Method for injecting fuel by means of fuel injection system

Technology of a fuel injection system and fuel injection valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below with the aid of Figure 1-7 The invention is described by way of example.

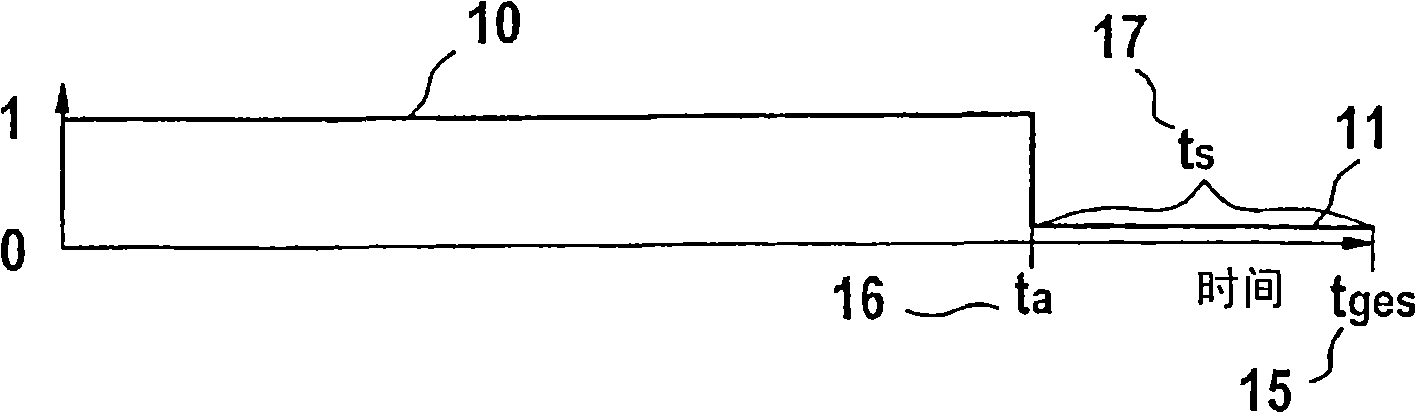

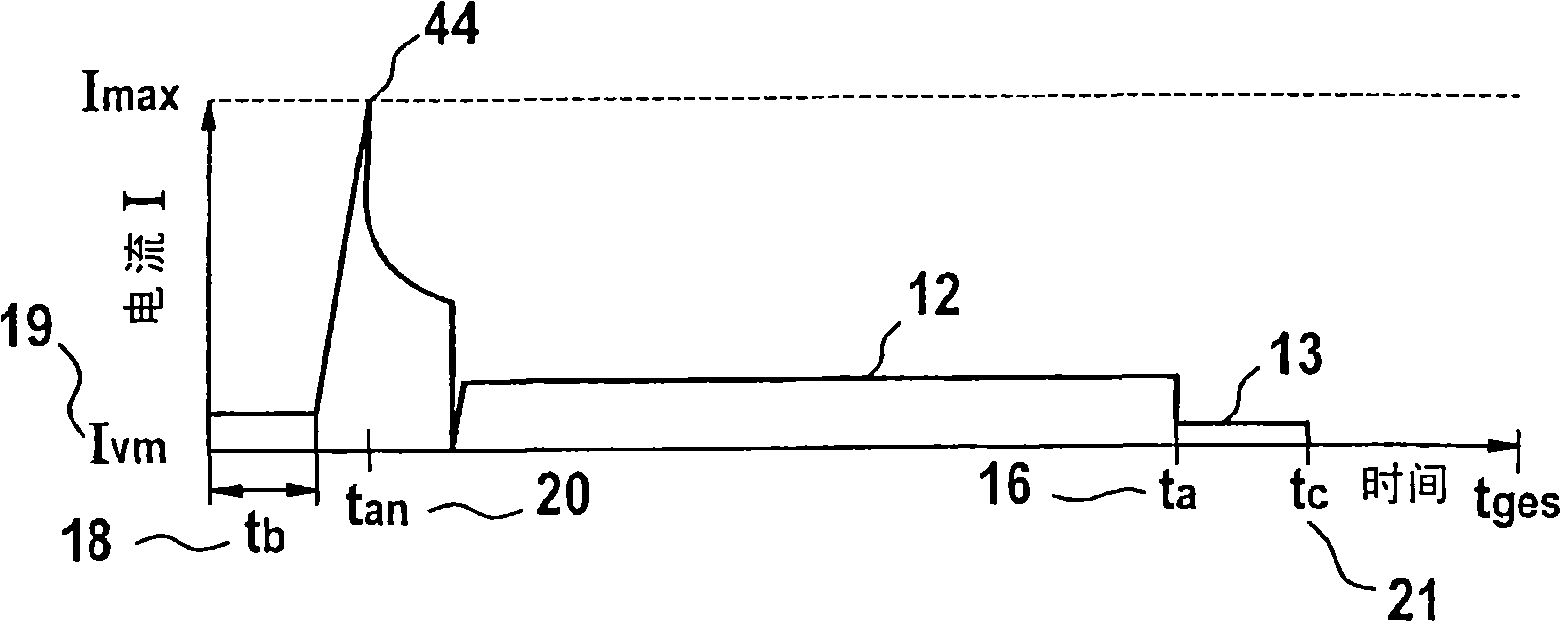

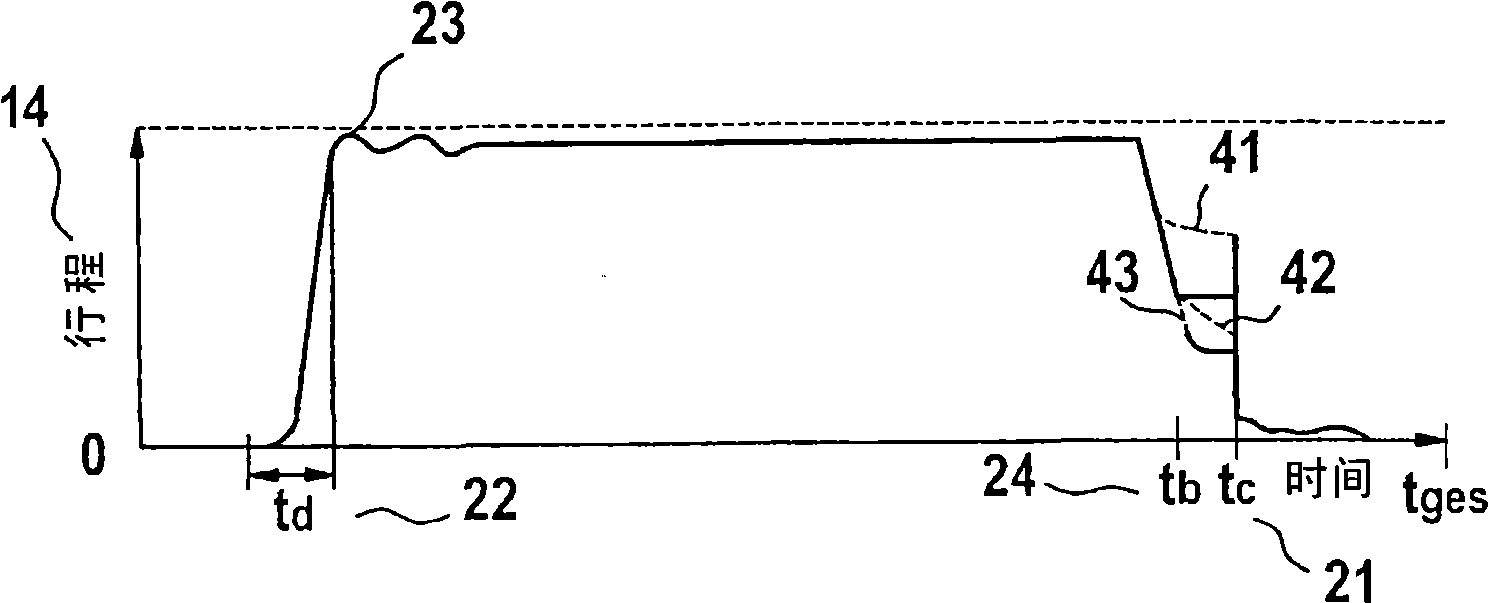

[0019] figure 1 A state-time diagram of an inventive method for targeted injection of fuel is shown, which has an opening phase 10 and a closing phase 11 of a fuel injection valve 2 . In a first method step, a controller 9, which is an integral part of the fuel injection system 1 according to the invention, determines that a total time interval is provided for the opening phase 10 and the closing phase 11 of the fuel injection valve 1 t ges 15. During the time interval t ges Within 15 (this time interval is based on a time interval t a 16 and a time interval t s 17 results in) an opening phase 10 and a closing phase 11 are determined for the fuel injector 2 which correspond to the time interval t a 16 and the state "1" recorded on the ordinate of the state-time diagram, the closing phase corresponds to the time interval t s 17 and the state "0" described on the abscissa of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com