Adjustable automatic wave amplitude gain compensation method and circuit for ultrasonic thickness gauge

A technology of automatic gain compensation and ultrasonic thickness gauge, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of slow response speed and poor automaticity, and achieve fast response speed, high automaticity, and application reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment of the present invention provides an adjustable amplitude automatic gain compensation method for an ultrasonic thickness gauge. The adjustable amplitude automatic gain compensation method for an ultrasonic thickness gauge according to the present invention will be described in detail below with reference to FIG. 8 a , FIG. 8 b and FIG. 9 .

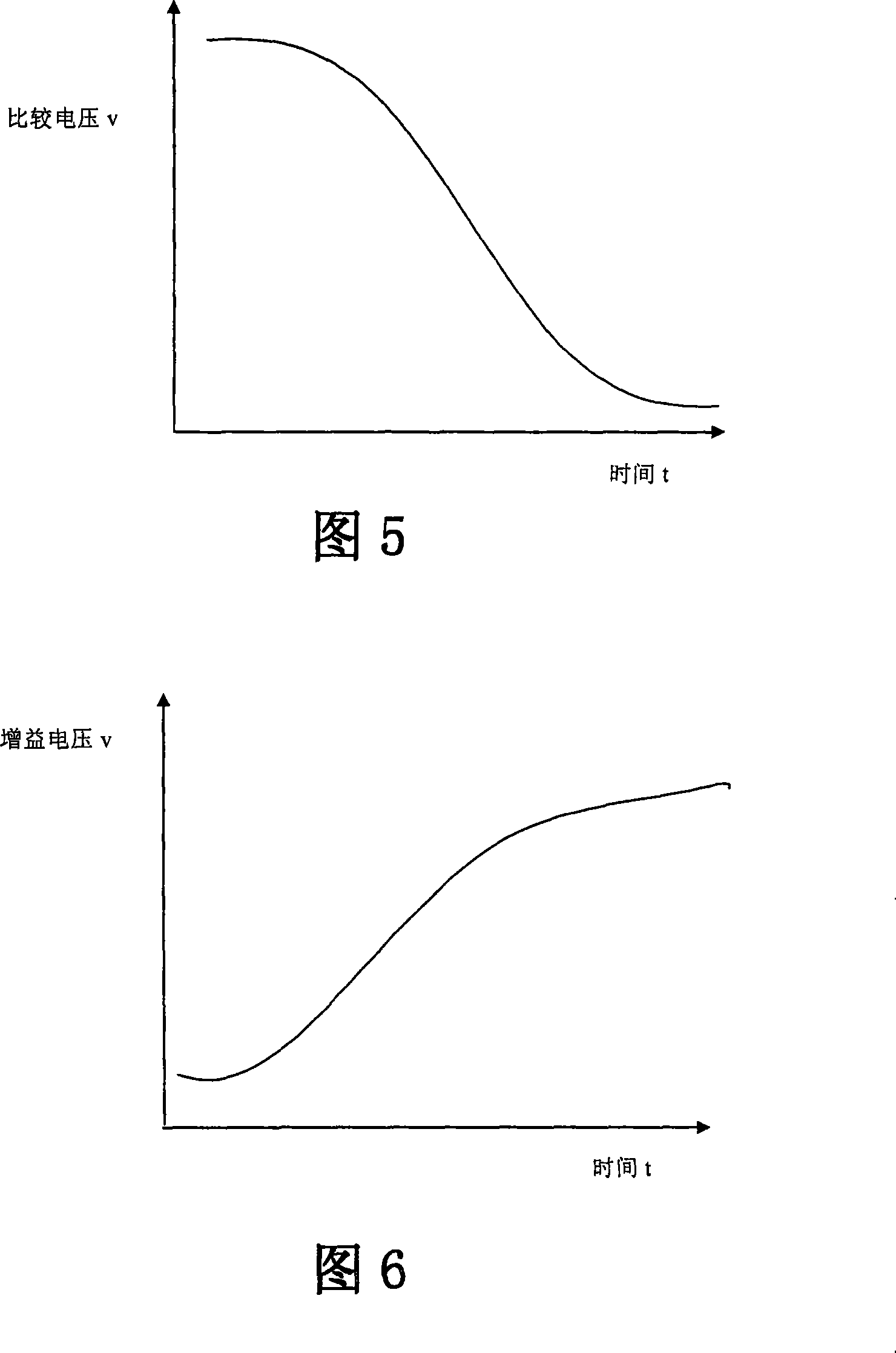

[0045] First, set a fixed gain voltage; then, using the influence of the ultrasonic transmission distance, the longer the ultrasonic transmission distance, the smaller the echo amplitude, the triangular voltage is generated by the integrating circuit within the ultrasonic transmission time, and the triangular voltage is converted by the adder The voltage and the gain voltage are superimposed together to realize automatic amplitude compensation for ultrasonic thickness measurement. Please refer to Figure 8a for the basic and specific circuit design, and refer to Figure 8b for the compensated control gain of the amplitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com