Three-segment type silicon oil fan clutch

A clutch, three-stage technology, applied in the field of three-stage silicon oil fan clutch, can solve the problems of increasing the manufacturing cost and installation cost of the active plate, and achieve the effects of low noise, reasonable and simple overall structure, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

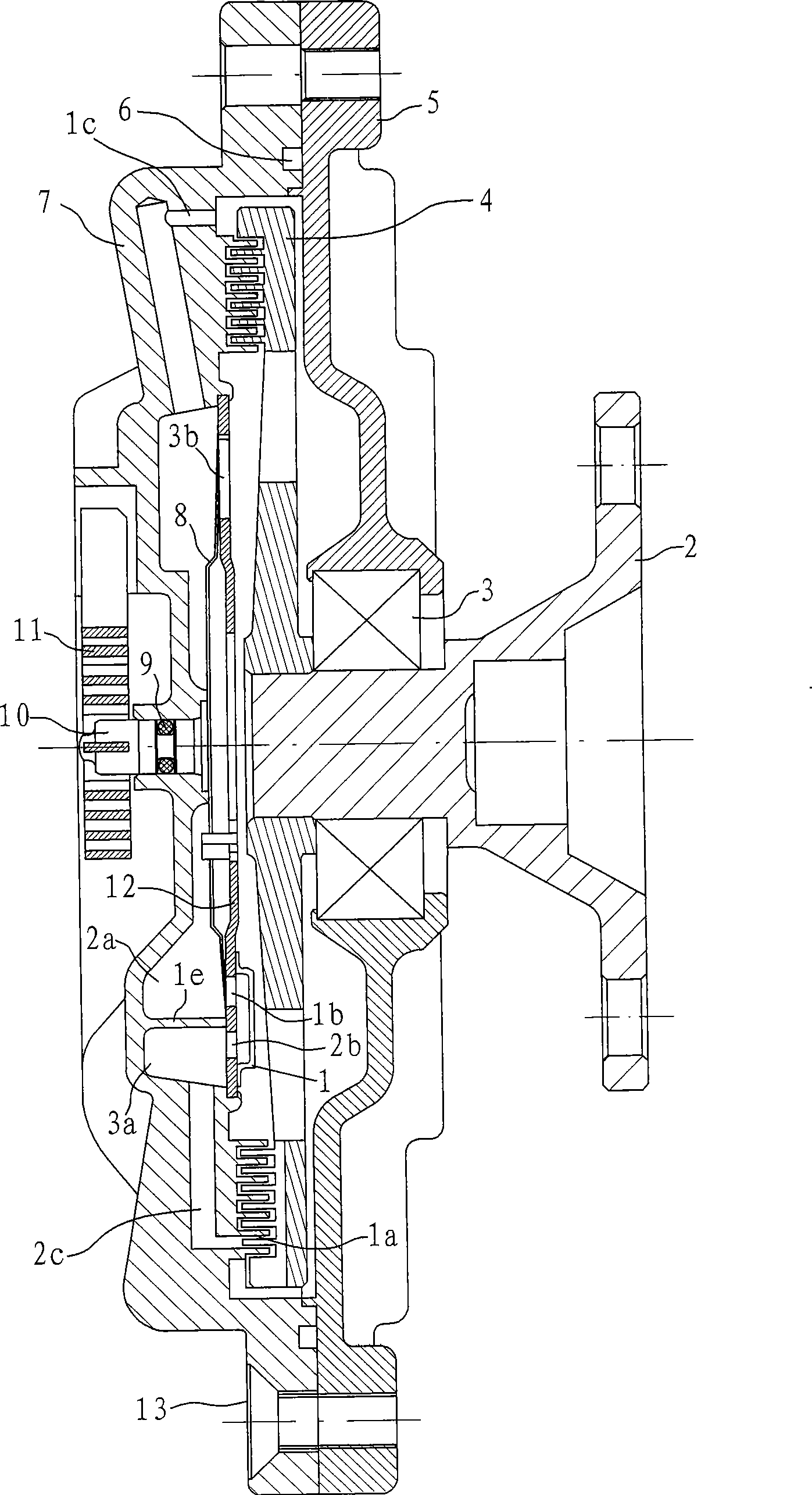

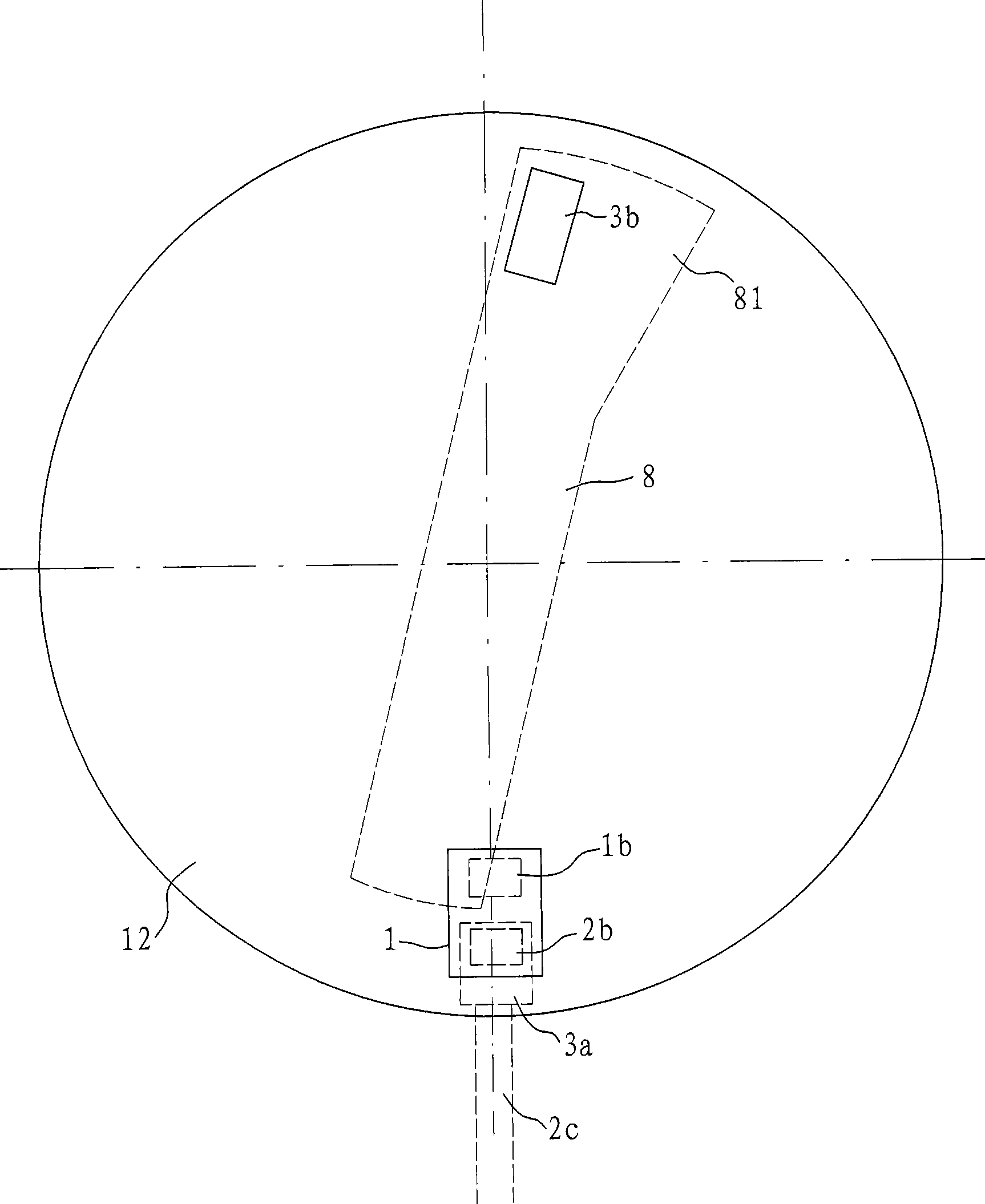

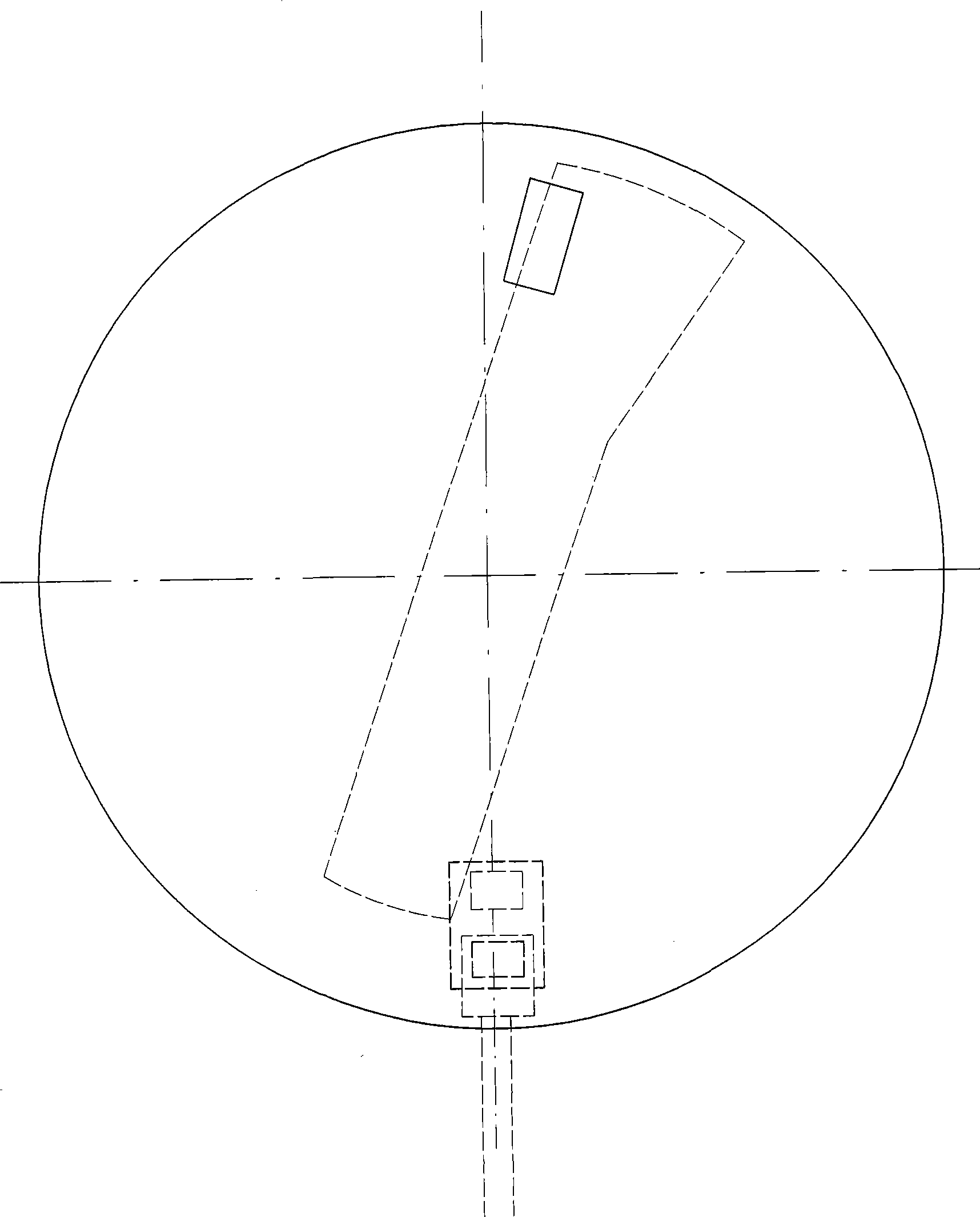

[0020] Example: Reference figure 1 As shown, the three-stage silicone oil fan clutch in this embodiment includes a housing 5, an oil storage cover 12, a temperature sensing ring 11, a front cover 7, a driving shaft 2 and a driving plate 4, and the housing 5 is arranged on the driving shaft through a bearing 3 2, the driving plate 4 is arranged on the driving shaft 2, and the sealing ring 6 is used to realize the sealing connection between the front cover 7 and the housing 5, and the screw 13 is used to connect and fix it.

[0021] The oil storage cover 12 is arranged at the rear end of the front cover 7 and forms an oil storage cavity with the front cover 7, and an engagement cavity 1a is formed between the active plate 4, the front cover 7 and the housing 5, and the oil storage cavity and the engagement cavity 1a It has an oil return passage 1c and an oil outlet passage 2c, both of which in this embodiment are set on the front cover 7 .

[0022] The oil storage cover 12 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com