Spinning machine

A spinning machine and frame technology, applied in the field of spinning machines, to achieve high cost performance, reduced longitudinal stroke, and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

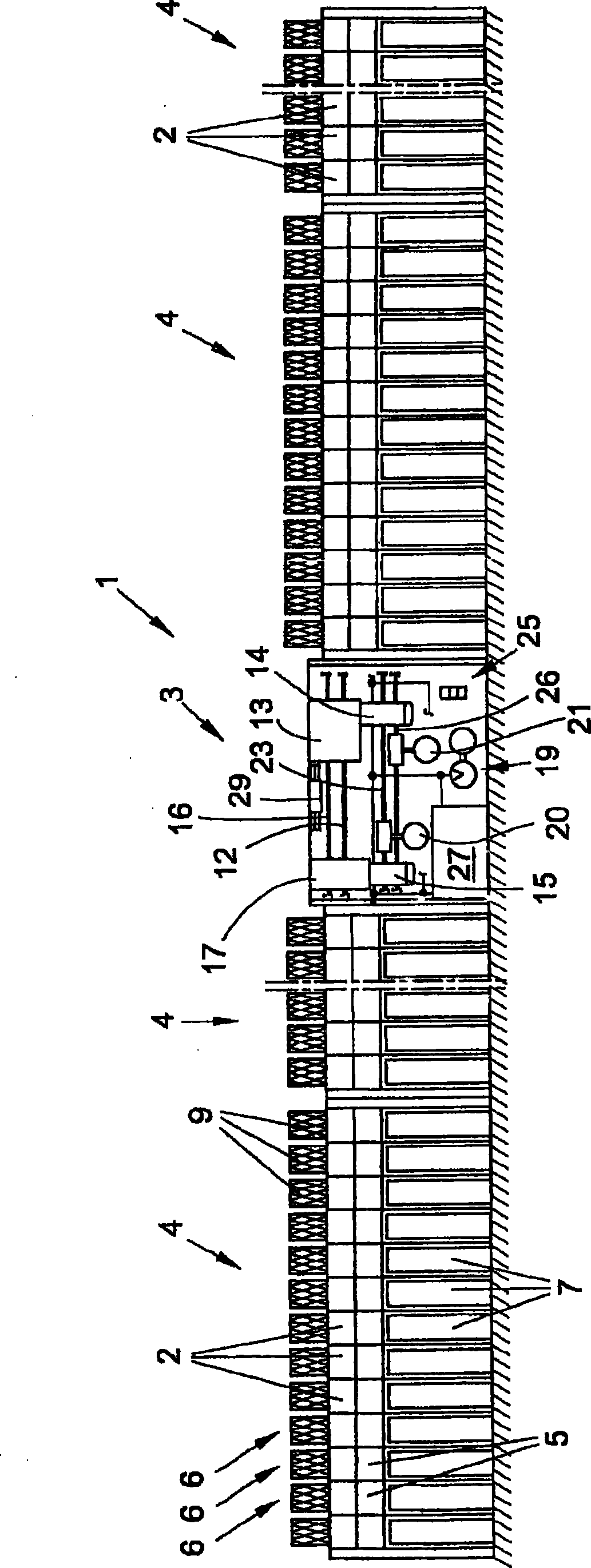

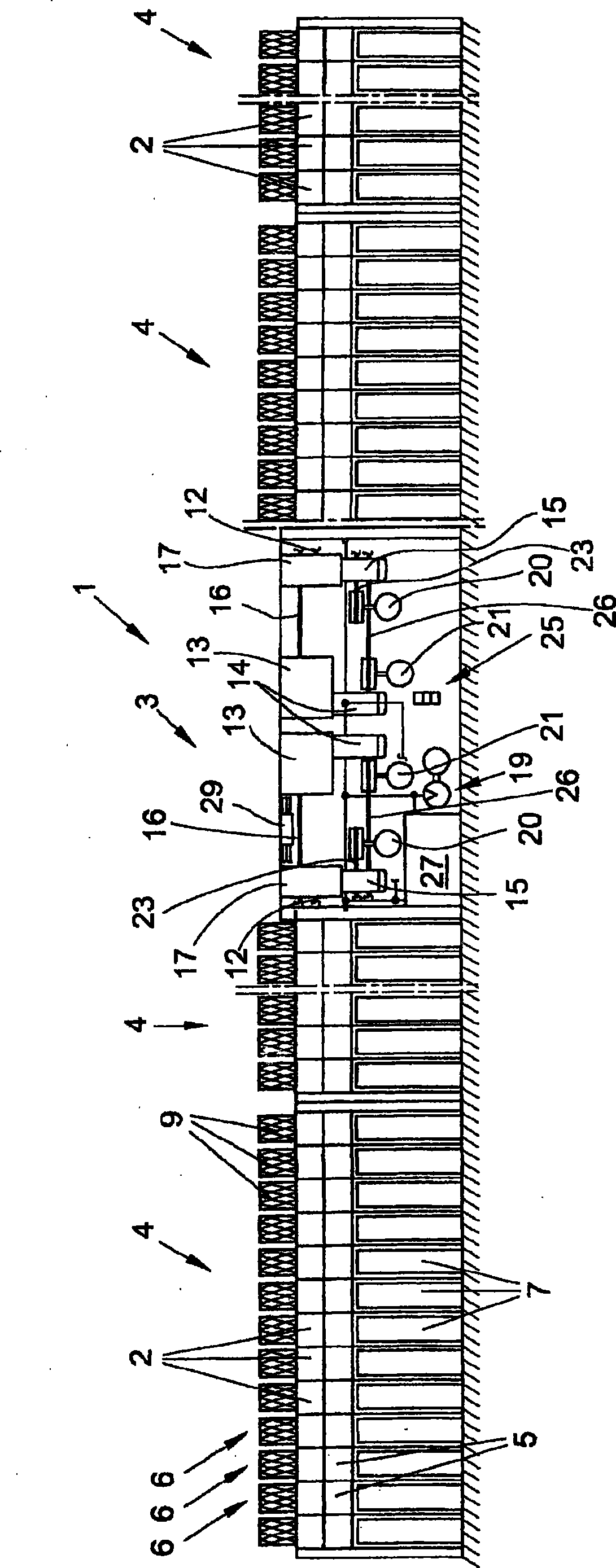

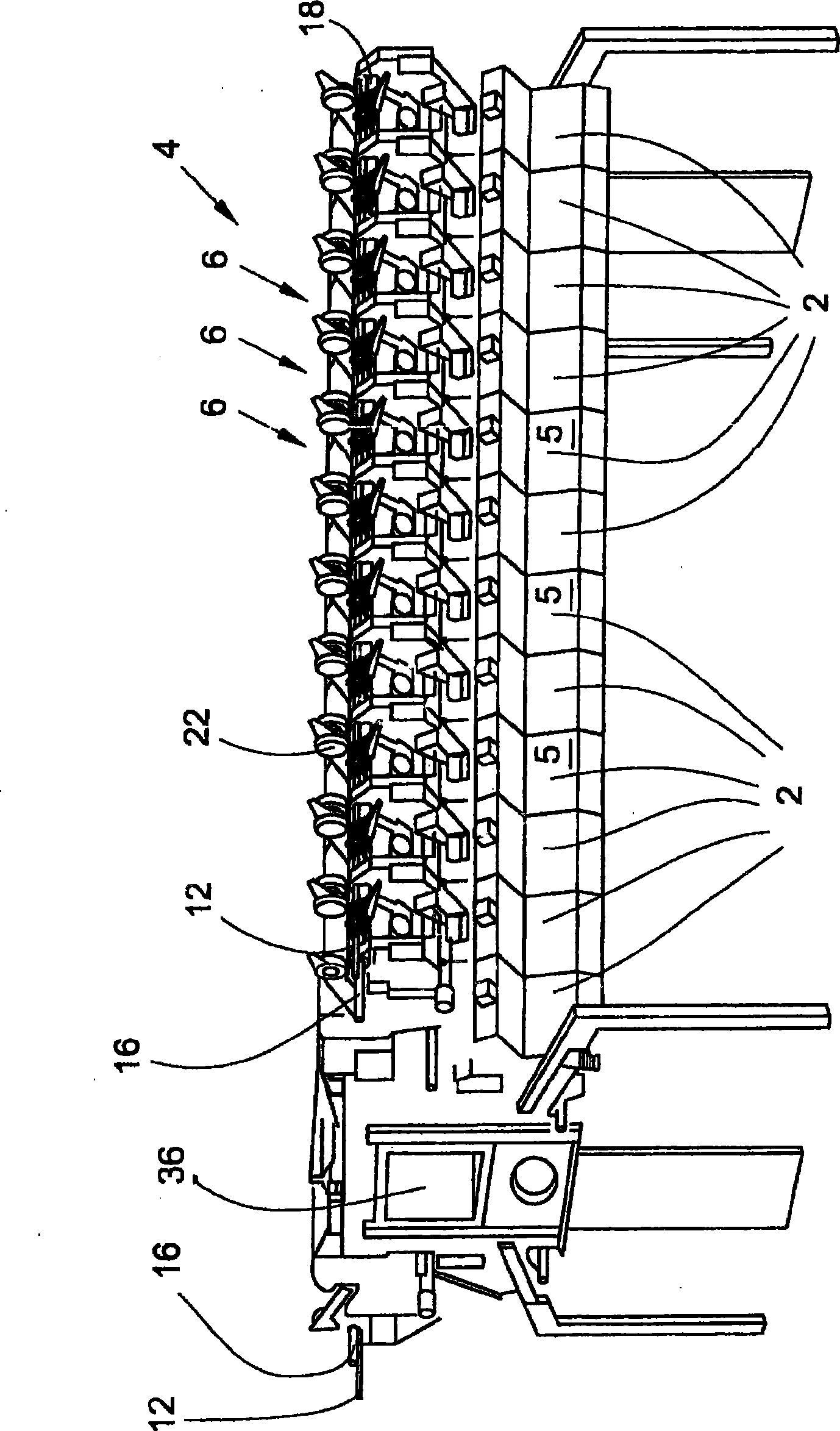

[0037] figure 1 An open-end rotor spinning machine 1 is shown as an embodiment of the spinning machine according to the invention, which has a plurality of work stations 2 and a frame 3 which is arranged approximately centrally between the work stations 2 . as in figure 1 described in and in figure 2 As further shown in , a plurality of these stations 2 are each combined into a part 4 which is generally a modular unit. The stations 2 themselves also each have an open-end spinning device 5 and a winding device 6 . As known, in the open-end spinning device 5, the fiber sliver fed in the spinning pot 7 is correspondingly spun into a yarn 8, which is then wound up on the winding device 6 as a cross-wrap Around the bobbin 9. The working mechanism of the workstation 2 is driven either by means of a so-called group drive or at least partially by means of an individual drive.

[0038] For example by means of such a group of drives actuated in Figure 4 with Figure 5 The yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com