Seat excitation apparatus used for MEMS dynamic characteristics test

A technology of dynamic characteristics and bottom plate, which is applied in the direction of measuring device, vibration test, machine/structural component test, etc. It can solve the problems of high natural frequency, small structure size of MEMS micro devices, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

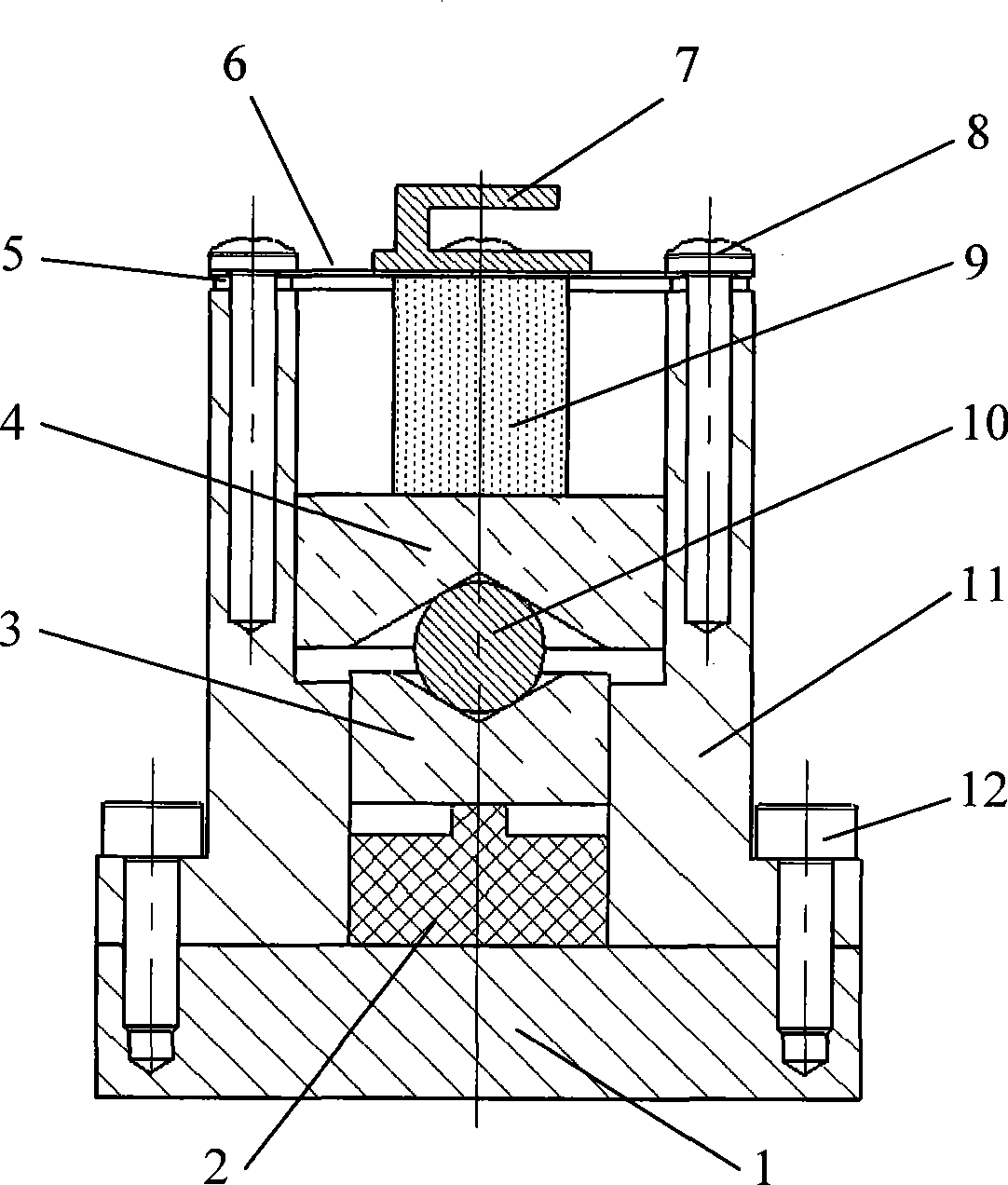

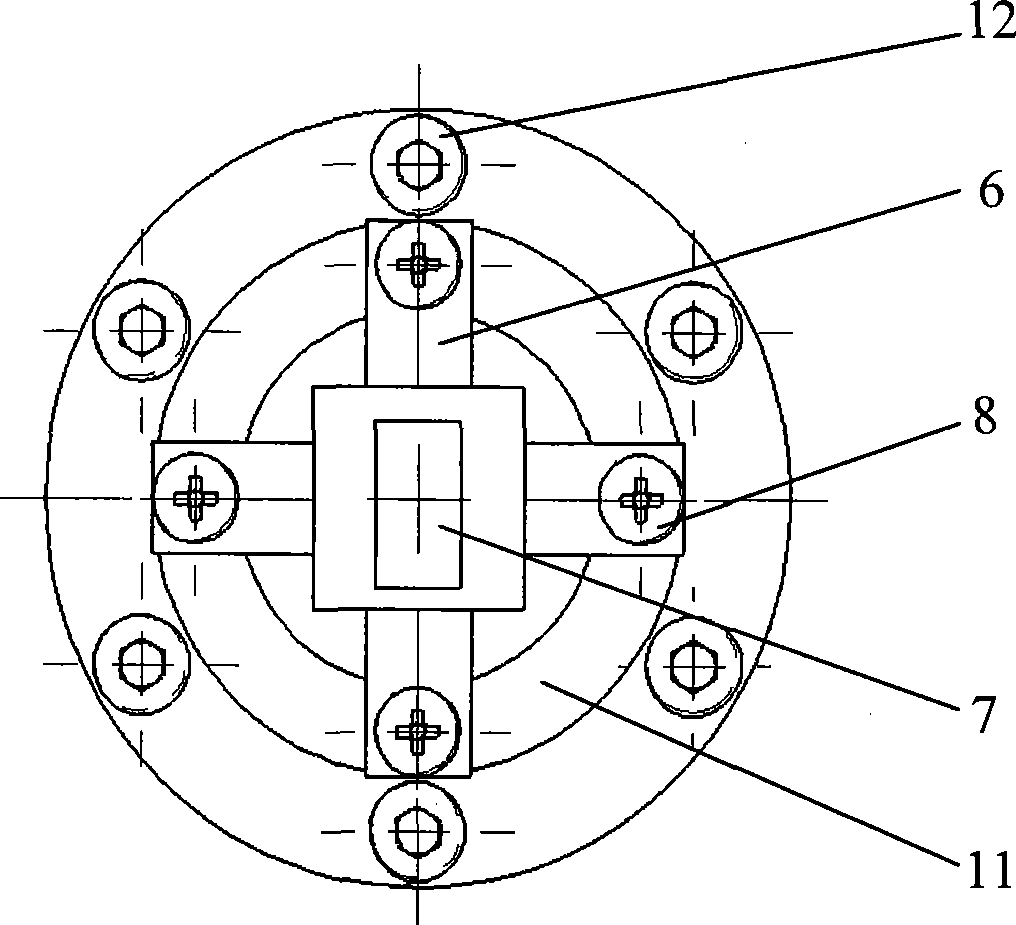

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0016] like figure 1 and figure 2 As shown, the micro-device 7 to be tested is directly bonded to the cross spring 6 on the top with glue, the adhesive should ensure as rigid a connection as possible between the micro-device 7 and the cross spring 6, and the cross spring 6 passes through the screw 8 Installed on the top of sleeve 11.

[0017] The pressure sensor 2, the lower connecting block 3, the steel ball 10, the upper connecting block 4, and the piezoelectric ceramic 9 are installed inside the sleeve, the bottom of the piezoelectric ceramic 9 is glued to the upper connecting block 4, and the top and the cross spring piece 6 Contact; by changing the thickness of the adjusting gasket 5, the cross spring piece 6 is deformed to exert an axial pretightening force on the piezoelectric ceramic 9;

[0018] The upper connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com