Optical device containing refrigeration chip

A technology for cooling chips and light-emitting devices, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as reduced benefits, damaged components, and impacted benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

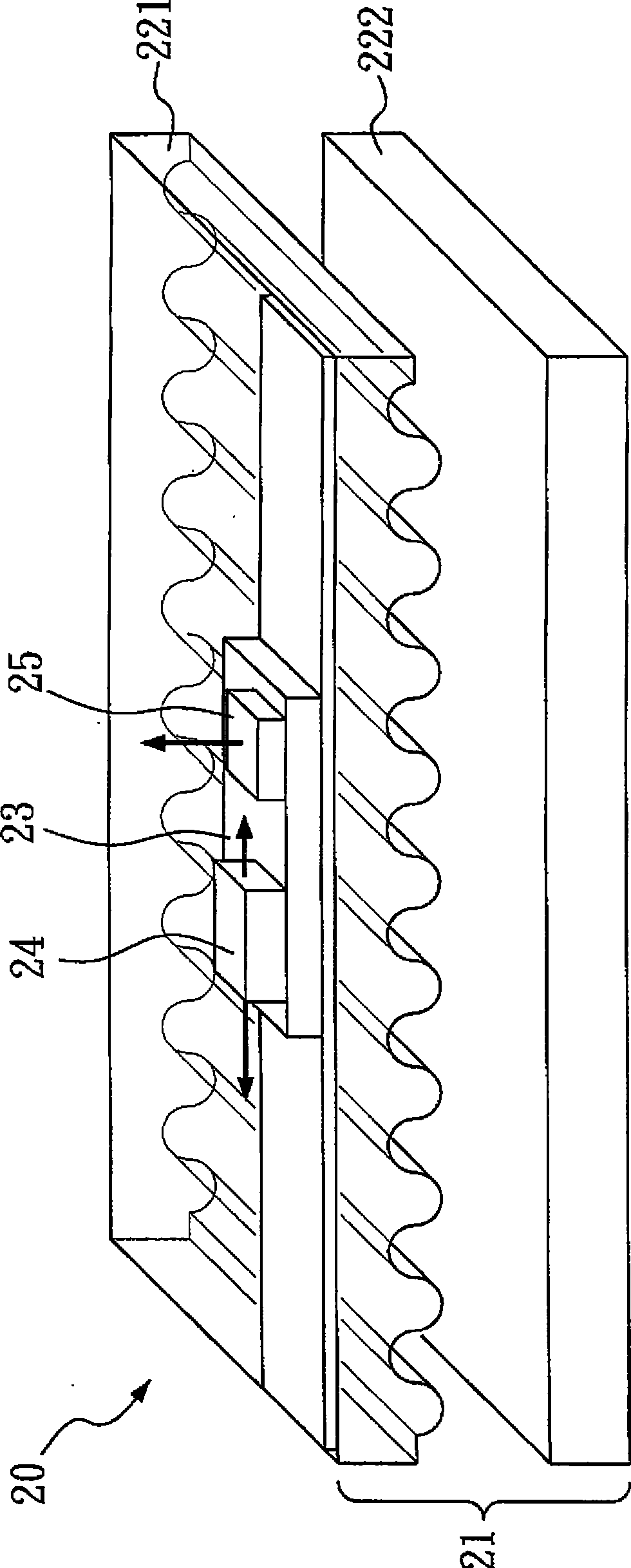

[0015] According to a preferred embodiment of the light-emitting device of the present invention, it may include a main base, and the main base includes a cooling chip, and each side of the cooling chip has a substrate, at least one of which is There is a submount on the substrate, and the submount has one or more light emitting diode chips and one or more laser diode chips.

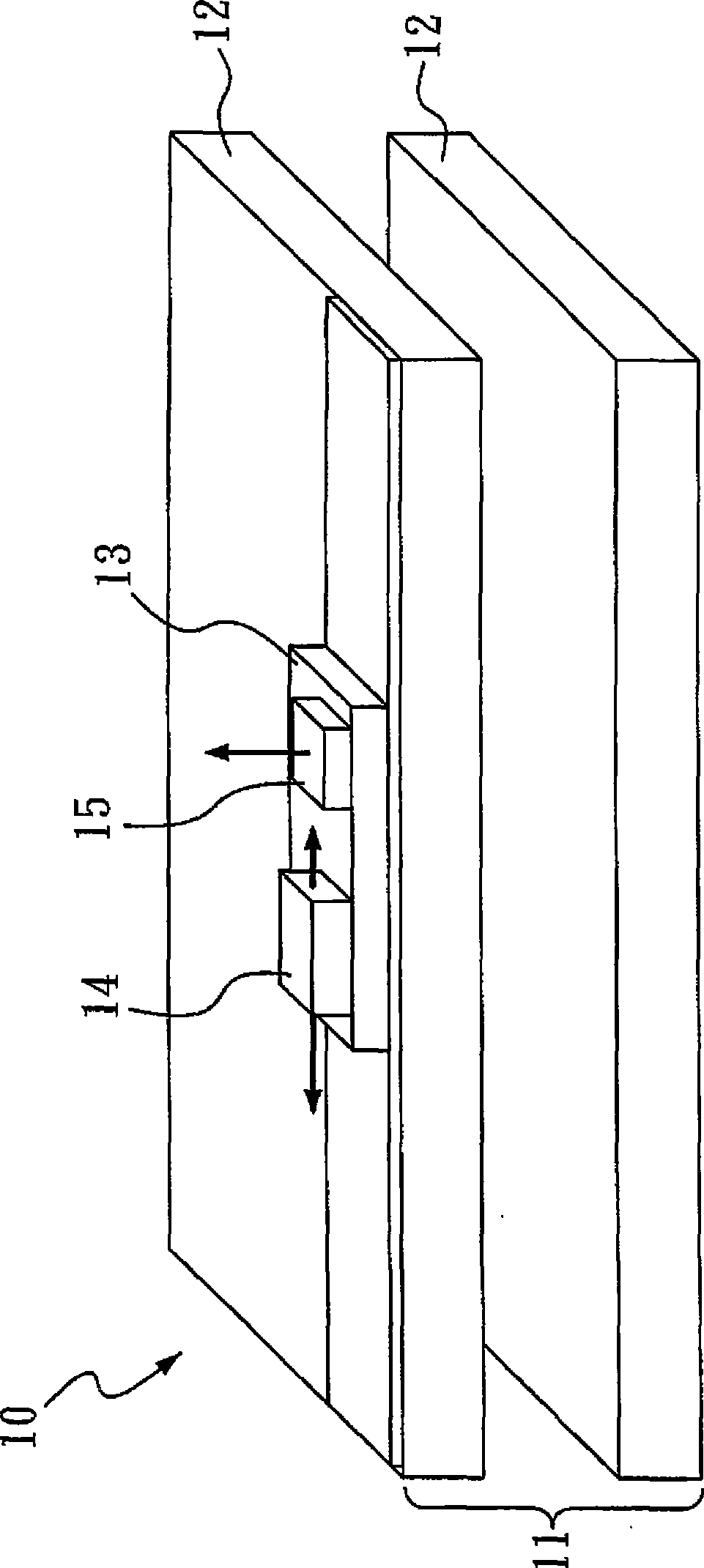

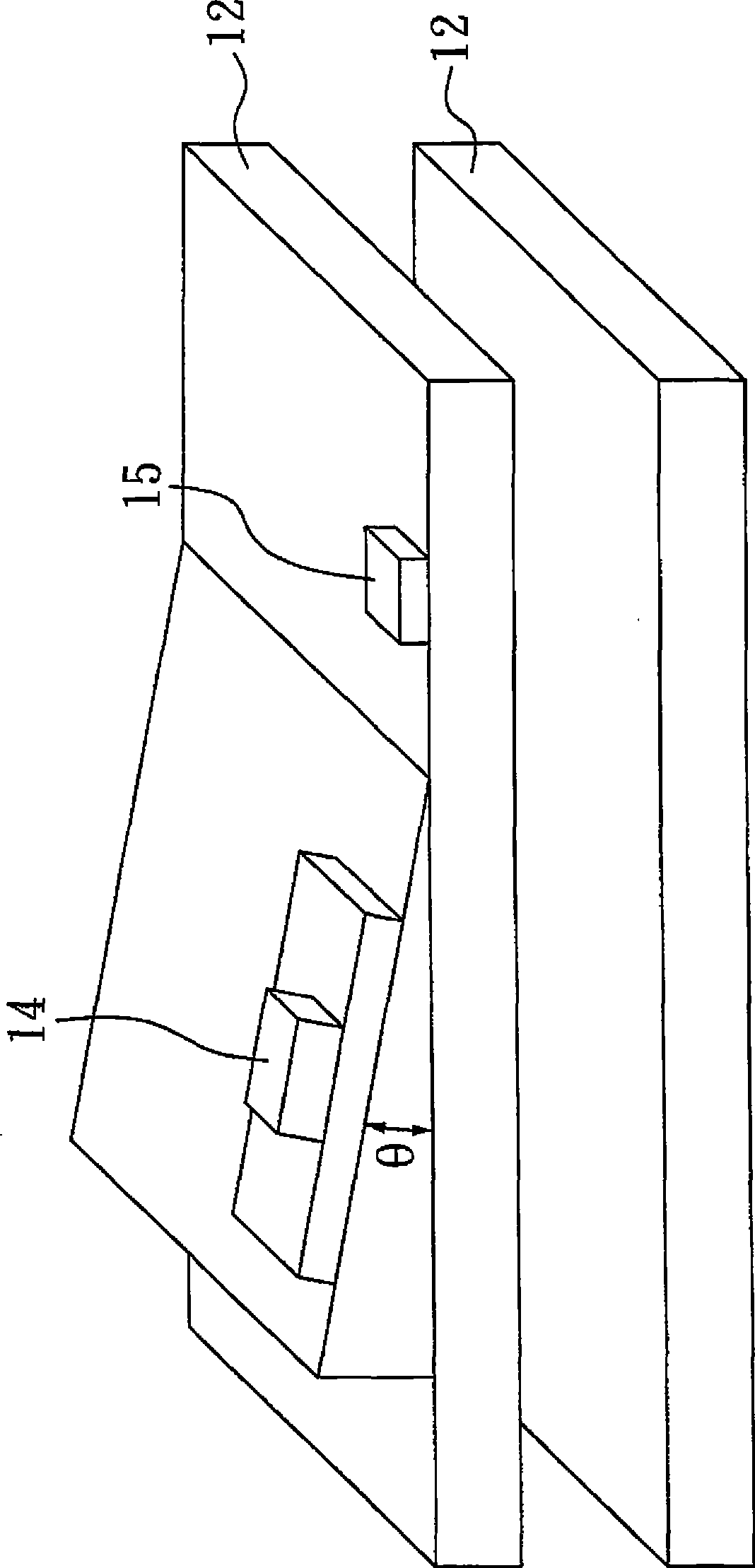

[0016] figure 1 Shown is the first embodiment, the light-emitting device 10 has a cooling chip (TE cooler) 11 on the light-emitting device, a substrate 12 is provided on both sides of the cooling chip, and a substrate 12 is provided on one side of the cooling chip. One or more sub-bases 13 are connected with the laser diode chip 14 and the light emitting diode chip 15, that is, the laser diode chip 14 and the light emitting diode chip 15 are arranged on the cooling chip, so that the laser diode chip 14 and the light emitting diode chip 15 The heat dissipation path is the same.

[0017] The material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com