Position S type instruction generation method

A technology of instruction and implementation method, applied in the field of position S-type instruction generation, to achieve the effects of avoiding shock and vibration, stable operation, and flexible parameter setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

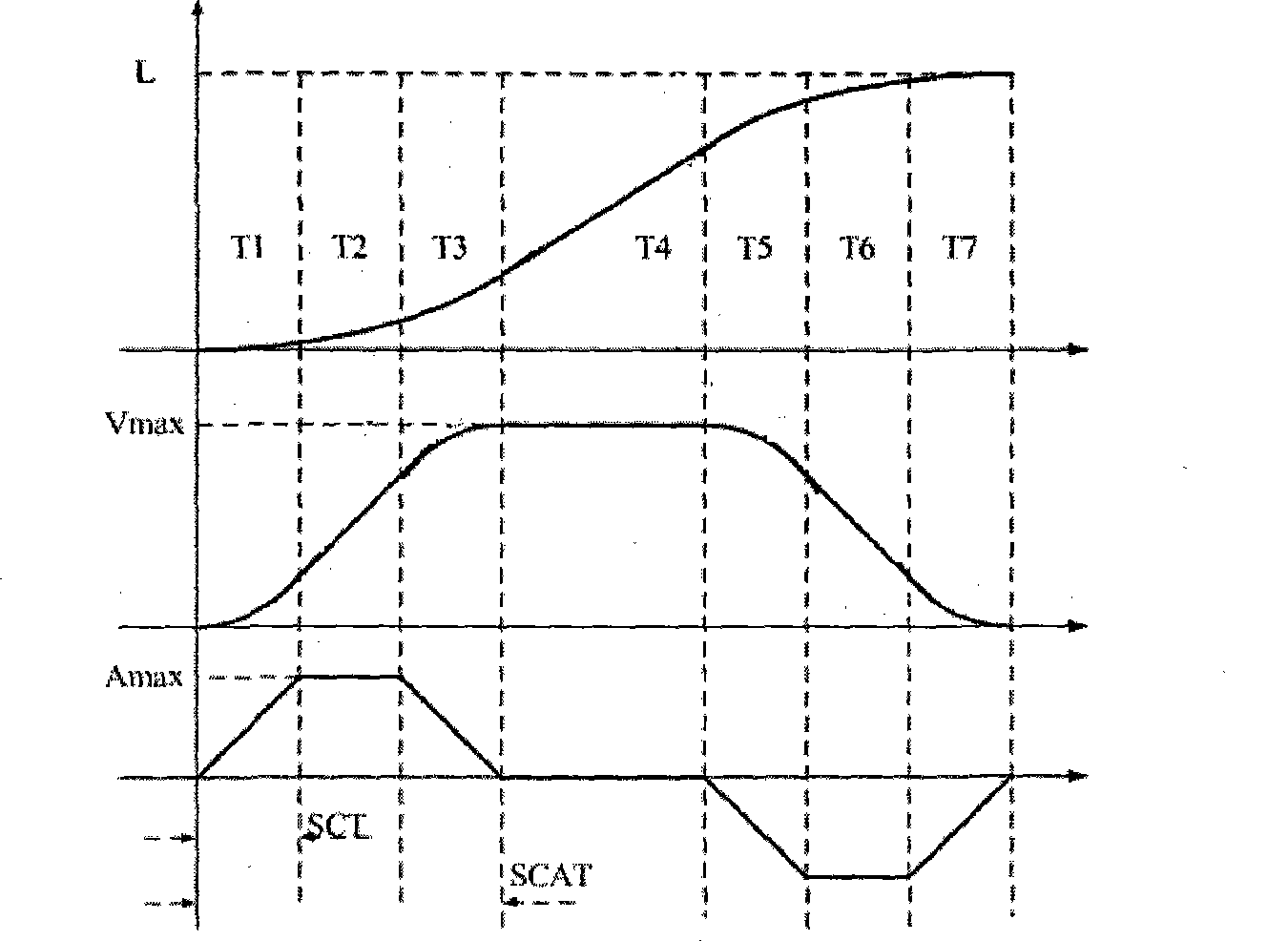

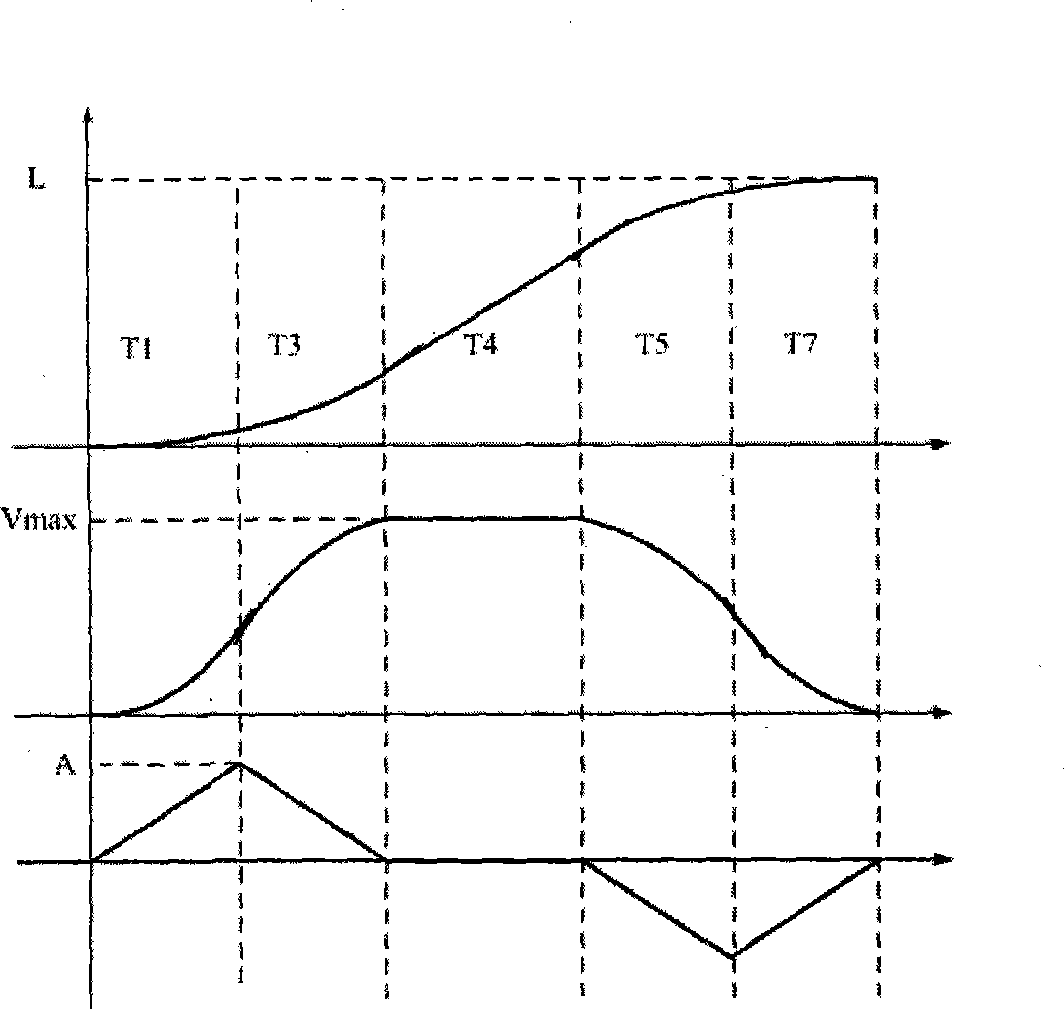

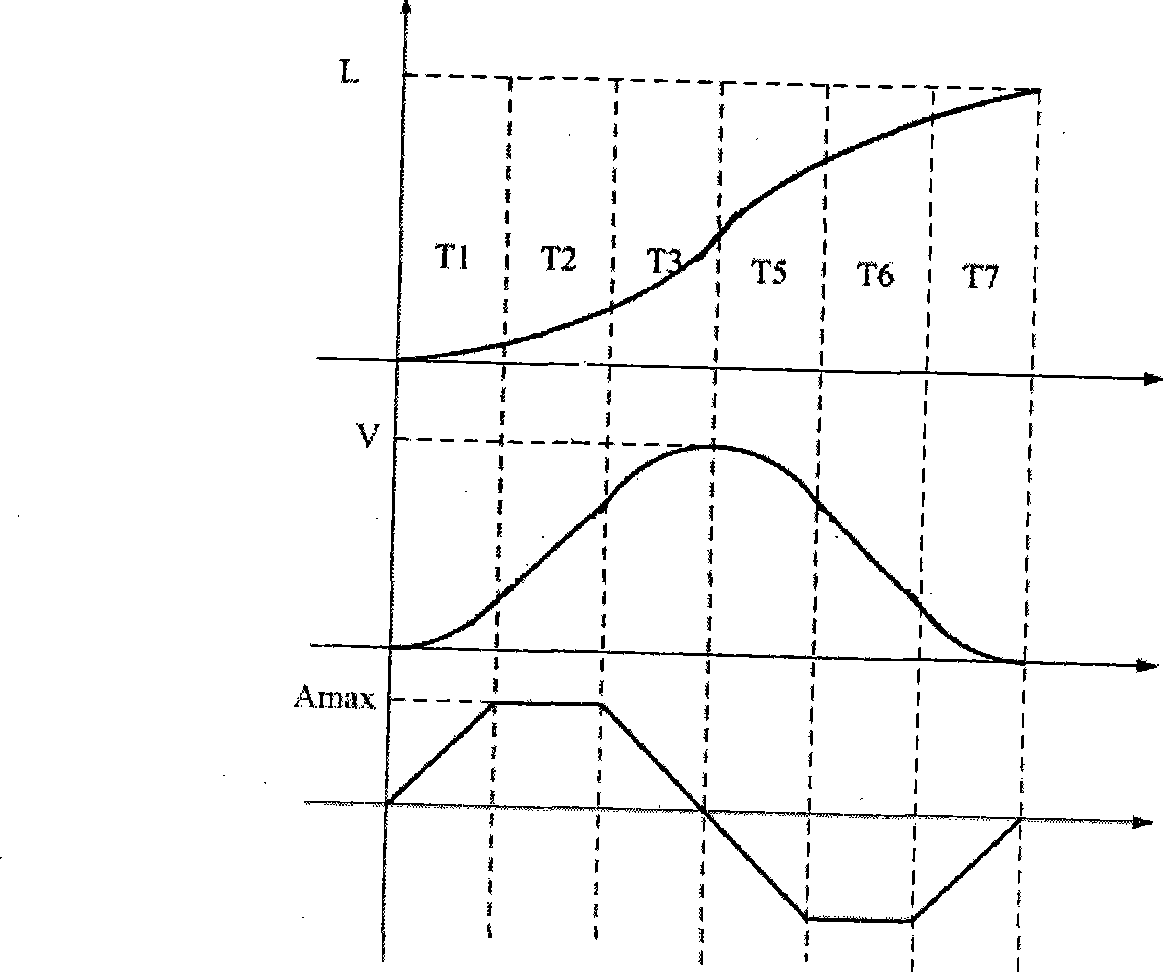

[0031] Such as figure 1 As shown, a typical S-curve includes three processes of S-curve acceleration, constant speed and deceleration. Among them, the acceleration process includes the jerk section (T1), the uniform acceleration section (T2) and the deceleration section (T3). Deceleration and deceleration section (T7), the whole process is divided into seven sections. In the figure, SCT is the smoothing time constant, SCAT is the acceleration time constant, Vmax is the set maximum operating speed, L is the displacement command value, and Amax is the maximum acceleration allowed by the system.

[0032] From time 0, the acceleration of the system increases linearly from zero. At the end of T1, the acceleration reaches a constant value, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com