Aircraft side fairing

A technology for fairing panels and aircraft, applied in aircraft parts, fuselage, mechanical equipment, etc., can solve the problems of unfavorable insulation of sidewall panels, reduced aircraft performance, etc., and achieve the effects of reducing aircraft weight, improving heat insulation effect, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the drawings, unless otherwise stated, identical reference numerals designate identical or functionally identical components.

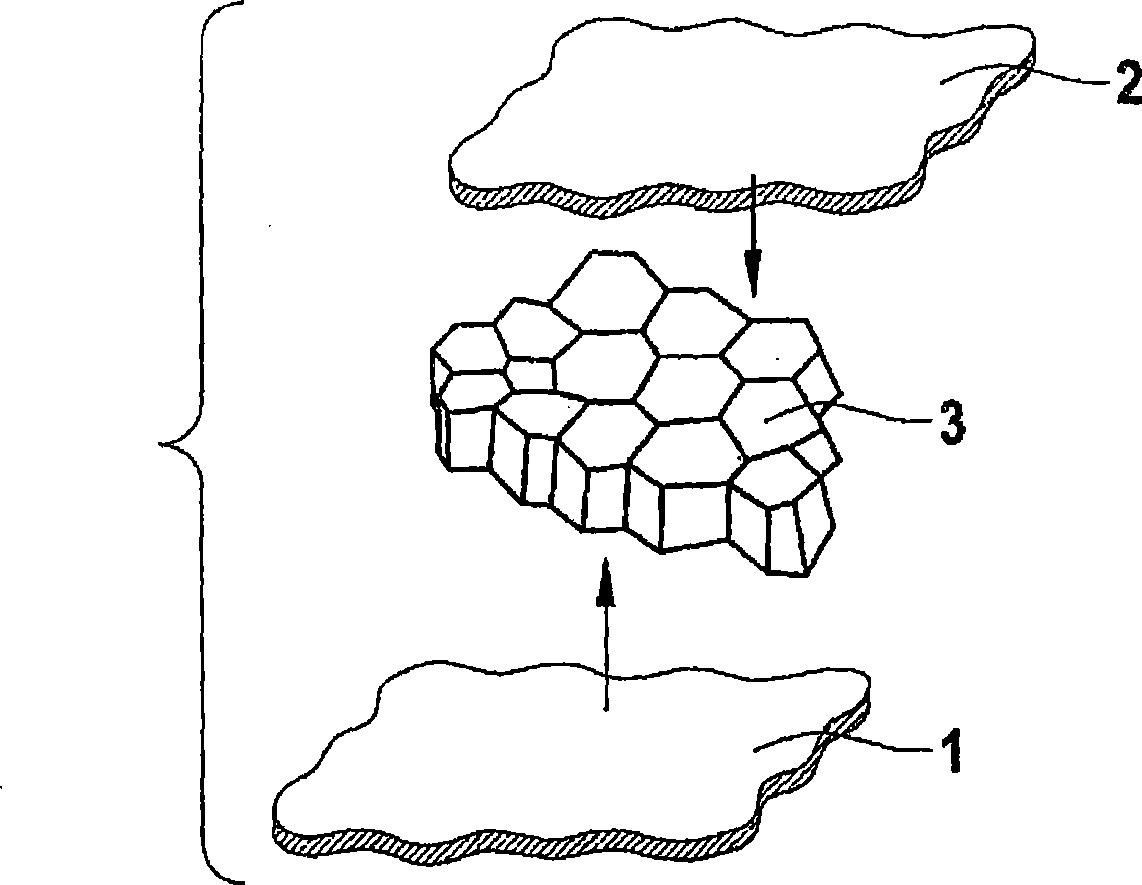

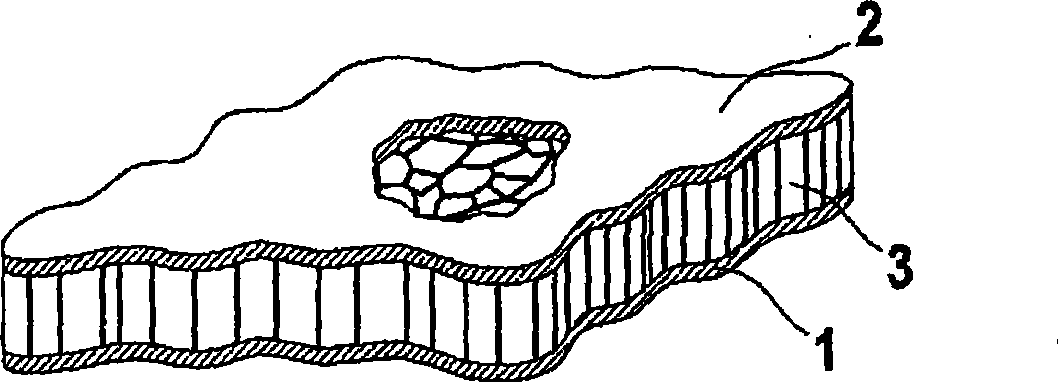

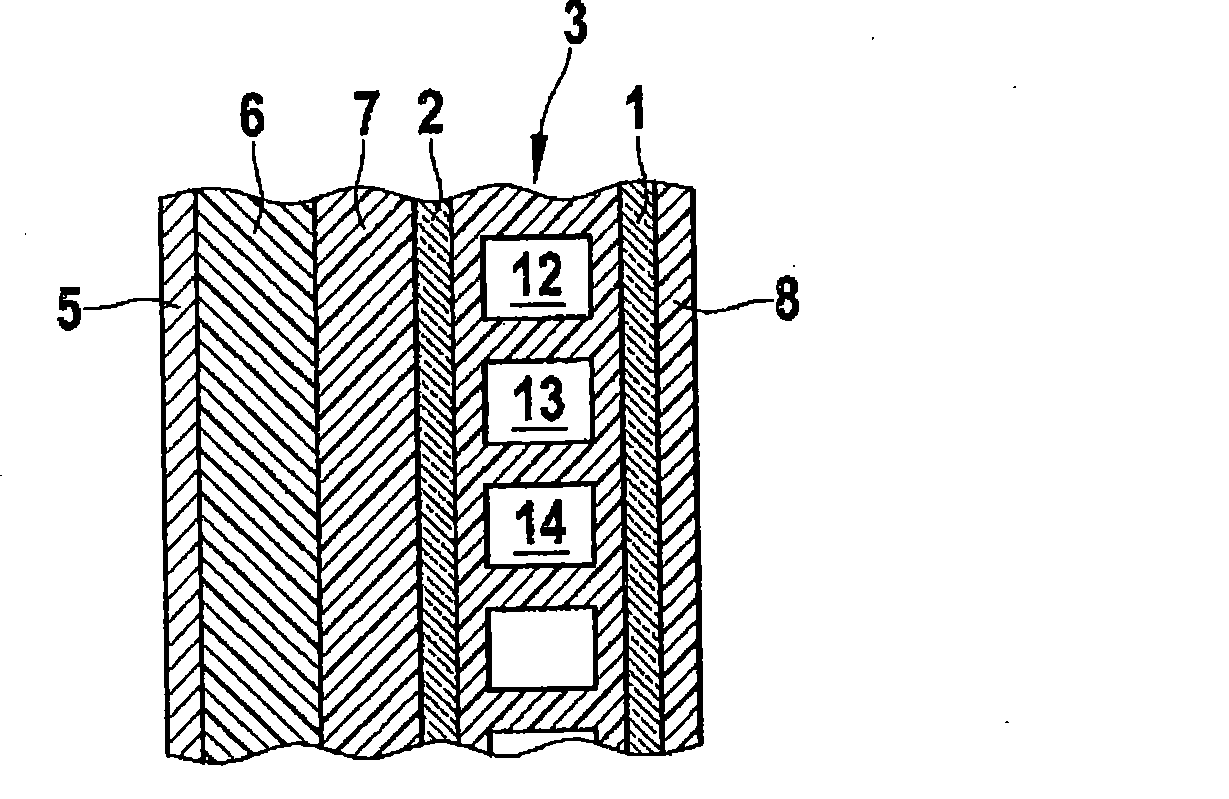

[0037] Figures 1 to 3 A cross-sectional view of a side fairing according to the prior art is shown for reference. according to figure 1 , provided with a core material for an aircraft side fairing comprising a first covering layer 1 and a second covering layer 2 with a core material 3 in the form of a hollow cavity between the layers lying on a plane, if appropriate a curved plane, And has a honeycomb structure. The honeycomb structure 3 composed of hollow cavities and the hollow cavities are made of non-metallic material impregnated with resin, while the covering layers 1, 2 glued to the hollow cavities are made of glass fibers impregnated with synthetic resin. figure 2 shows the basis of figure 1 The structure composed of the parts 1, 2, 3 after sticking together can be clearly seen that the covering layers 1, 2 are roughly parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com