Detection method for osmotic concentration of vehicle fuel tank welding point and connector

A detection method and technology of penetration concentration, which is applied in the field of detection of penetration concentration of welding points and joints of automobile fuel tanks, and can solve the problems of inability to measure the local concentration of welding points and joints, large penetration of welding points or joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

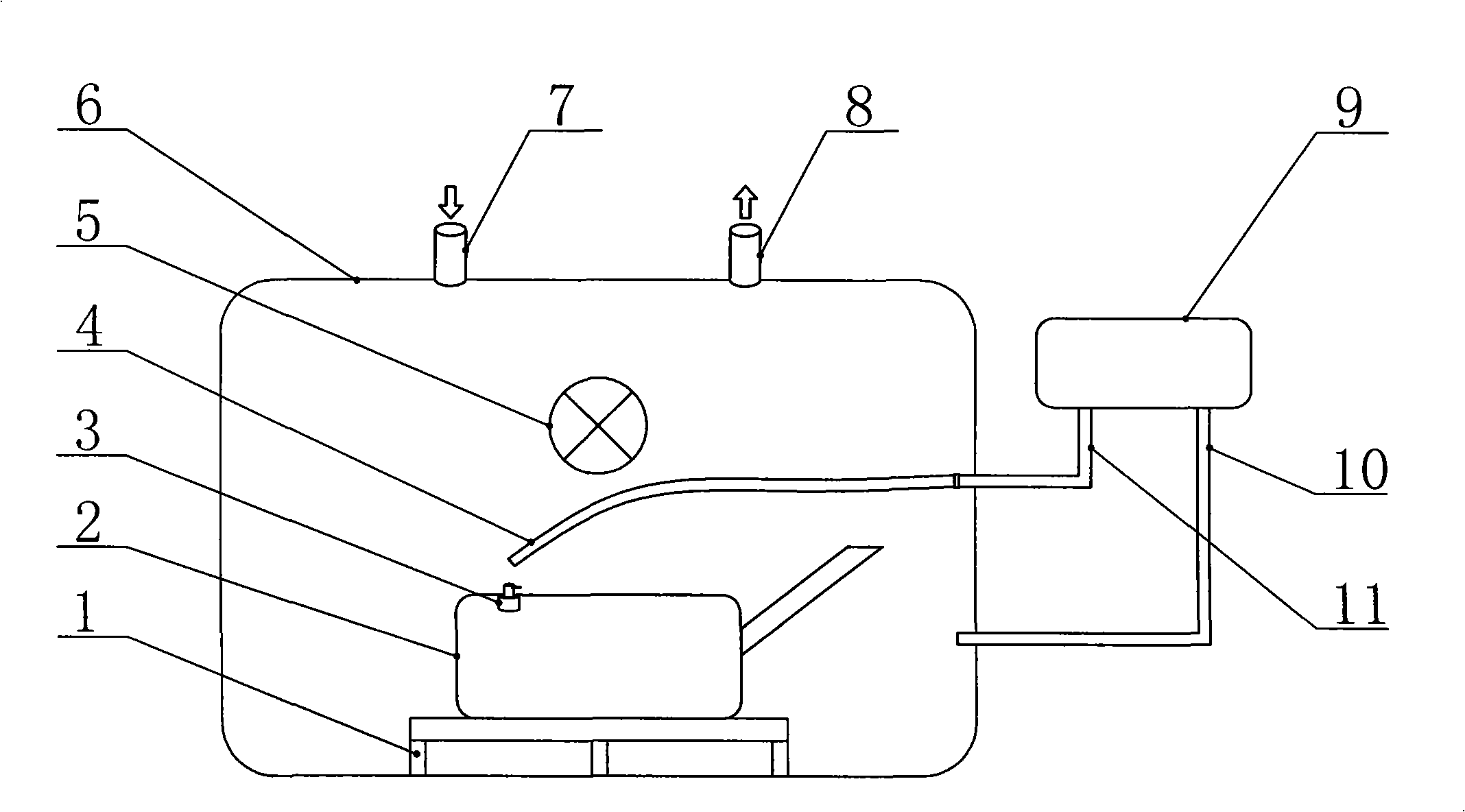

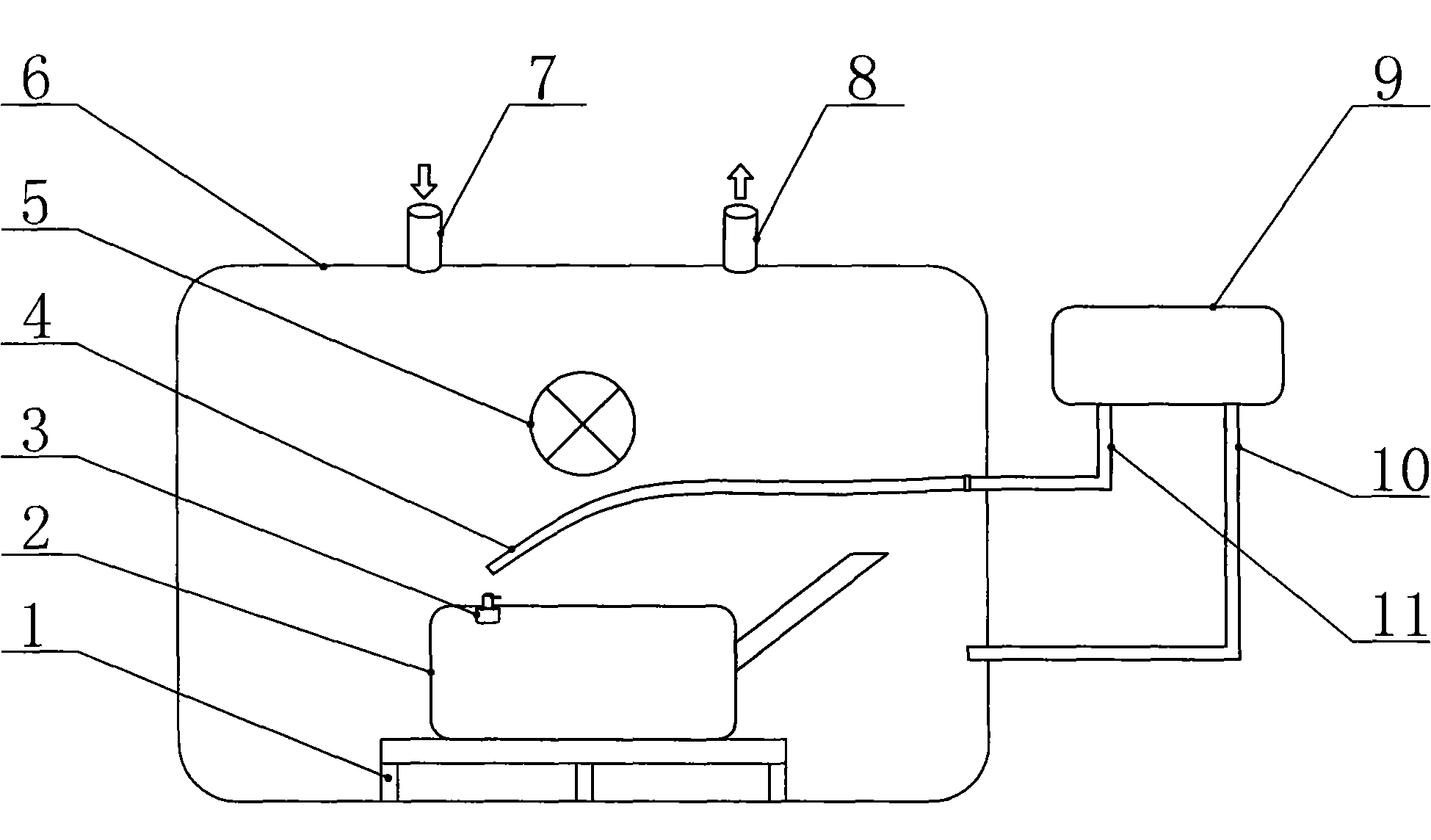

[0009] Such as figure 1 As shown, the detection method of the automobile fuel tank welding point and joint penetration concentration of the present invention comprises the following steps: first the automobile fuel tank 2 is placed on the support 1 in the test box 6, and the test box 6 is integrally heated to make the test box When the air temperature in 6 reaches 36°C, turn on the internal circulation fan 5 in the test box 6 to keep the temperature field in the test box 6 uniform, adjust the heating intensity, and keep the air temperature in the test box 6 at 36°C for 1 hour; Then open the outer circulation air inlet 7 and the outer circulation air outlet 8 on the test box wall, make the fuel vapor hydrogen helium concentration in the test box stabilize at 3ppm by the outer circulation ventilation system; then start the flame power detector 9, test box 6 The air in the flame enters the flame power detector 9 from the sampling port 11, and then returns to the test box 6 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com