Operation method for organic solid waste aerobic compost deodorizing nitrogen keeping apparatus

A technology of aerobic composting and organic solids, which is applied in the field of solid waste disposal and recycling, and achieves the effects of simple operation, low operating cost and favorable absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0020] Specific embodiment one (the present invention):

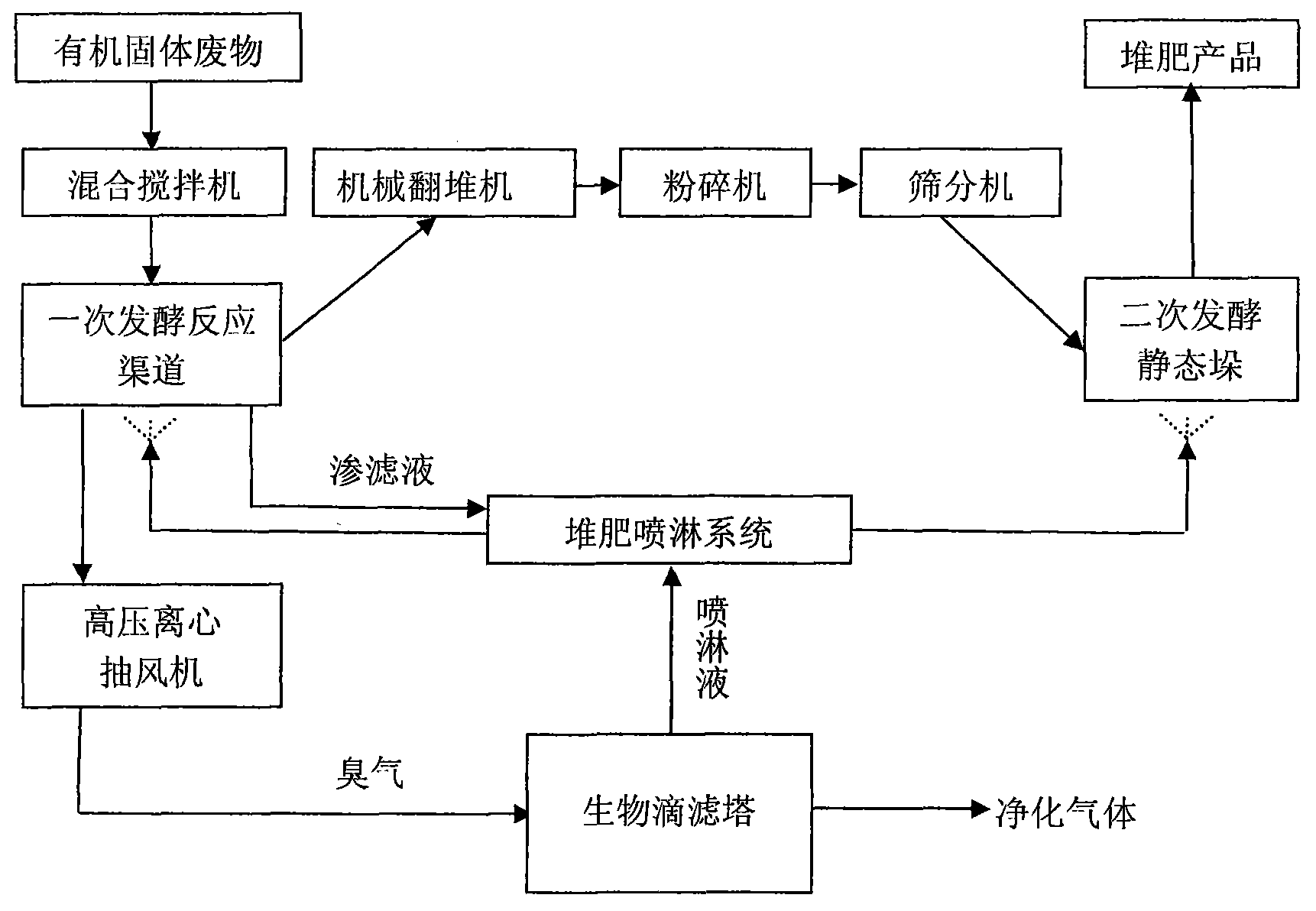

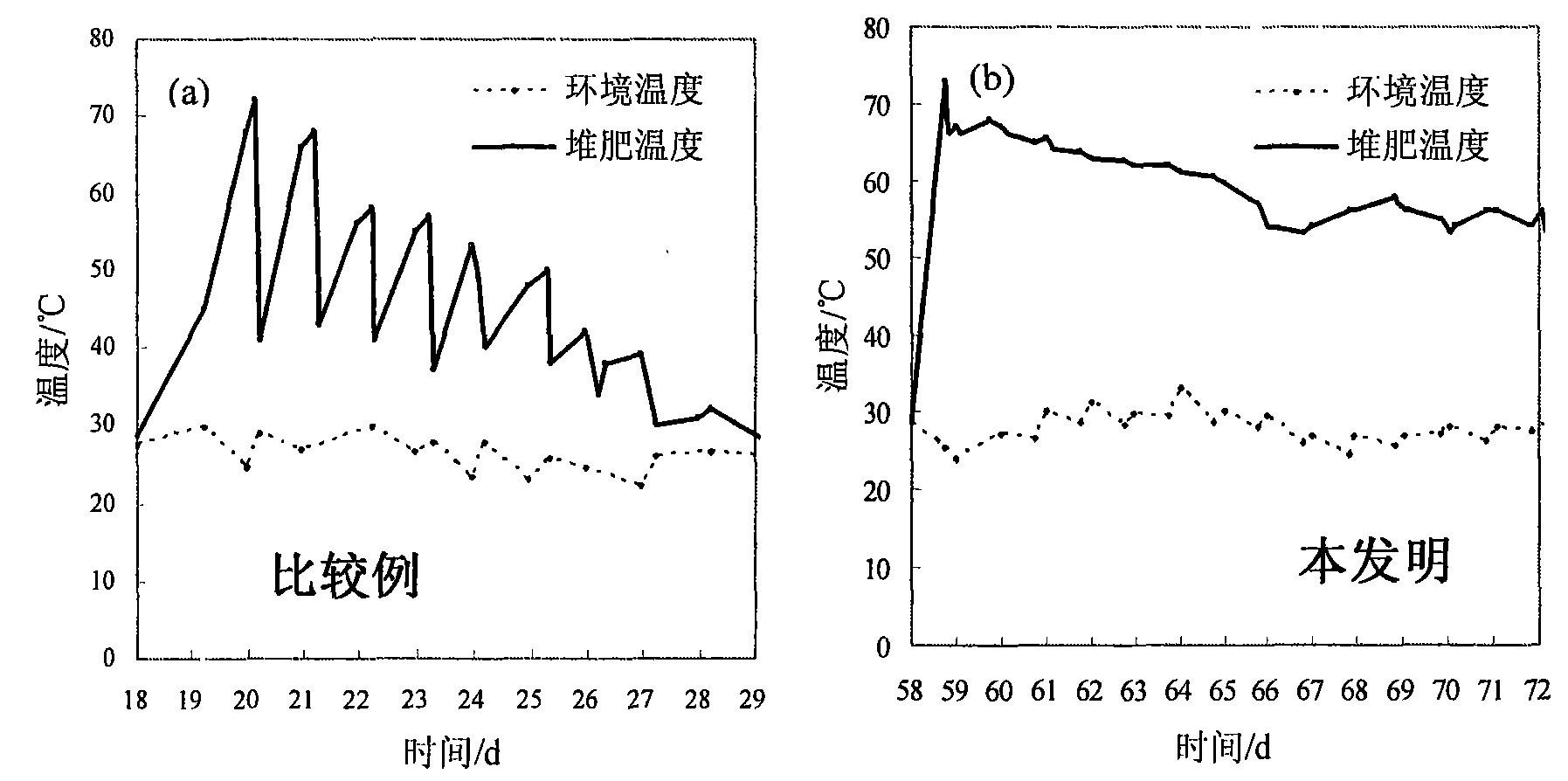

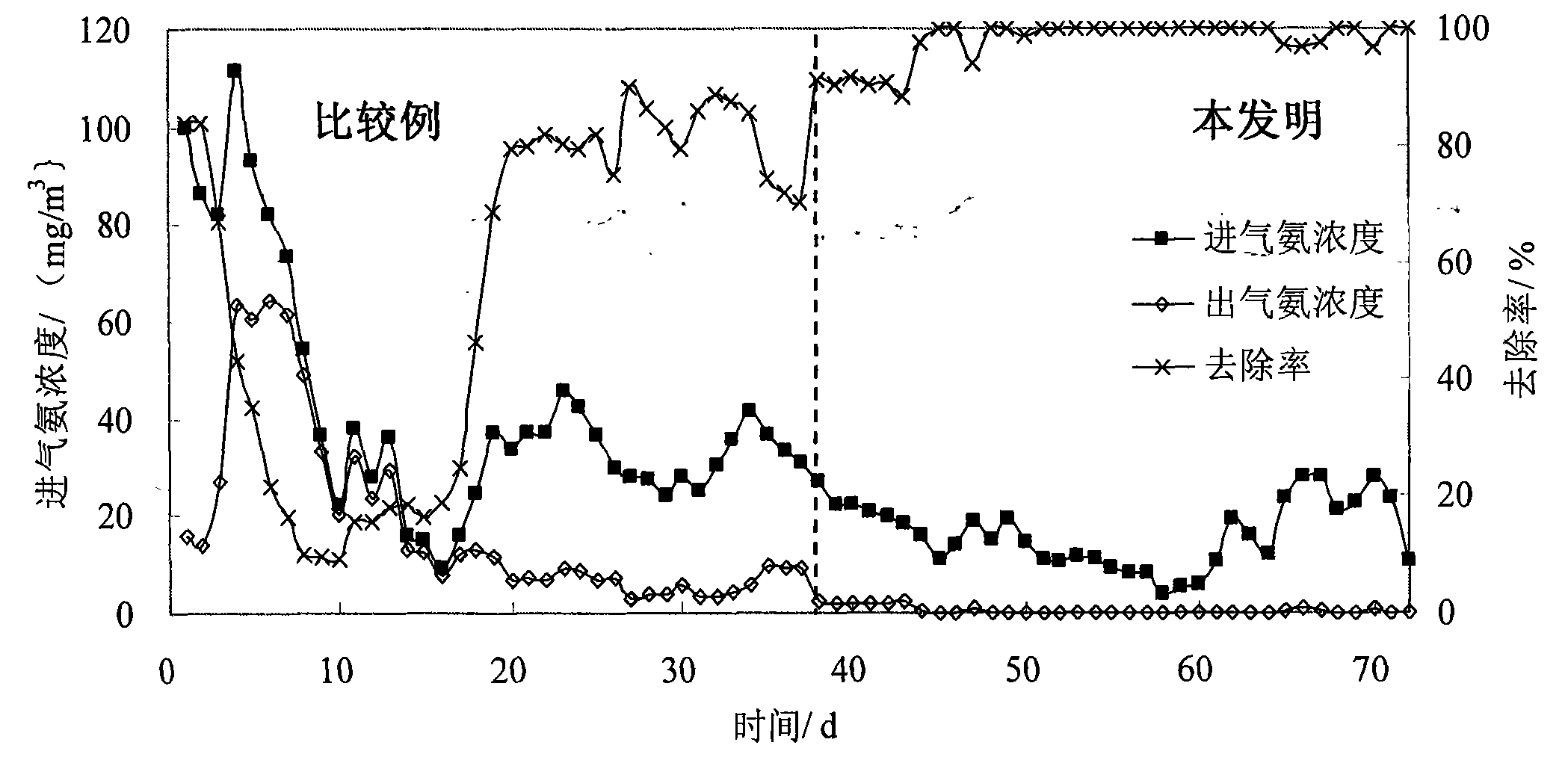

[0021] Such as figure 1 As shown, in this example, cow dung and mushroom dregs are used as composting raw materials, and by adding nitrogen-containing materials and other auxiliary materials, the organic matter content of the initial composting mixed raw materials is adjusted to 50%-60%, C / N=25-30:1, water content The rate is 45% to 50%. The above-mentioned compost raw materials and auxiliary materials are mixed by a mixing mixer and then poured into a fermentation reaction channel. After aerobic fermentation, they are forced forward by a mechanical compost turner to reach the pulverizer; Screening machine, the products under the screen are stacked into static stacks for secondary fermentation, and the stacked materials are bagged after the secondary fermentation is completed. The bottom of the primary fermentation reaction channel is provided with an air extraction branch pipe, which is connected to the main air extr...

specific Embodiment 2

[0024] Specific embodiment two (comparative example):

[0025] Specific embodiment two differs from specific embodiment one in that: (1) a low-pressure high-volume centrifugal fan is connected in series in the pipeline between the outlet of the high-pressure centrifugal exhaust fan and the inlet at the bottom of the biological trickling filter tower, and the gas flow is changed from the original 900m 3 / h becomes 3500m 3 / h The corresponding gas residence time in the bio-trickling filter tower is changed from 36s to 9.2s; (2) The method of controlling the stockpiling temperature is different. Lower the temperature until the central temperature of the pile is lower than 45°C and stop running. Such as figure 2 Shown; (3) The waste liquid respray system is not activated. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com