Display device and production method for pixel forming structure of organic electronic assembly

A technology of organic electronics and a manufacturing method, which is applied in the field of manufacturing the pixel formation structure of displays and organic electronic components, and can solve the problems of shrinking pixel display area 13, uneven light emission of the display, insufficient light emission brightness of the display, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

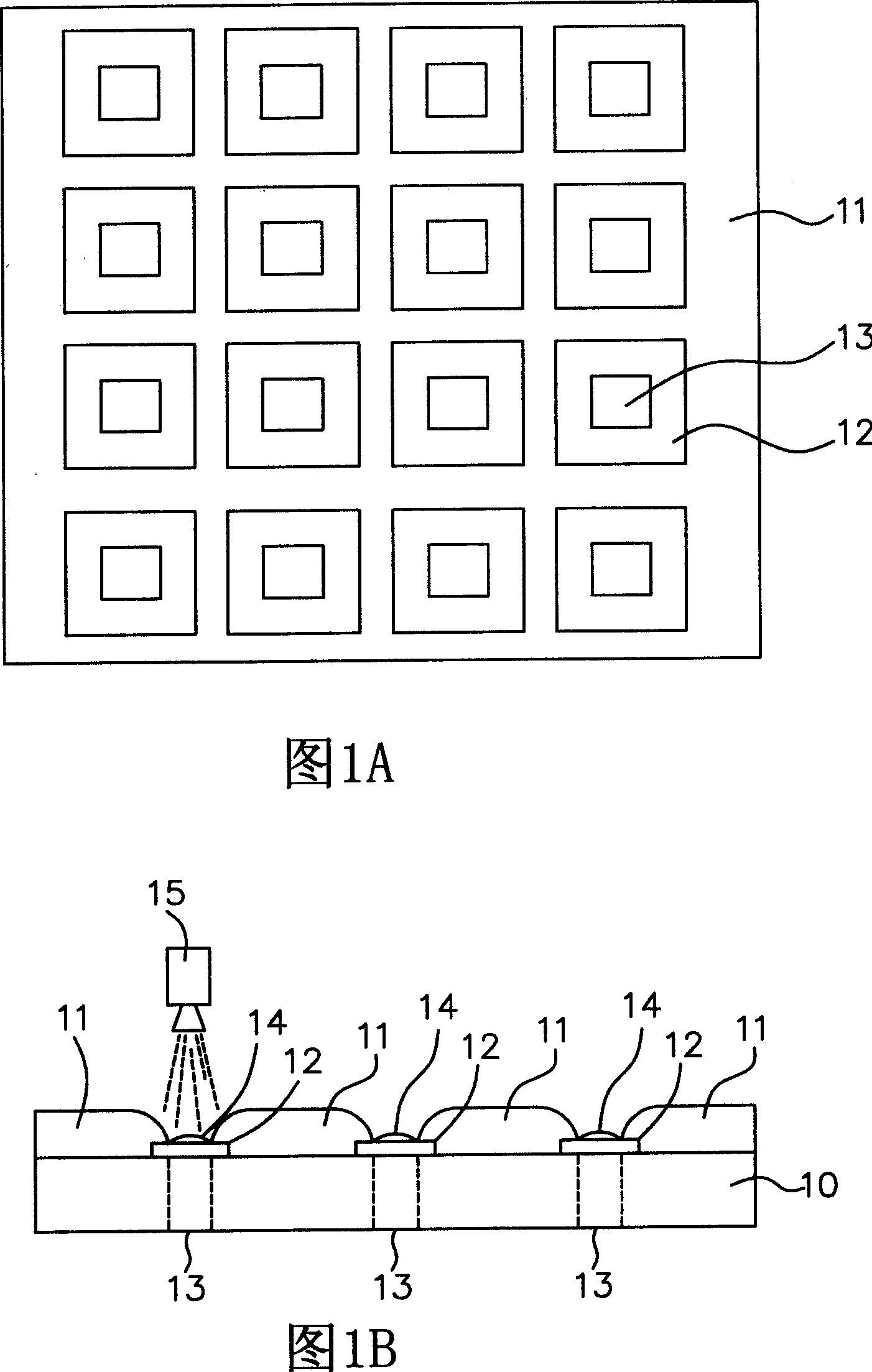

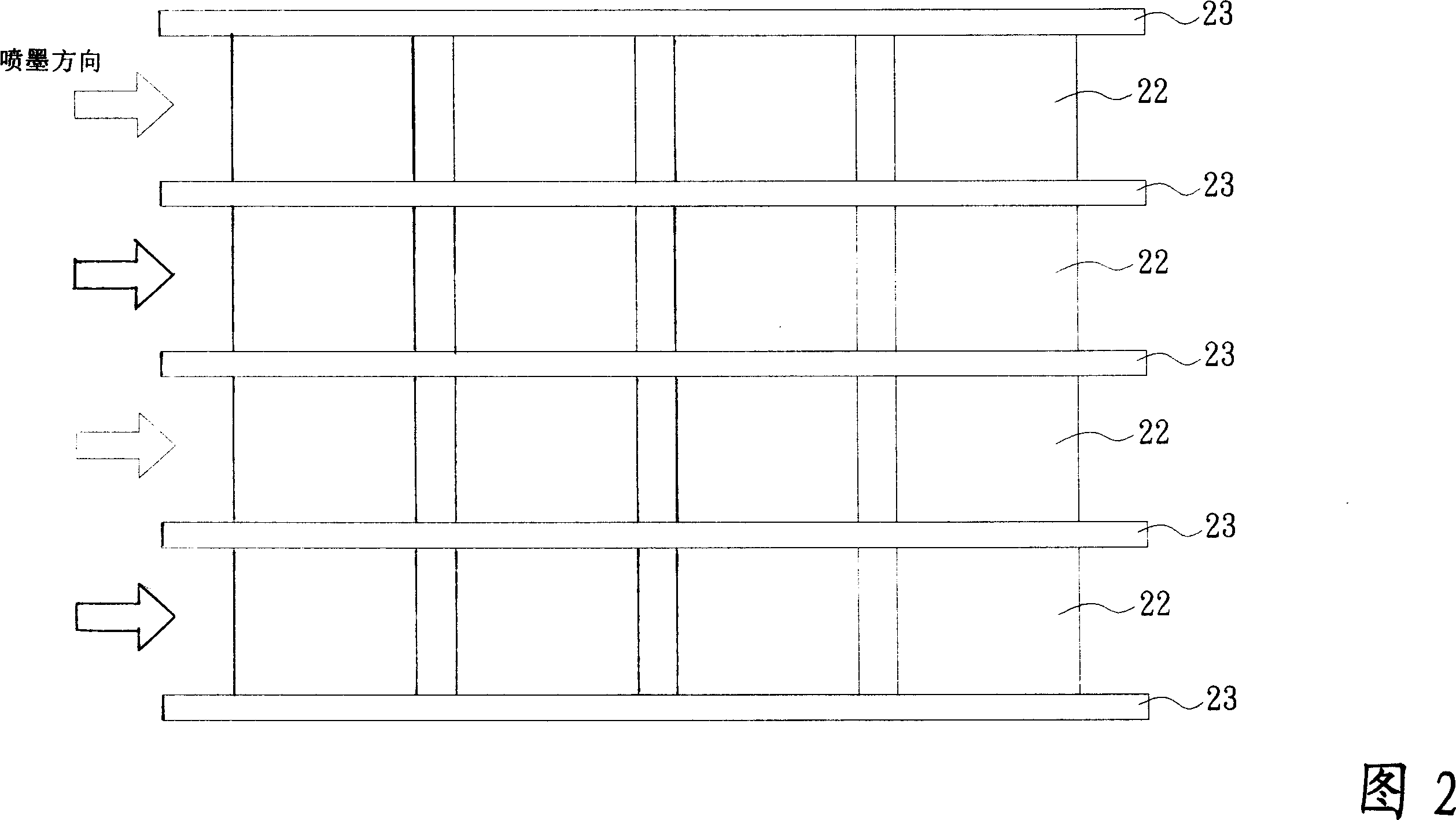

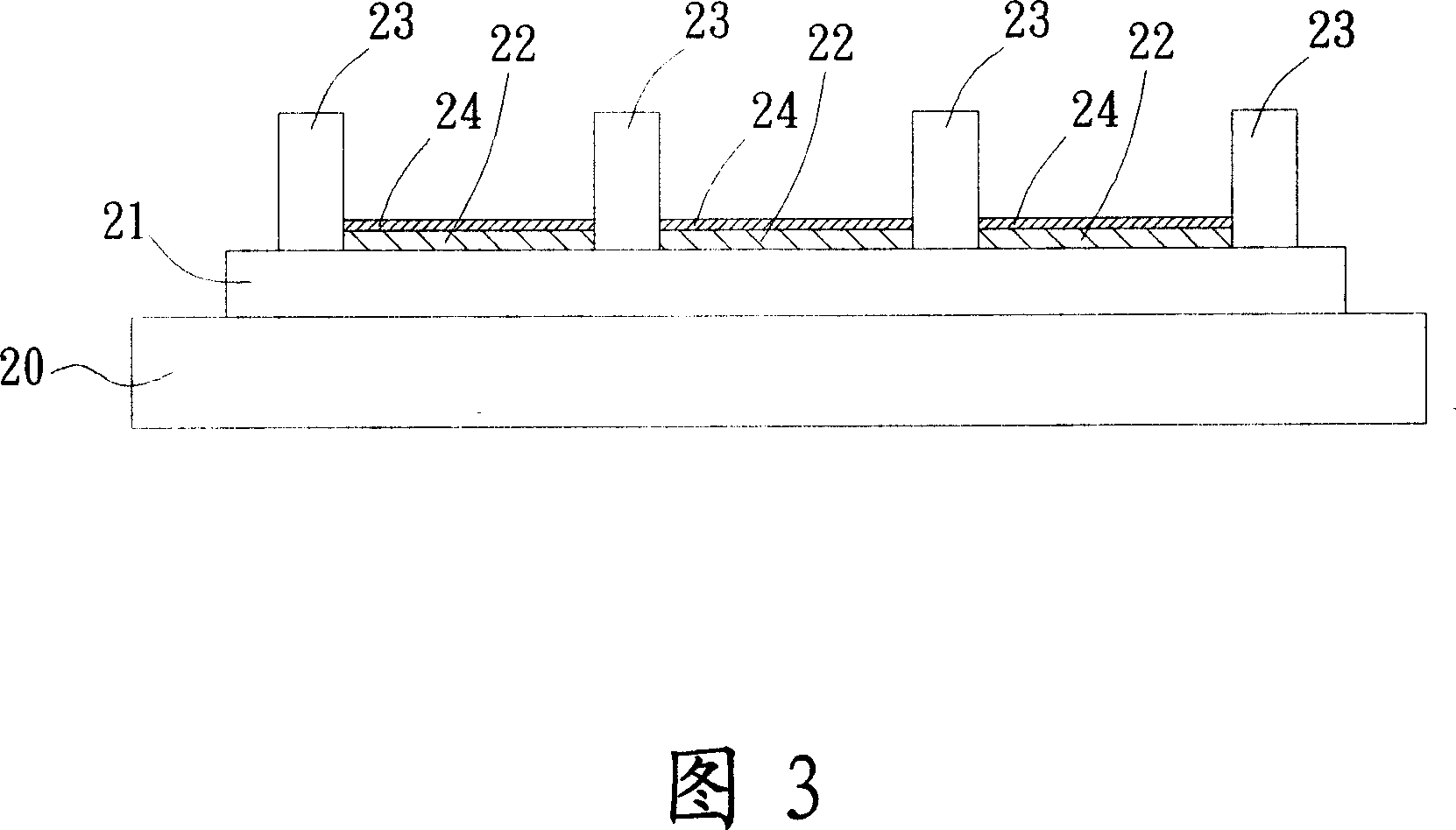

[0021] Please refer to Fig. 1 and Fig. 3, which are schematic diagrams of the pixel formation structure of the display of the present invention, wherein the light source of the display is composed of a polymer light-emitting diode (Polymer OLED, PLED), and the display has the characteristics of active light emission. It is very suitable as a light-emitting display panel for a display, and has the advantages of power saving and good brightness. At the same time, the manufacturing process of the present invention is not limited to the manufacturing process of the display, and also includes, for example, the manufacturing process of organic electronic components (Organic Electronic). Applicable technical means of the present invention, this technical means is to use insulating material (Bank) 23 to arrange liquid ink with single vertical or horizontal direction on the two peripheries parallel to picture element (Pixel) 22 in the manufacturing process, and this insulating material 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com