Combat-readiness floating bridge for mud-stone flow embedded road section and its erection method

A technology for debris flow and silting, which is applied in the field of rapid road repair in debris flow and buried roads, can solve the problems of heavy dredging workload, failure to meet combat readiness requirements, traffic interruption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

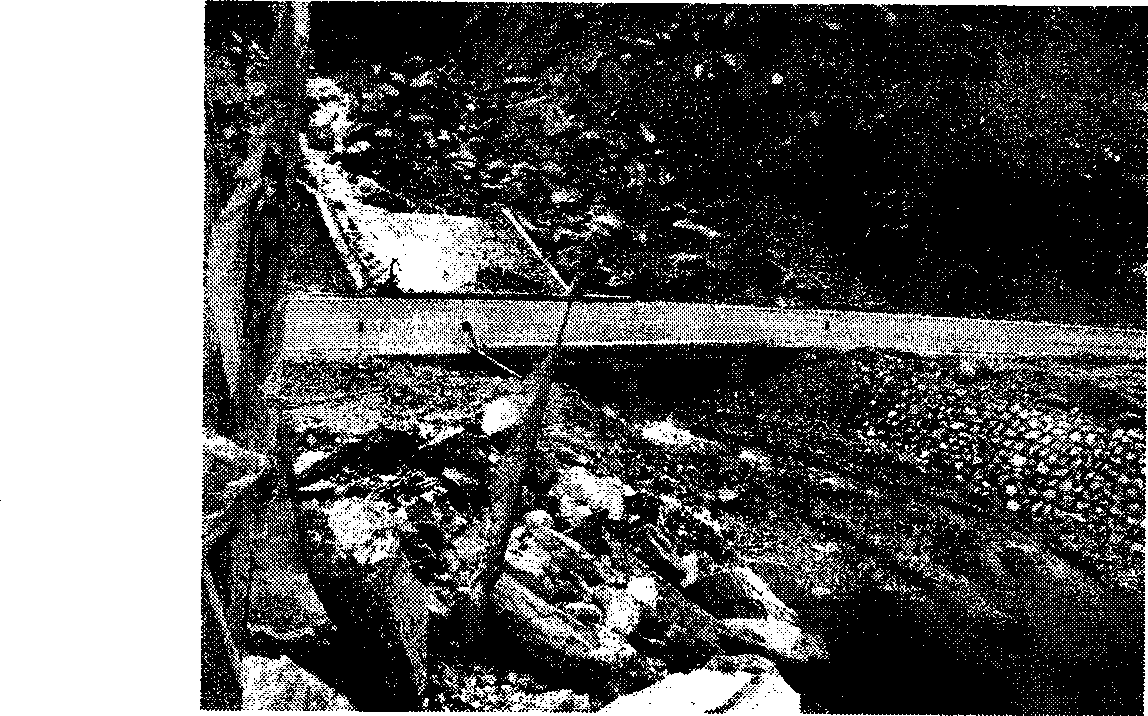

[0028] see Figure 6 , the mud-rock flow silt-buried section combat readiness pontoon bridge of the present invention, structure is as follows: a plurality of load-bearing piers 1 are symmetrically distributed in two rows, each load-bearing pier 1 is connected by connecting rod 2 to form a load-bearing system, and planks are laid on the load-bearing system; The connecting rods 2 described above are laid horizontally, vertically, and crosswise, and each bearing pier 1 is connected to five adjacent bearing piers 1 through the connecting rod 2; the bearing pier 1 and the connecting rod 2 are locked Bolt 1-3 fixed.

[0029] The specific parameters are as follows: the center distance between two columns of bearing piers 1 is 3.0-3.5m; the center distance between two adjacent bearing piers 1 in the same row is 2.5-3.0m, and the number of bearing piers 1 is adjustable; the locking bolts 1-3 include: Screw core and nut, the diameter of the screw core is 8-15cm, and the height of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com