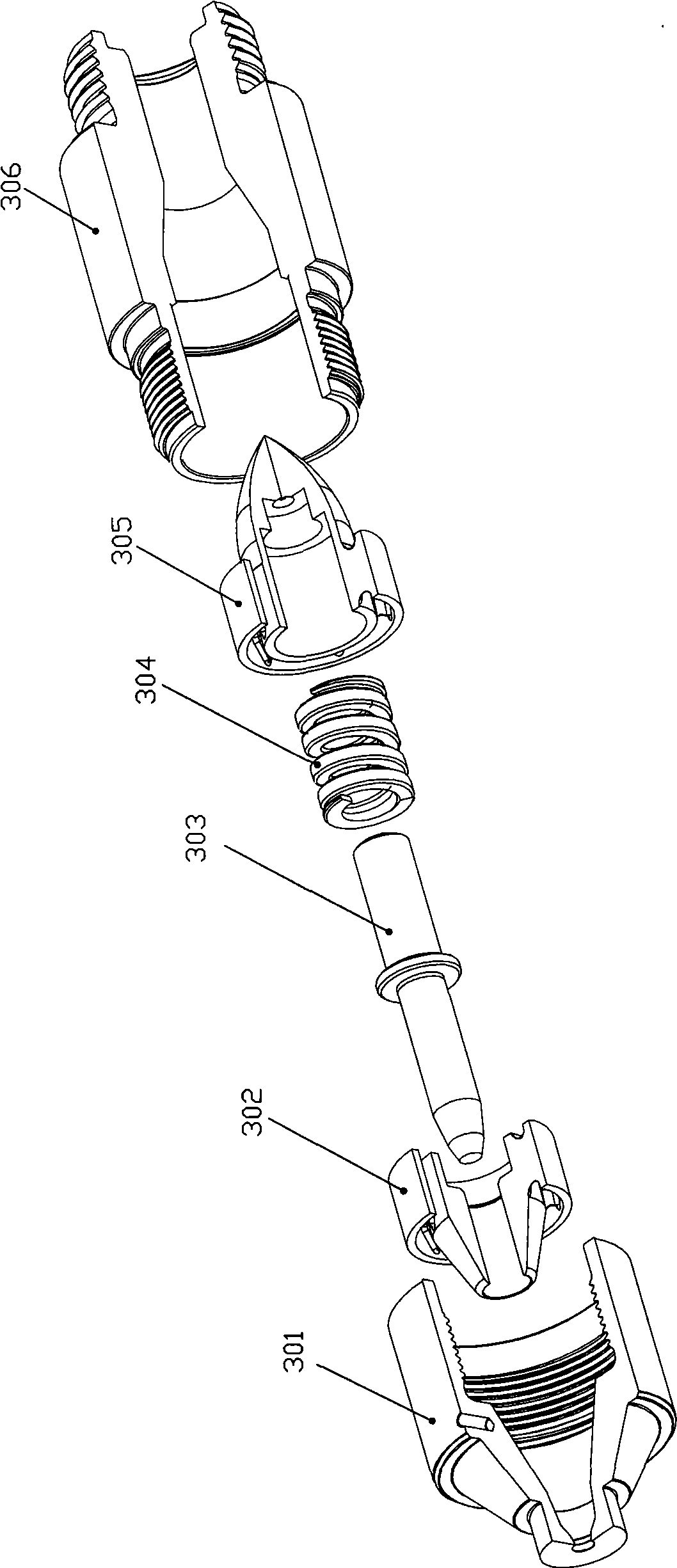

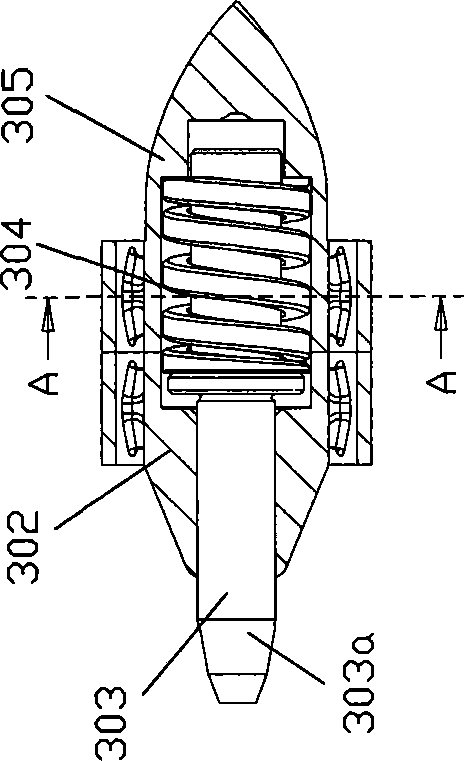

[0067] See Figure 5 ~ Figure 11b , The passive needle valve of the present invention includes a valve nozzle 1, one end of which is a cone with a central injection port 11, and the other end has a cavity structure 12; the first flow channel docking body 2 is installed in the valve nozzle 1 cavity In the body structure 12, a central through hole 21 corresponding to the central injection port 11 of the valve nozzle 1 is opened; and the first flow channel docking body 2 is also provided with three central through holes beside the central through hole 21 The sub-flow passages 22, 23, 24 that intersect with the 21 ports and communicate with the center injection port 11 of the valve nozzle are distributed symmetrically along the circumference of the center injection port 11 of the valve nozzle;

[0068] The second flow passage docking body 3, one end of which abuts against the first flow passage docking body 2 in the cavity structure 12 of the valve nozzle 1, and is threadedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com