Crawler crane

A technology of crawler crane and rotating frame, applied in the field of layout, can solve problems such as cost increase, and achieve the effects of improving transportability, easy operation, and reducing the radius of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiment which is a preferable form for carrying out this invention is demonstrated based on drawing.

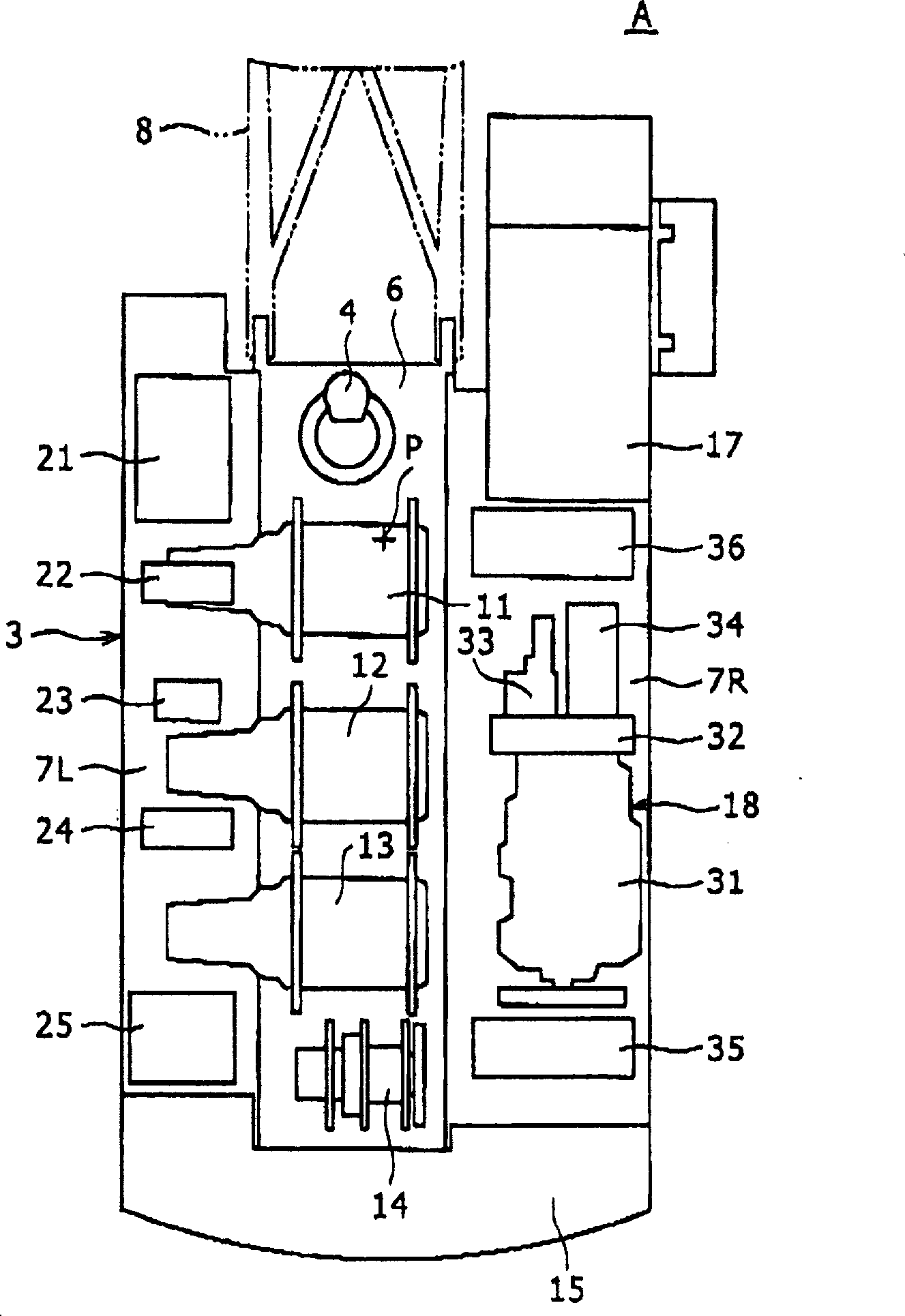

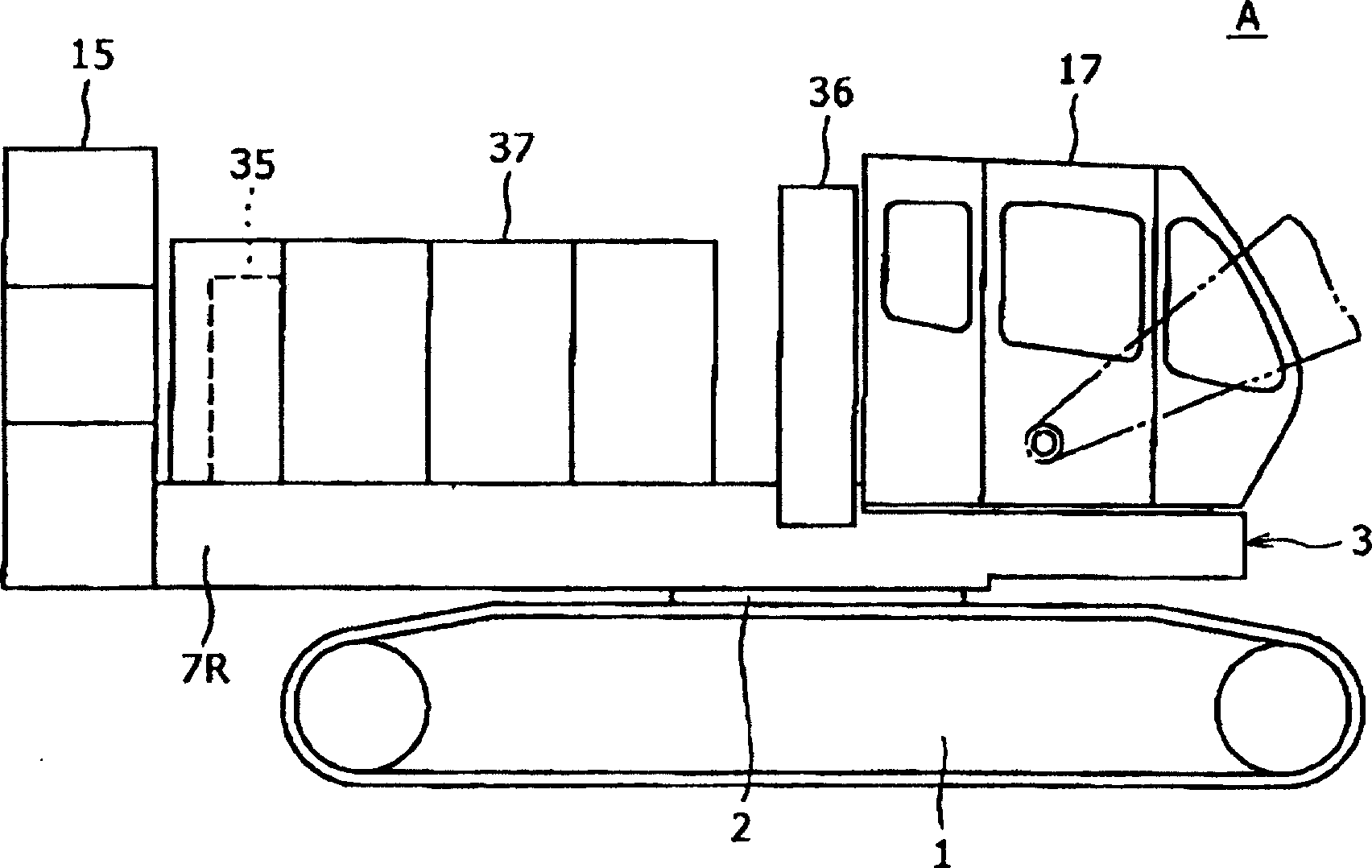

[0015] figure 1 and figure 2 The overall structure of the crawler crane A according to one embodiment of the present invention is shown. In this crawler crane A, a revolving upper body 3 is rotatably mounted on a traveling lower body 1 via a swivel device 2 . Although not shown in the figure, the rotating device 2 rotates the upper revolving body 3 around the rotation center point P by the operation of the revolving motor 4 .

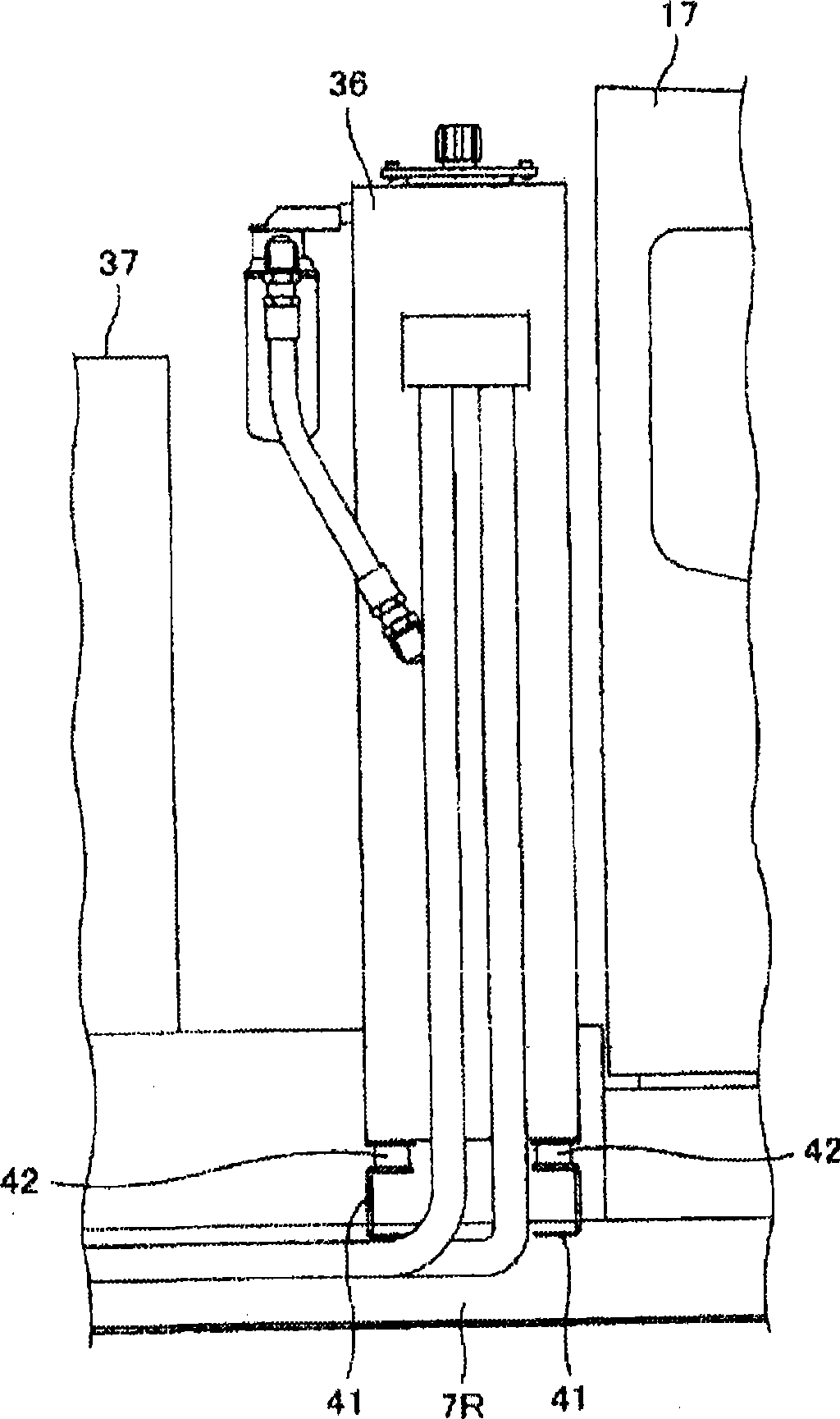

[0016] The revolving superstructure 3 includes, as its frame structure, a revolving frame 6 extending in the front-rear direction at a central portion, and left and right deck frames 7L, 7R respectively attached to left and right sides of the revolving frame 6 . On the front end of the rotating frame 6, the base end of the boom 8 is swingably supported. From the vicinity of the rotation center point P of the rotating frame 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com