Upper cover of pressure electric cooker

A rice cooker and pressure technology, which is applied to pressure cookers and other directions, can solve the problems of large heat generation, high suction power and high cost, and achieve the effects of safe use, low cost and low heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

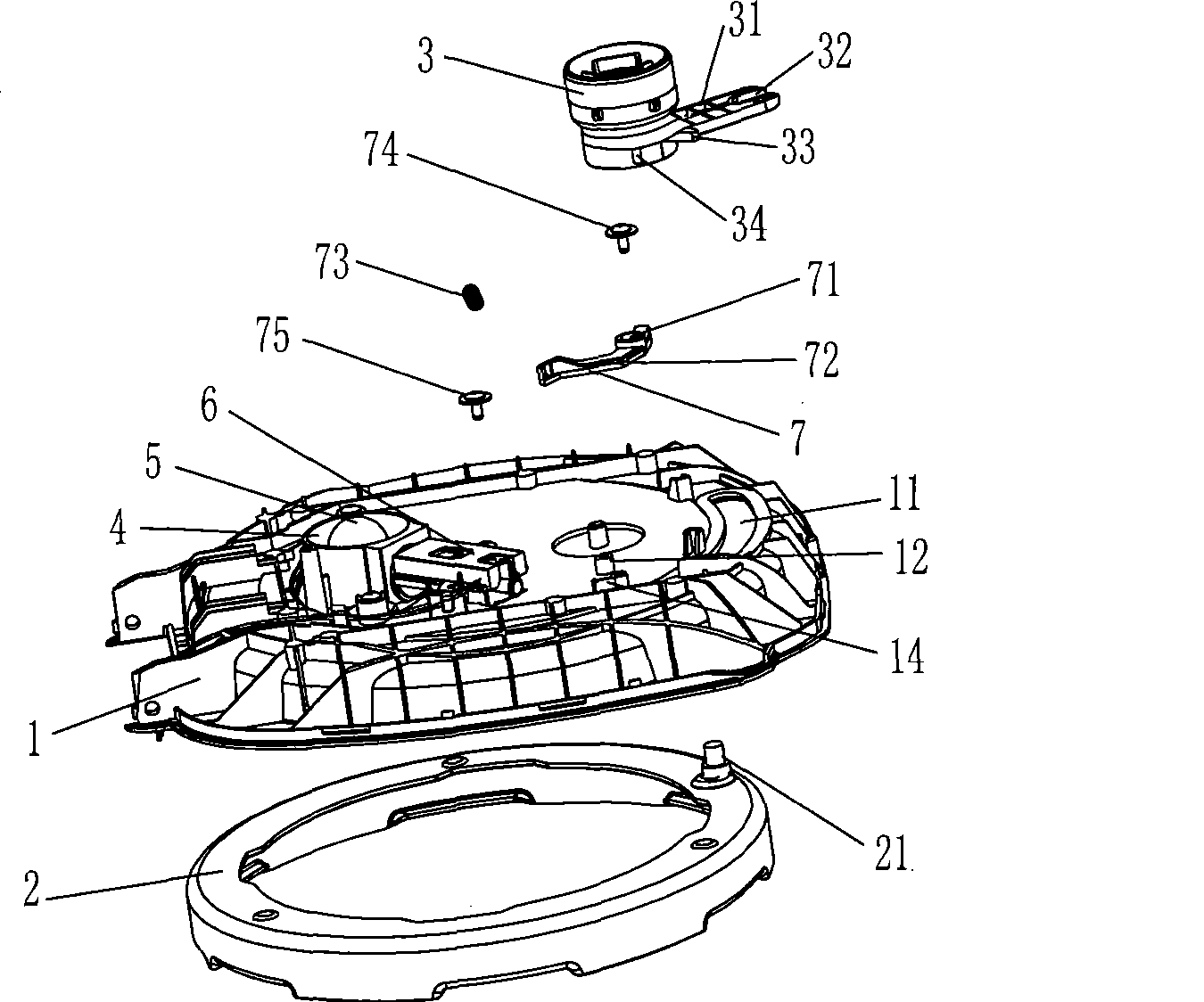

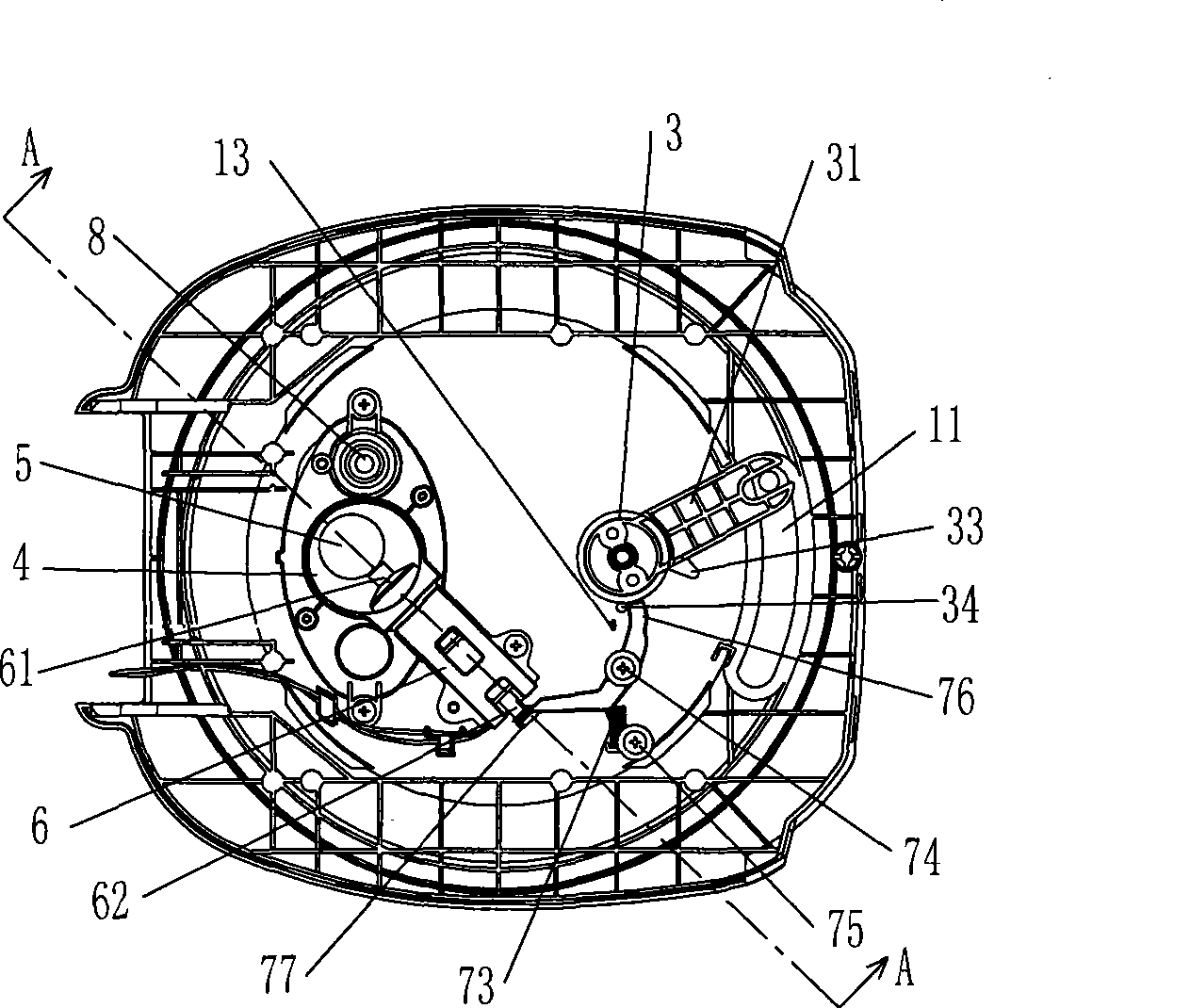

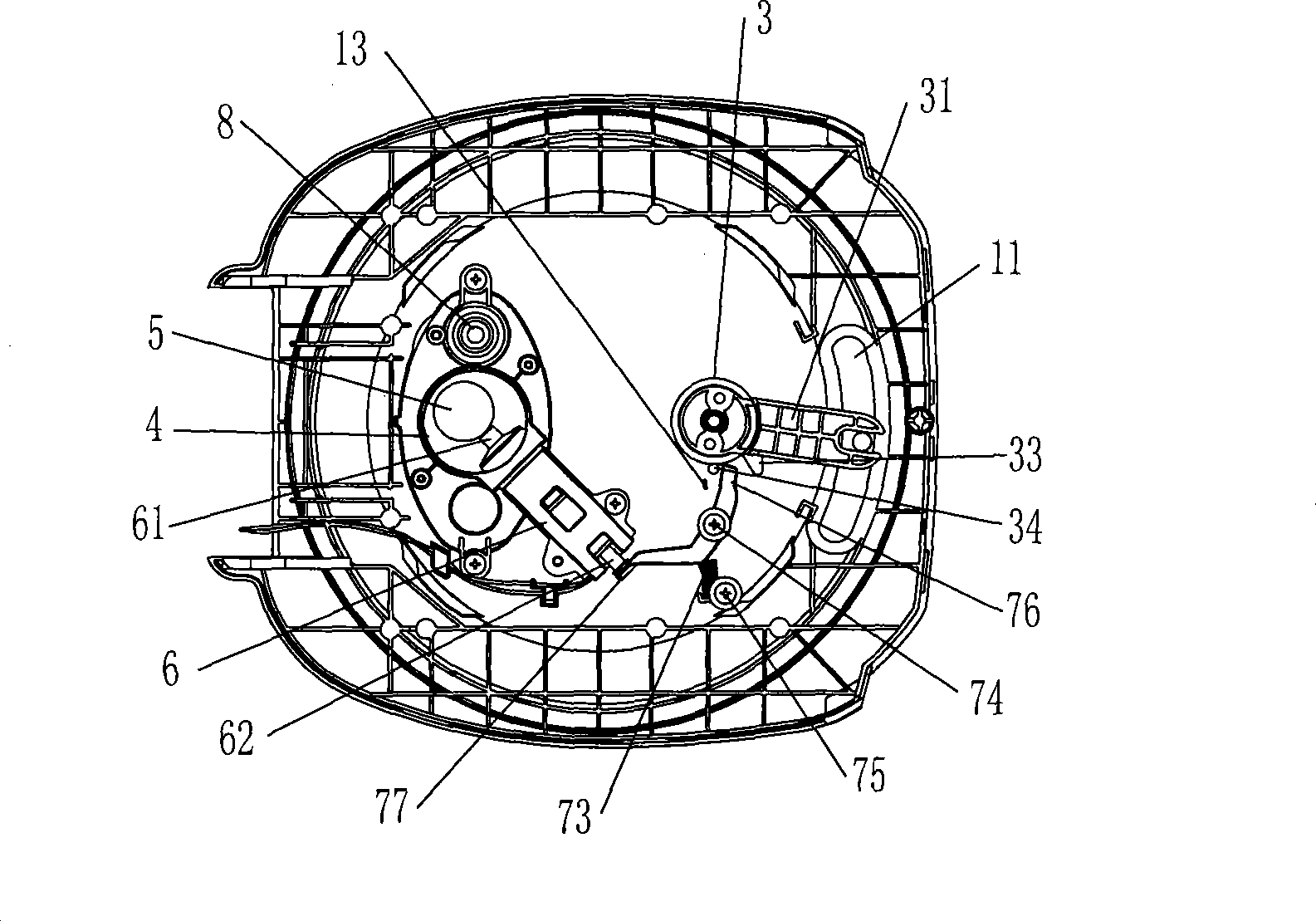

[0029] Such as figure 1 , figure 2 As shown, the upper cover of a pressure electric rice cooker in the present embodiment includes: an inner cover 1 hinged with the body of the pressure cooker (not shown in the figure), a lock catch 2 installed below the inner cover 1 and rotatable around its center, installed on The handle 3 on the top of the inner cover 1. The inner cover 1 is provided with an arc-shaped limit hole 11 along the circumference, and the corresponding limit hole 11 is provided with a limit pin 21 on the lock buckle 2. There is a pin hole 32 matched with the limit pin 21. When the user turns the rotary handle 3, the connecting rod 31 drives the limit pin 21 to slide along the limit hole 11, so that the lock catch 3 rotates, and the upper cover is locked. Transition between tight state and unlocked state.

[0030] Such as Figure 5 , 6 As shown, the inner cover 1 is provided with a pressure control mechanism composed of a steam channel 4 with a steam exhaust...

Embodiment 2

[0039] Such as Figure 7 , Figure 8 As shown, the difference between this embodiment and the first embodiment is that in the loam cake of the pressure rice cooker, the side of the handle 3 is provided with a drive arm 35 extending out horizontally, and the design of the drive arm 35 is long enough, and its end 351 can be connected with the electromagnet. The second end 62 of the push rod 6 directly interferes, and other features are the same as those in Embodiment 1, and will not be described in detail.

[0040] When the rotary handle 3 is turned until the limit pin 21 is located at the lowermost end of the limit hole 11, the upper cover is in an unlocked state, and the driving arm 35 rotates with the rotary handle 3, and the second end 62 of the electromagnet push rod 6 Thrust is generated, and the thrust overcomes the restoring force of the electromagnet itself to displace the push rod 6 and push the pressure ball 5 away from the exhaust hole 41, as Figure 5 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com