Solid base catalyst for preparing biodiesel

A solid base catalyst, biodiesel technology, applied in the direction of physical/chemical process catalyst, catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, etc., to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

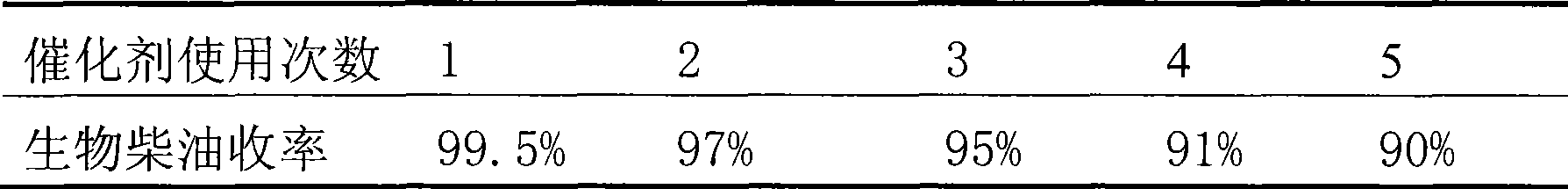

Examples

Embodiment 1

[0016] The preparation of solid base catalyst: with 0.36 moles (88.7 grams) MgSO 4 ·7H 2 O and 0.1125 mol (74.9 g) Al 2 (SO 4 ) 3 18H 2 O was dissolved in 315 ml of tap water to form a mixed salt solution, and 0.936 moles (37.4 grams) of NaOH and 0.45 moles (47.7 grams) of NaOH 2 CO 3 Dissolve in 315 ml of tap water to form a mixed alkali solution. Under full stirring, add the salt solution and alkali solution dropwise to 50 ml of tap water at the same time, at a rate of 15 ml / min. After the addition is complete, heat up to 80°C to crystallize Hours, a white precipitate was generated, which was separated by centrifugation, and the separated product was washed with tap water and dried at 90°C to obtain a hydrotalcite with a magnesium-aluminum ratio of 1.6:1: Mg 0.62 al 0.38 (OH) 2 (CO 3 ) 0.19 4H 2 O.

[0017] Preparation of biodiesel: 10g soybean oil and 30g methanol are added to the there-necked flask, and then 0.1g of magnesium aluminum hydrotalcite catalyst Mg ...

Embodiment 2

[0019] The preparation of solid base catalyst: with 0.36 moles (92.3 grams) Mg(NO 3 ) 2 ·6H 2 O and 0.12 mol (45.0 g) Al(NO 3 ) 3 9H 2 O was dissolved in 1000 ml of tap water to form a mixed salt solution, and 0.936 moles (52.4 grams) of KOH and 0.45 moles (62.1 grams) of KOH 2 CO 3 Dissolve in 235ml of tap water to make a mixed alkali solution. Under full stirring, add the alkali solution dropwise into the salt solution at a rate of 30ml / min. After the addition is complete, heat up to 60°C to crystallize for 6 hours, forming a white precipitate , filtered with a funnel, and the separated product was washed with tap water and dried at 80°C to obtain a hydrotalcite with a magnesium-aluminum ratio of 3:1:Mg 0.75 al 0.25 (OH) 2 (CO 3 ) 0.125 ·5H 2 O.

[0020] Preparation of biodiesel: 10g rapeseed oil and 80g ethanol are added to the there-necked flask, and then 0.2g of magnesium aluminum hydrotalcite catalyst Mg 0.75 al 0.25 (OH) 2 (CO3 ) 0.125 ·5H 2 O, the reac...

Embodiment 3

[0022] The preparation of solid base catalyst: with 0.36 moles (34.2 grams) MgCl 2 and 0.036 moles (4.8 grams) of AlCl 3 Dissolved in 315 ml of tap water to form a mixed salt solution, 0.18 moles (17.3 g) (NH 4 ) 2 CO 3 Dissolve in 100ml of tap water and 215ml of 25% ammonia water to form a mixed alkaline solution. Pour the salt solution into the alkaline solution under full stirring, and then heat up at 40°C to crystallize for 10 hours to form a white precipitate. Draw it out with a funnel filtered, the separated product was washed with tap water, and dried at 100°C to obtain a hydrotalcite with a magnesium-aluminum ratio of 10:1::Mg 0.91 al 0.09 (OH) 2 (CO 3 ) 0.045 ·6H 2 O.

[0023] Preparation of biodiesel: 10g rapeseed oil and 150g propanol are added to the there-necked flask, and then 0.4g of magnesium aluminum hydrotalcite catalyst Mg 0.91 al 0.09 (OH) 2 (CO 3 ) 0.045 ·6H 2 O, the reaction was stirred at 97°C for 2 hours. After the reaction is finished, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap