Fabrication technique of antiskid polyurea terrace paint surface

A floor coating and manufacturing technology, applied to polyurea/polyurethane coatings, coatings, floors, etc., to achieve fast construction speed, comfortable feet, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

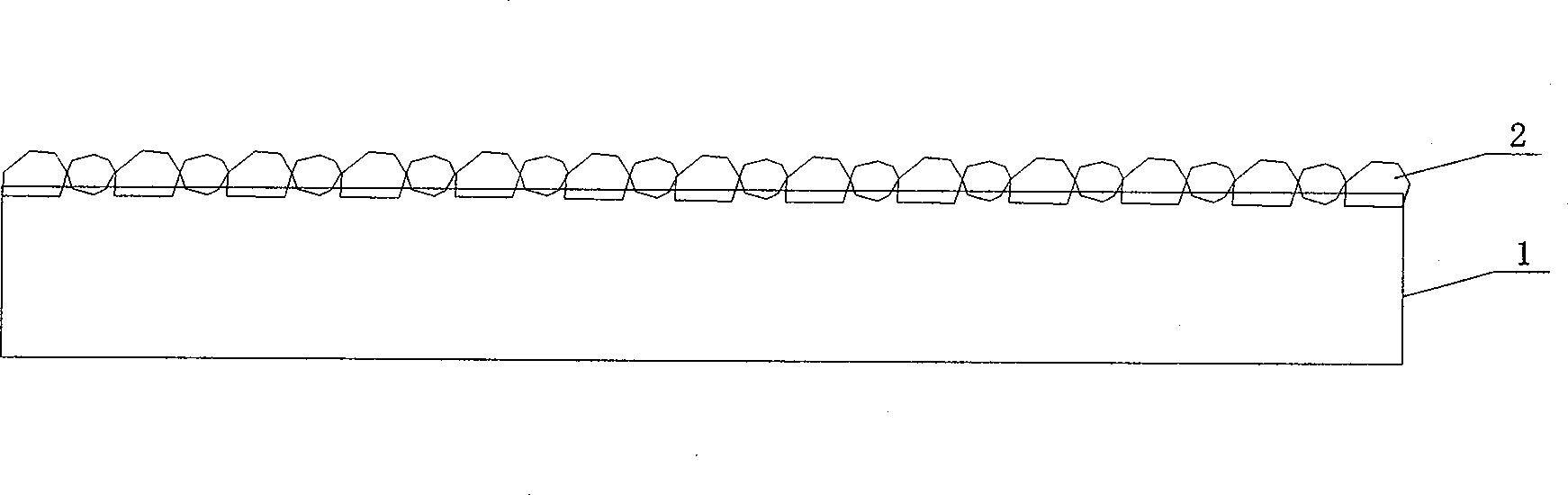

[0026] figure 1 The schematic diagram of the anti-skid type polyurea floor coating surface layer structure of this embodiment is shown, and the main steps of the manufacture technology of this anti-skid type polyurea floor coating surface layer are as follows: earlier use the spray gun GX-7 of spraying polyurea to the surface as the substrate Spread and spray polyurea on the cement floor to form a homogeneous polyurea elastomer base layer 1 with a thickness of about 2 mm; after spraying polyurea for 7 seconds, spray quartz sand on the homogeneous polyurea elastomer base layer 1 with a spray gun FR- 300 Spray quartz sand with a particle size of about 0.8-1.2mm to form the anti-slip layer 2 of quartz sand particles. The homogeneous polyurea elastomer base layer 1 and the quartz sand particle anti-slip layer 2 constitute the anti-slip polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com