Method for producing whole metal self-locking nut

A technology of self-locking nuts and manufacturing methods, applied in the direction of metal extrusion dies, etc., can solve the problem that all-metal self-locking nuts cannot be used repeatedly for 5 times, and achieve the effect of low specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

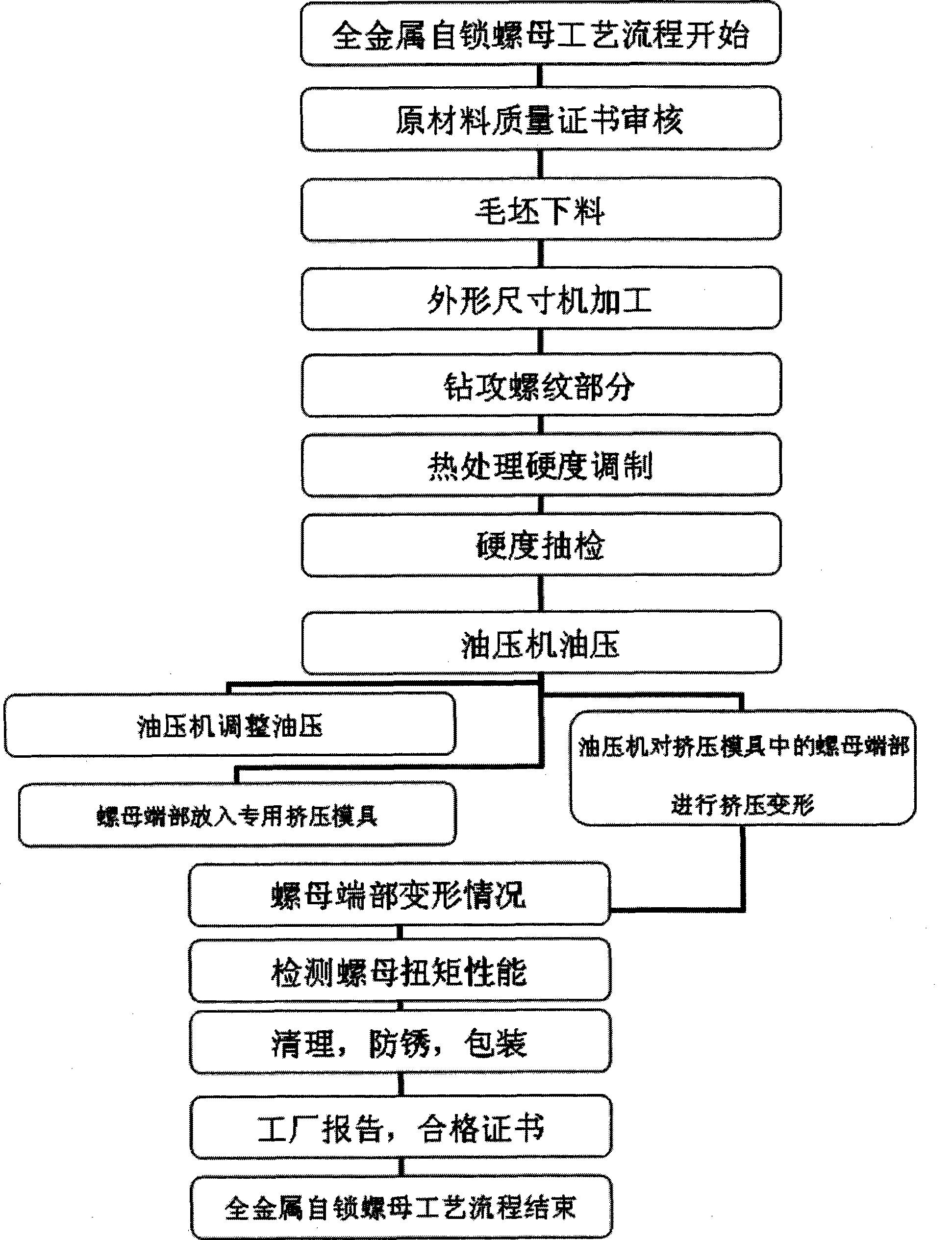

[0037] The manufacturing method of the all-metal self-locking nut of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but this should not limit the protection scope of the present invention.

[0038] The key to the locking function of the all-metal self-locking nut is to deform the nut port into an ellipse through hydraulic extrusion, and to rely on the friction torque generated by itself during the fastening process with the bolt to play an anti-loosening function. The feature of the present invention is that after a large number of tests, a special all-metal self-locking nut port part extrusion die is designed. Under the quantified pressure of the hydraulic press, the nut port part realizes shaped and quantitative deformation, and generates friction torque itself.

[0039] Different metal materials will have different effects on the locking function of all-metal self-locking nuts under different heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com