Full membrane water cooling type intermediate frequency induction heating capacitor

An induction heating, capacitor technology, applied in high voltage, high current resonant capacitor. ,In the field of intermediate frequency, it can solve the problems of reducing the volume of capacitors, increasing the overcurrent capacity, and high frequency of use, and achieve the effects of reducing eddy currents, increasing service life, and reducing heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

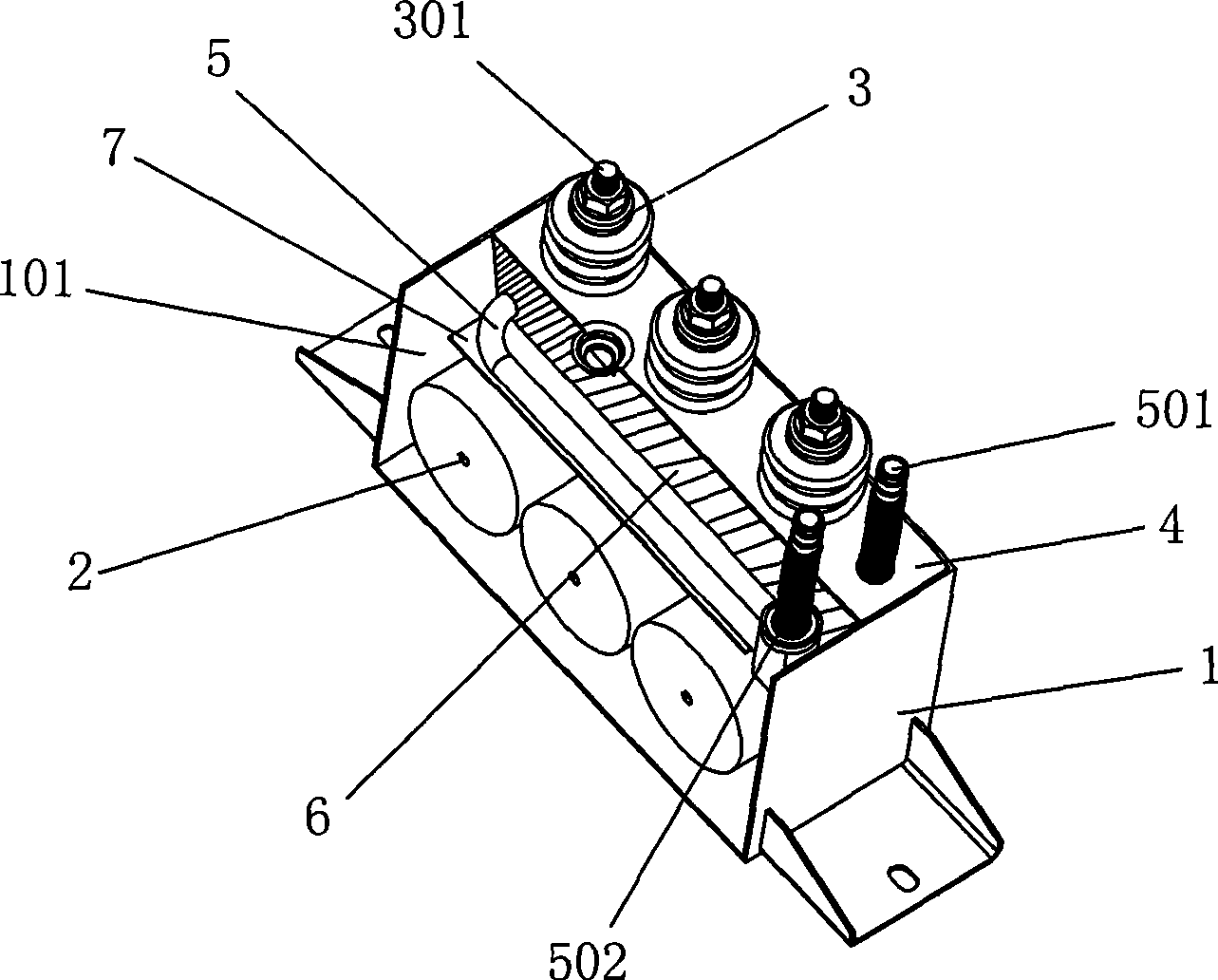

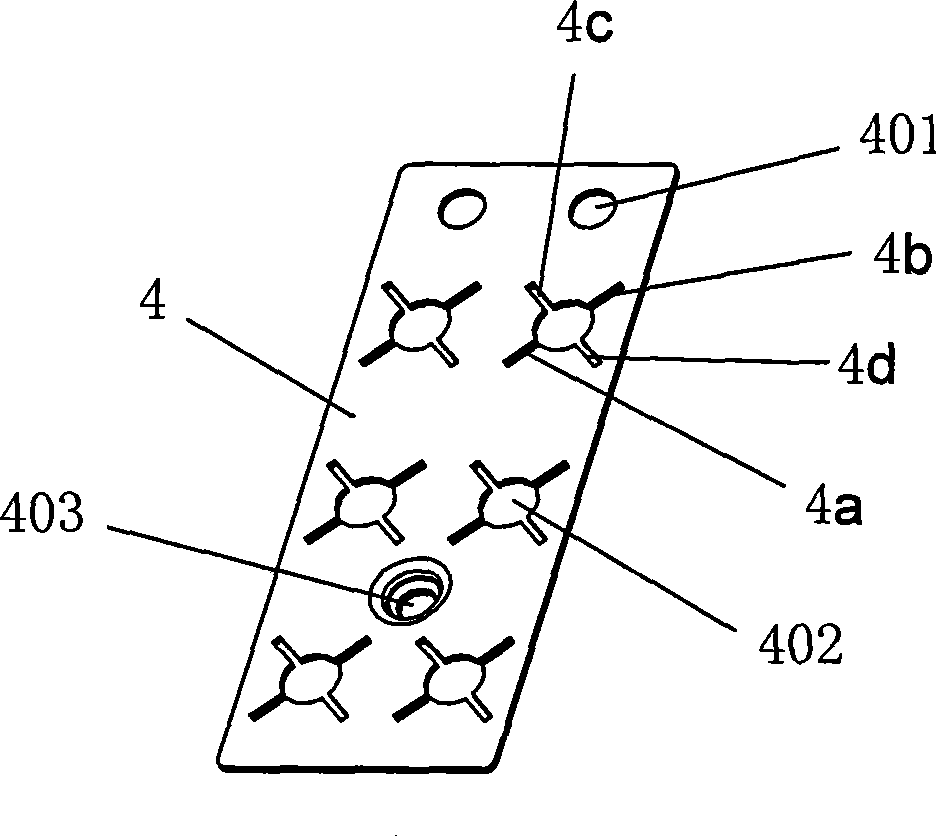

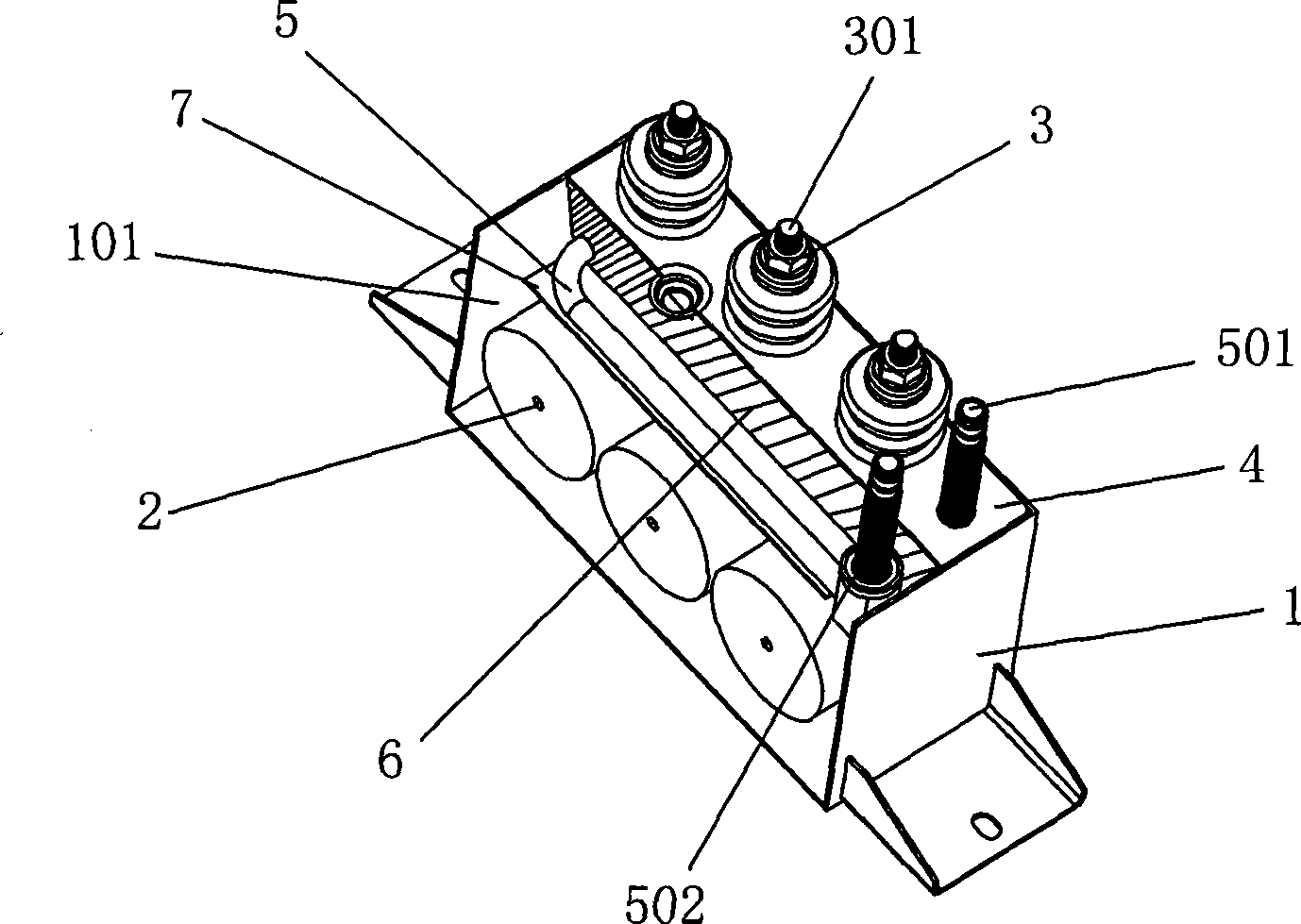

[0036] Such as Figure 1 to Figure 11 As shown, a full-film water-cooled intermediate frequency induction heating capacitor includes a shell 1 and a capacitor core 2. A housing cavity 101 is opened on the shell 1, and a capacitor core 2 is installed in the housing cavity 101. The capacitor core 2 is provided with a leak-proof core lead-out end 3, the upper opening of the accommodating cavity 101 of the housing 1 is fixed with an isolation upper cover 4, and a U-shaped lead-out end is provided in the accommodating cavity 101 near the core lead-out end 3. The end cooling channel 5, the two ends 501, 502 of the lead-out cooling channel 5 and the outer end 301 of the core lead-out 3 respectively extend out of the isolation upper cover 4, and the two ends of the U-shaped lead-out cooling channel 5 also serve as common lead-out electrodes, The accommodating cavity 101 is also filled with heat-resistant and flame-retardant semi-dry organic matter as a heat sink 6, and the capacitor c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap