Method for preparing polymer emulsion of optical anode of dye sensitization battery

A dye-sensitized battery and polymer emulsion technology, which is applied in the field of dye-sensitized solar cell materials, can solve the problems that fossil energy cannot meet the long-term needs of human beings, and achieve the effect of improving photoelectric conversion efficiency and increasing short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

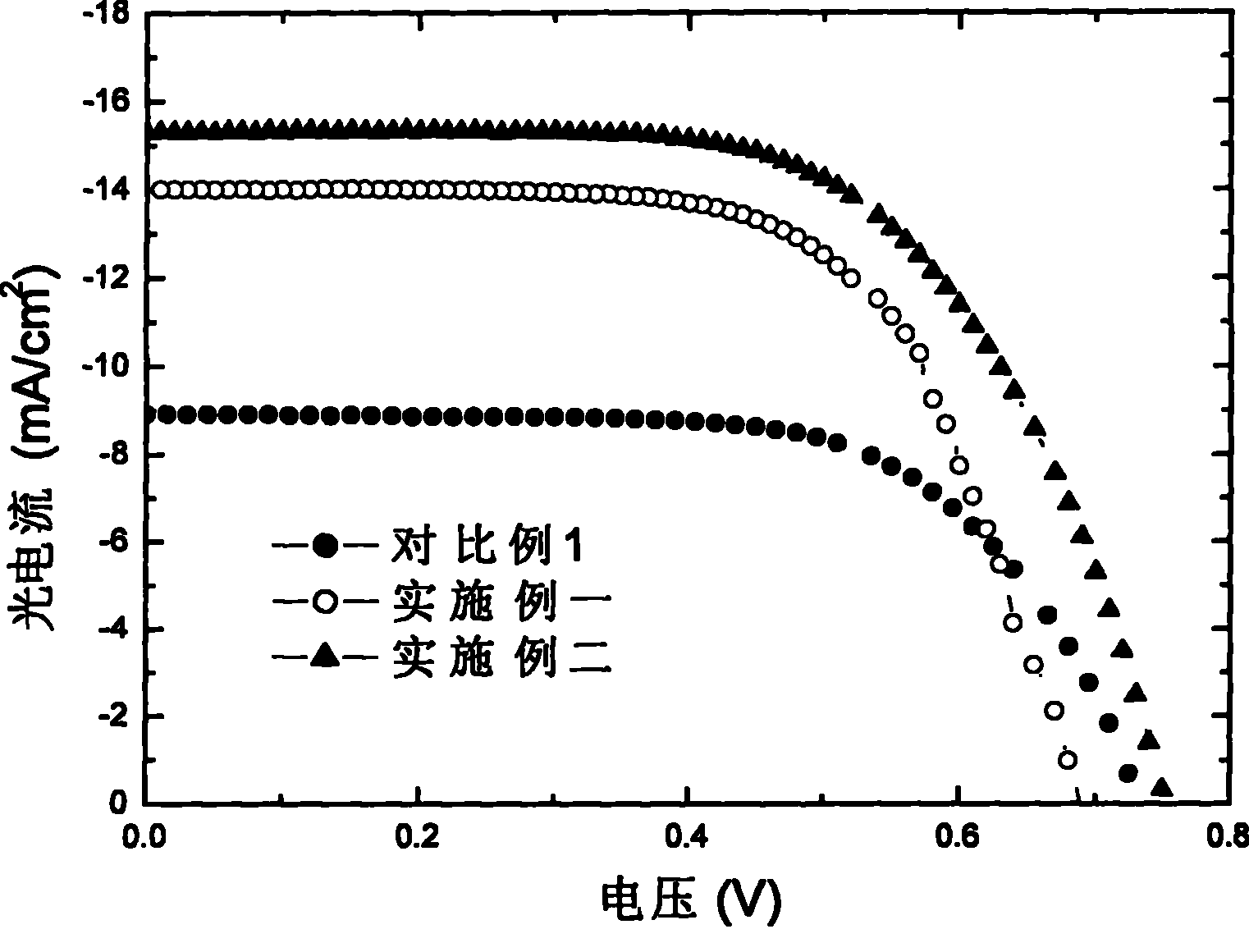

[0027] This embodiment is an experiment of preparing a device by using a polymer sol.

[0028] The polymer sol, including 2.6 grams of TiO2 (particle diameter 21nm), 7ml styrene and butyl acrylate copolymer emulsion (molar ratio is 1: 1, solid content 50%, emulsion particle diameter is 100nm), 10ml water, in conductive Scratch the film on the glass, and then sinter at 450°C for 30 minutes. After the temperature is cooled to about 100°C, put the electrode piece into 5mM N3 / ethanol solution and soak for 12 hours, take it out and rinse it with absolute ethanol, dry it, and use a standard Solid electrolyte, platinum-coated conductive glass as a counter electrode, assembled into a battery. Under the simulated sunlight irradiation of 30mW / cm2, the measured open circuit voltage of the battery is 0.69V, the short circuit current is 3.50mA / cm2, the fill factor is 0.64, and the total photoelectric conversion efficiency is 5.2%.

Embodiment 2

[0030] This embodiment is an experiment of using polymer sol and adding admixtures to improve film formation and prepare devices.

[0031] With polymer sol, comprise 3.6 gram TiO2 (particle diameter 21nm), 7ml styrene and butyl acrylate (molar ratio is 1: 1) copolymer emulsion (solid content 57%, emulsion particle diameter is 300nm), 20ml water, 0.46ml Triton, scratch the film on the conductive glass, and then sinter at 450°C for 30 minutes. After the temperature is cooled to about 100°C, soak the electrode piece in 5mM N3 / ethanol solution for 12 hours, take it out with anhydrous Rinse with ethanol, dry in the air, use quasi-solid electrolyte, platinum-plated conductive glass as the counter electrode, and assemble into a battery. Under the simulated sunlight irradiation of 30mW / cm2, the measured open-circuit voltage of the battery is 0.75V, the short-circuit current is 3.8mA / cm2, the fill factor is 0.63, and the total photoelectric conversion efficiency is 6.0%.

Embodiment 3

[0033] This example is an experiment to verify the stability of the polymer sol.

[0034] The polymer sol in Example 2 remained unchanged in its apparent state after standing for one month, and was still a viscous white emulsion. Scraping the film in this way, the efficiency obtained by preparing the battery is basically the same as that of the battery in Example 2, wherein the open circuit voltage is 0.59V, the short circuit current is 5.2mA / cm2, the fill factor is 0.69, and the total photoelectric conversion efficiency is 5.4%. This example shows that the stability of the polymer sol is very good, and the film formation after standing for a period of time will not affect the efficiency of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com