A kind of nano-polishing liquid, polishing paste and preparation method thereof

A technology of polishing liquid and polishing paste, which is applied in the direction of polishing compositions containing abrasives, etc., which can solve the problems of low light sensitivity of stone materials, low surface wear resistance, cumbersome use of polishing products and technologies, etc., and achieve high clarity , good brightness, not easy to scratch the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention adopts nanocomposite technology, and utilizes nanometer inorganic materials and macromolecular polymer materials to produce novel high-tech nanometer polishing liquid.

[0035] The principle is that under the action of pressure and friction, nanoparticles use the physical and chemical reactions of covalent bonding of molecular bonds to crystallize and arrange on the surface of natural marble and artificial marble, thus forming a layer of clear, dense and hard nano protective film. . The film has the function of fully filling the pores and microcracks on the surface of natural marble and artificial marble, and can change the microstructure of the original natural marble and artificial marble surface, making the surface of natural marble and artificial marble become Smoother and more uniform, it promotes the light reflection on the stone surface from diffuse reflection to total reflection, so as to achieve a mirror effect and make the stone surface transpare...

no. 1 example

[0036] For this reason, according to the first embodiment of the present invention, a kind of preparation method of nano-polishing liquid is provided, and this nano-polishing liquid is mainly used in the polishing of marble plate, and specific steps comprise:

[0037] Step 1: Add large particle size organosilicon nano solution and large particle size silica sol into purified water;

[0038] In this step, two kinds of large-diameter organosilicon nano-solutions are selected, which are respectively large-particle-diameter organosilicon nano-solution A and large-particle-diameter organosilicon nano-solution B, and the particle diameters of the organosilicon are between 40-60 nm. Between and between 90-130nm.

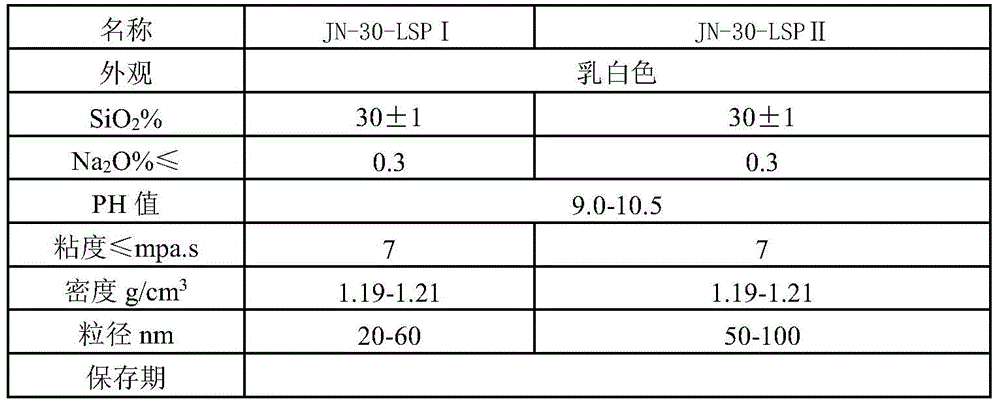

[0039] Further, the large particle size silica sol is silicon oxide silica sol, and its molecular formula is expressed as mSiO 2 ·nH 2 O, with a diameter of 10-100nm.

[0040] Step 2: Differentiate with a disperser to completely dissolve in water;

[0041] Step 3: Add t...

Embodiment 2

[0048] According to one embodiment of the present invention, the preparation method of the above nano-polishing liquid is as follows:

[0049] Step 1: Add large particle size organosilicon nano solution and large particle size silica sol into purified water;

[0050] Among them, calculated in parts by weight, the large particle size organosilicon nano solution A: 40-60nm accounts for 15-22; the large particle size organosilicon nano solution B: 90-130nm accounts for 32-39. Cracks make the surface of the stone more smooth and uniform, and promote the light reflection on the surface of the stone to approach total reflection from diffuse reflection. In the embodiment, the large particle size organic silicon nano solution produced by Laiyang Shengbang Organic Silicon Technology Co., Ltd. is selected. .

[0051] The large particle size silica sol is silica silica sol, and its molecular formula is expressed as mSiO 2 ·nH 2 O has a diameter of 10-100nm, and its parts by weight acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com