Reciprocating type gear shift pedal structure for scooter

A reciprocating, scooter technology, applied in the field of bicycles, can solve problems such as insufficient input power, difficulty in maintaining stability, and inability to go uphill, so as to improve the ability to adapt to road conditions, overcome insufficient output power, and difficulty in pedaling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

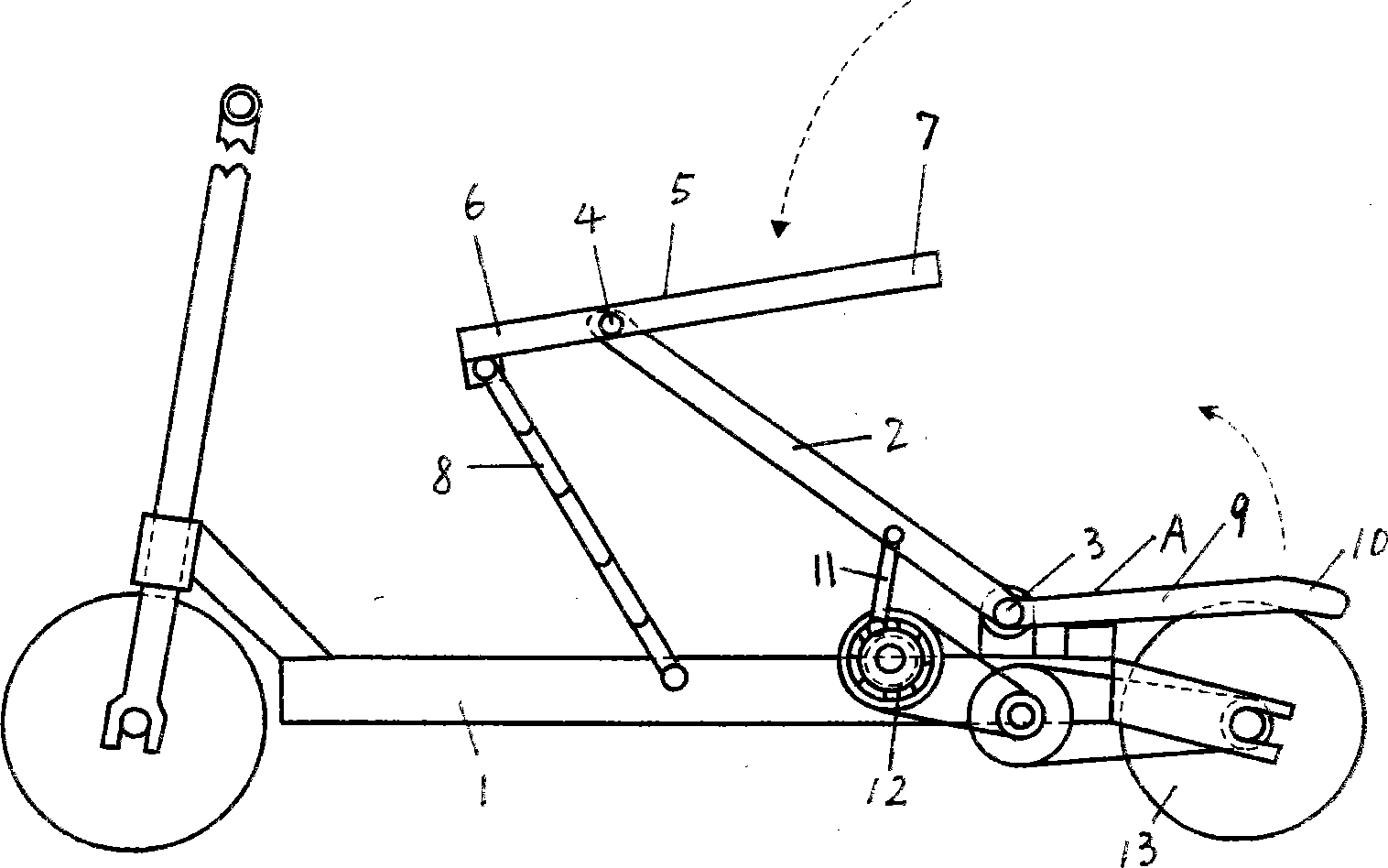

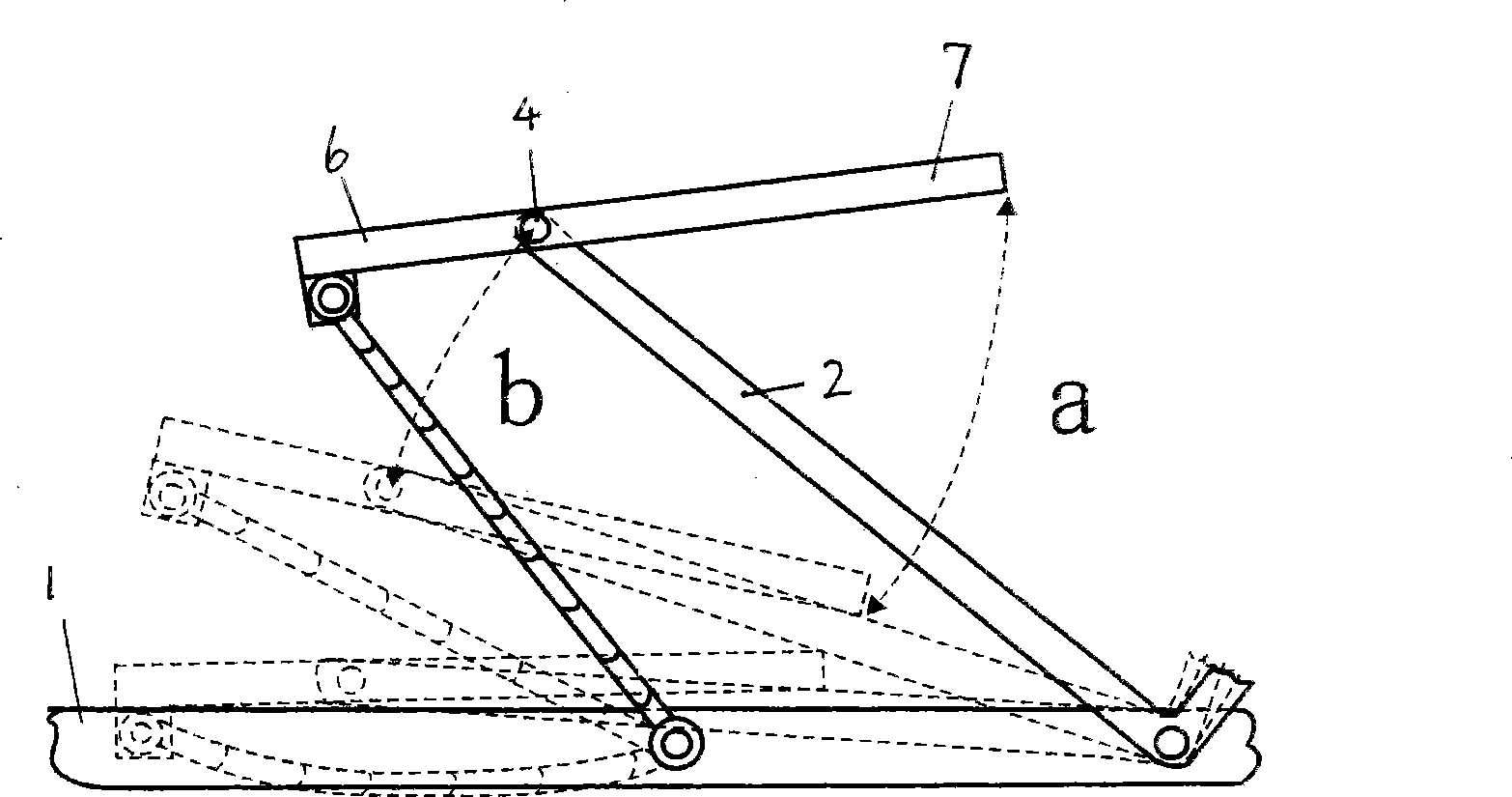

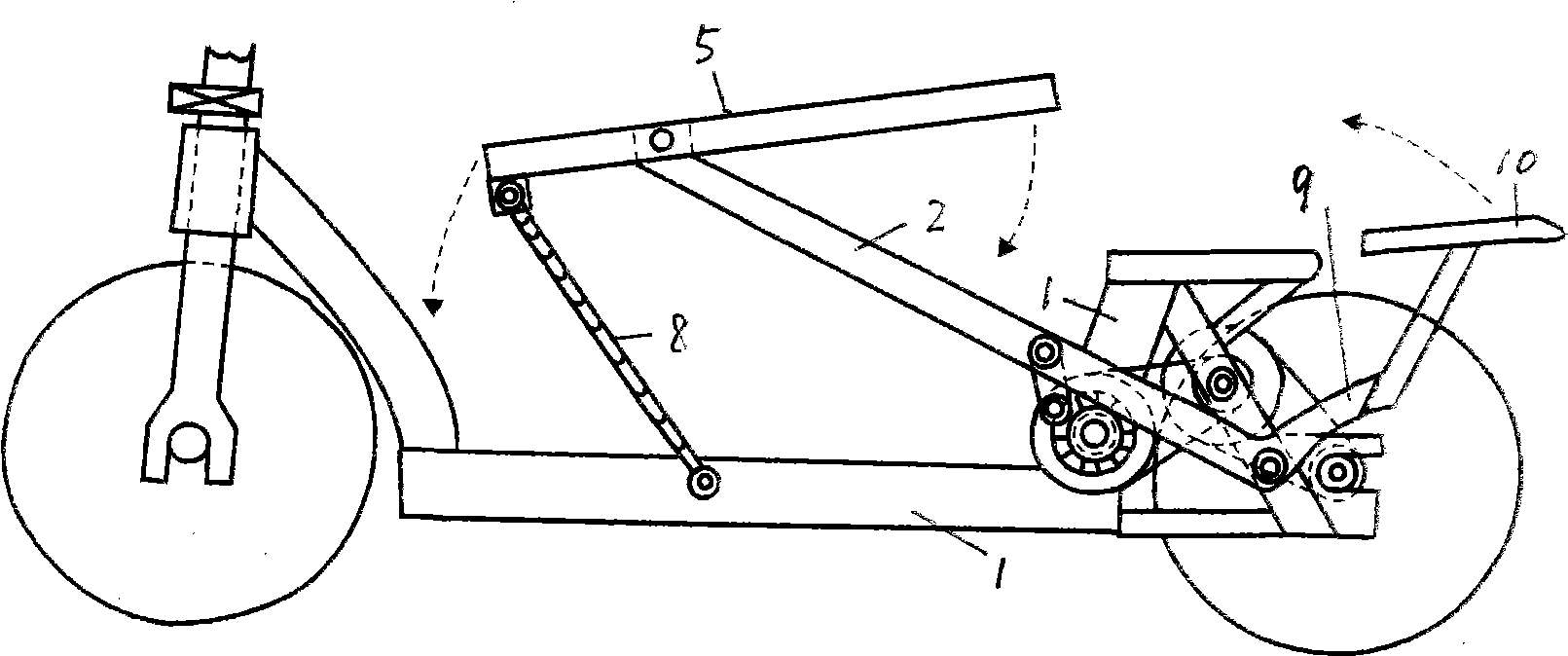

[0034] Embodiment 1: The single-power reciprocating speed change pedal structure of the flexible plate return type.

[0035] The structure of the reciprocating speed change pedal in this embodiment is a single-power reciprocating speed change pedal structure of the flexible plate return type, see figure 1 , it has a power pressure rod 2 that can be movably connected to the scooter frame 1, the power pressure rod 2 is actually movably connected to the vehicle frame 1 through the shaft 3, and the upper end of the power pressure rod 2 is movably connected with a movable pedal through the shaft 4 5 and the movable pedal is divided into two parts, the limit end 6 and the labor-saving end 7, and the movable connecting member 8 which can limit the movable pedal range of motion is arranged between the front part of the movable pedal limiting end and the vehicle bracket, and the movable connecting member Pull rope or zipper structure is adopted; the return mechanism A of the power pres...

Embodiment 2

[0039] Embodiment 2: Flexible board return type dual power reciprocating speed change pedal structure.

[0040] The structure of the reciprocating speed change pedal in this embodiment is a flexible plate return type double power reciprocating speed change pedal structure, see Figure 16-19 . Figure 16 Among them, the power pressure rod 2 is two sets of front and rear, which are connected as a whole to directly form a flexible plate structure. In the linkage of one up and one down, they form the return mechanism of the other side. The power output has two sets of independent ratchet systems. , also known as an off-axis double ratchet structure; Figure 17 and Figure 16 The structure is roughly the same, but the power output adopts a coaxial double ratchet structure. Figure 18 Among them, the power pressure rods 2 are also two sets of front and rear, and are coaxially movably connected on the vehicle bracket, and a connection return spring 19 is arranged between the two, ...

Embodiment 3

[0042] Embodiment 3: Elastic return type single power reciprocating speed change pedal structure.

[0043] The reciprocating speed change pedal structure of this embodiment is an elastic return type single power reciprocating speed change pedal structure, see Figure 21 . Figure 21 Among them, the return mechanism A of the power pressure rod 2 adopts a tension spring 21 structure, and can also be used Figure 22 shown in the structure of the torsion spring 22, of course Figure 21-22 Compression spring structure can also be used, Figure 23 bungee cord construction as shown or Figure 25-26 Shown shoe hook, shoe cover structure. In fact, the return mechanisms of all the solutions described in Embodiment 1 can be realized by using extension springs, compression springs, torsion springs, elastic cords, shoe hooks or shoe covers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com