Anti-jam trough of garbage transfer station

A technology of transfer station and clogging, which is applied in the direction of garbage transmission, garbage collection, transportation and packaging, etc., can solve the problems of light specific gravity, unsafe manual operation, inconvenient mechanized operation, etc., and achieve the goal of eliminating clogging and solving bloated phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

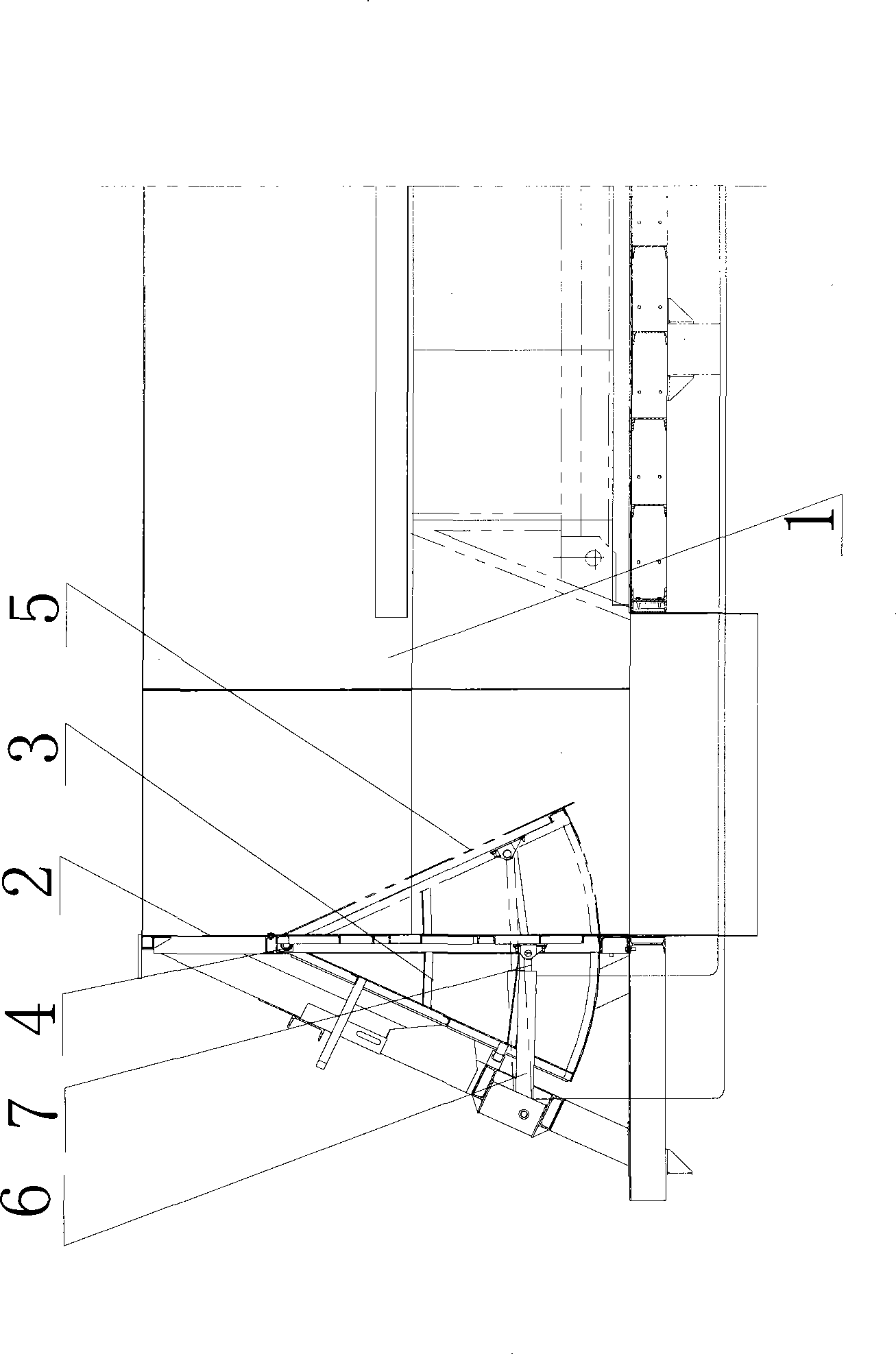

[0014] figure 1 It is a schematic diagram of the structure of the anti-canopy blocking material trough of the garbage transfer station of the present invention, including a trough body 1, and a window structure that opens into the trough body and a transmission device connected thereto are installed on the side plate 2 of the trough body 1. Under the action of the transmission device, the window structure opens into the tank to eliminate the material clogging in the tank. The window structure includes a window 3 and a rotating pin 4, and the window 3 can rotate around the rotating pin 4. The transmission device includes a hydraulic cylinder 6 and a piston rod 7, and the piston rod 7 is connected with the window 3.

[0015] Rotation bearing pin 4 links to each other with the upper end of form 3, and form rotates and is to move upwards, and the material that the form lower end pierces fluffy blocking upwards, and material descends. The lower end of the form 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com